Component gradually changed alloy absorption layer of pyroelectric detector and preparation method thereof

A technology of pyroelectric detectors and composition gradients, applied in the field of absorbing layers, can solve the problems of high reflectivity and high reflectivity of metal absorbing layers, achieve the effects of eliminating reflection phenomena, solving high reflectivity, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

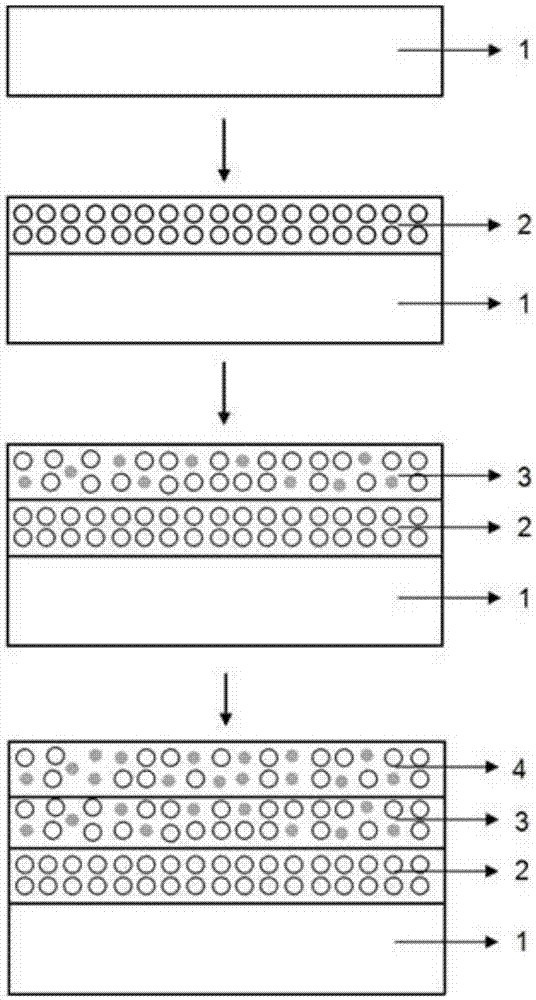

[0032] A method for preparing a pyroelectric detector component graded alloy absorbing layer, comprising the following steps:

[0033] Step 1, preparing a bottom metal film on the top surface of the sensitive element;

[0034] Step 2, preparing a middle metal film on the bottom metal film prepared in step 1, and the refractive index of the middle metal film is smaller than the refractive index of the bottom metal film;

[0035] Step 3, preparing a top metal film on the middle metal film prepared in step 2, and the refractive index of the top metal film is smaller than that of the middle metal film.

[0036] The specific steps of this step one are: using magnetron sputtering method or evaporation method to prepare the bottom metal film on the top surface of the sensitive element, the material of the bottom metal film is one of bismuth, aluminum, titanium, nickel, chromium , the sputtering current of the target material of the bottom metal thin film is 0.8A, and the thickness o...

Embodiment 1

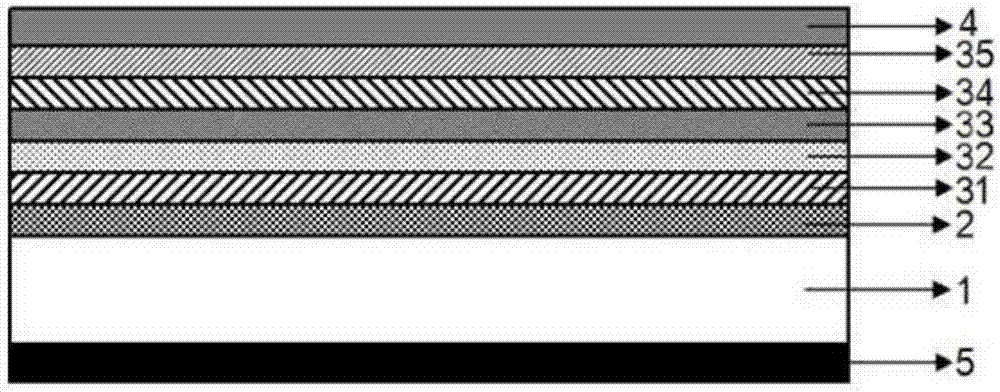

[0042] Such as figure 2 As shown, a pyroelectric detector composition gradient alloy absorber layer, the absorber layer in LiTaO 3 The crystalline flakes are spread out as the top layer of the pyroelectric sensitive unit.

[0043] LiTaO 3 The pre-preparation process of crystal flakes is as follows: in LiTaO 3 Prepare the lower electrode on the wafer; through grinding and polishing for LiTaO 3 The wafer is thinned to form pyroelectric sensitive cells.

[0044] Wash LiTaO 3 Crystal flakes, photolithographically patterned on the upper surface. Using magnetron sputtering technology to prepare chromium film as the bottom metal film, adjust the process pressure to 4Pa, and the sputtering current to 0.8A to obtain a dense chromium metal layer with a refractive index of 3.51, a porosity range of 15%, and a thickness range of Controlled at 10nm, there is better adhesion between the metal chromium and the substrate, which can improve the adhesion of the absorbing layer.

[0045]...

Embodiment 2

[0054] A pyroelectric detector component graded alloy absorber layer, the structure is made of LiTaO 3 A crystalline flake is spread out as the top layer of the pyroelectric sensitive unit 7 .

[0055] LiTaO 3 The pre-preparation process of the crystal sheet is: preparing the lower electrode on the lithium tantalate wafer; thinning the lithium tantalate wafer by grinding and polishing to form a pyroelectric sensitive unit.

[0056] Wash LiTaO 3 Crystal flakes, photolithographically patterned on the upper surface. Magnetron sputtering technology was used to prepare titanium thin film as the bottom metal thin film. The process pressure was adjusted to 4Pa and the sputtering current was 0.8A to obtain a dense titanium metal layer with a porosity of 15% and a thickness of 10nm.

[0057] On the surface of the bottom metal film, double-target sputtering technology is used to prepare the first middle-layer graded aluminum-titanium film. The process pressure is adjusted to 4Pa, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com