Method for preparing multilayer ceramic capacitor

A technology of multilayer ceramics and capacitors, which is applied in the direction of laminated capacitors, etc., can solve the problems of increasing dust on the production site, unfavorable environmental protection and sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

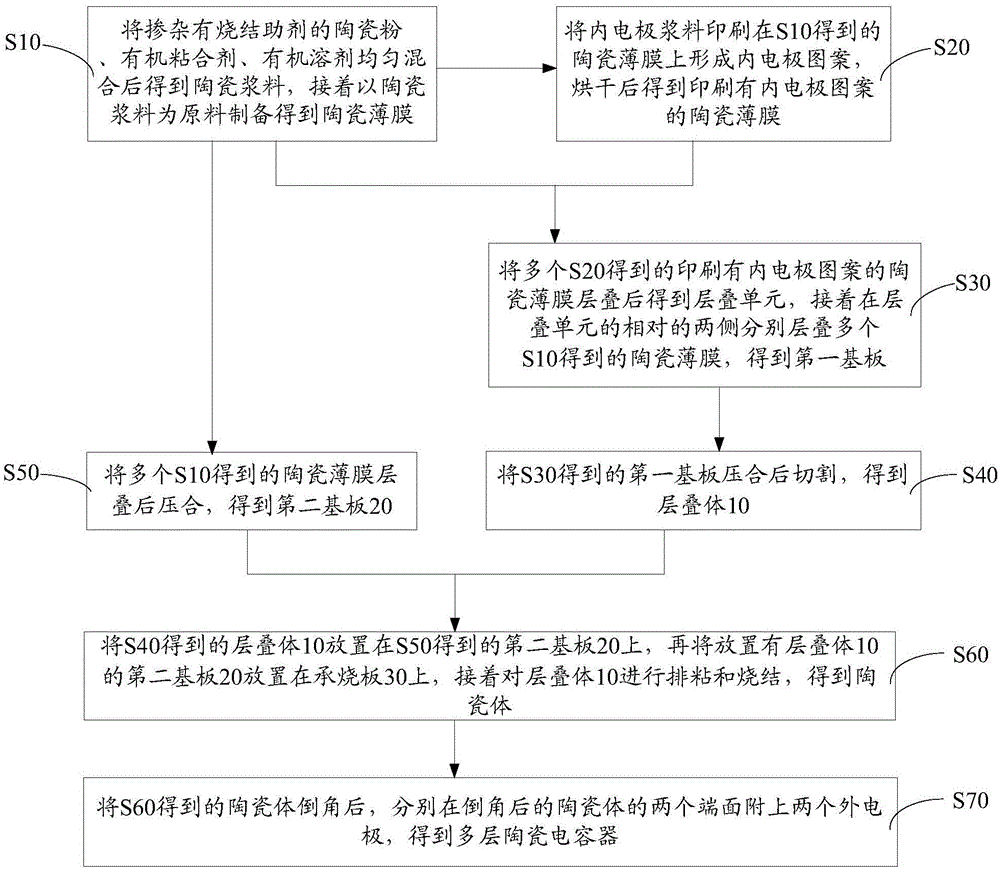

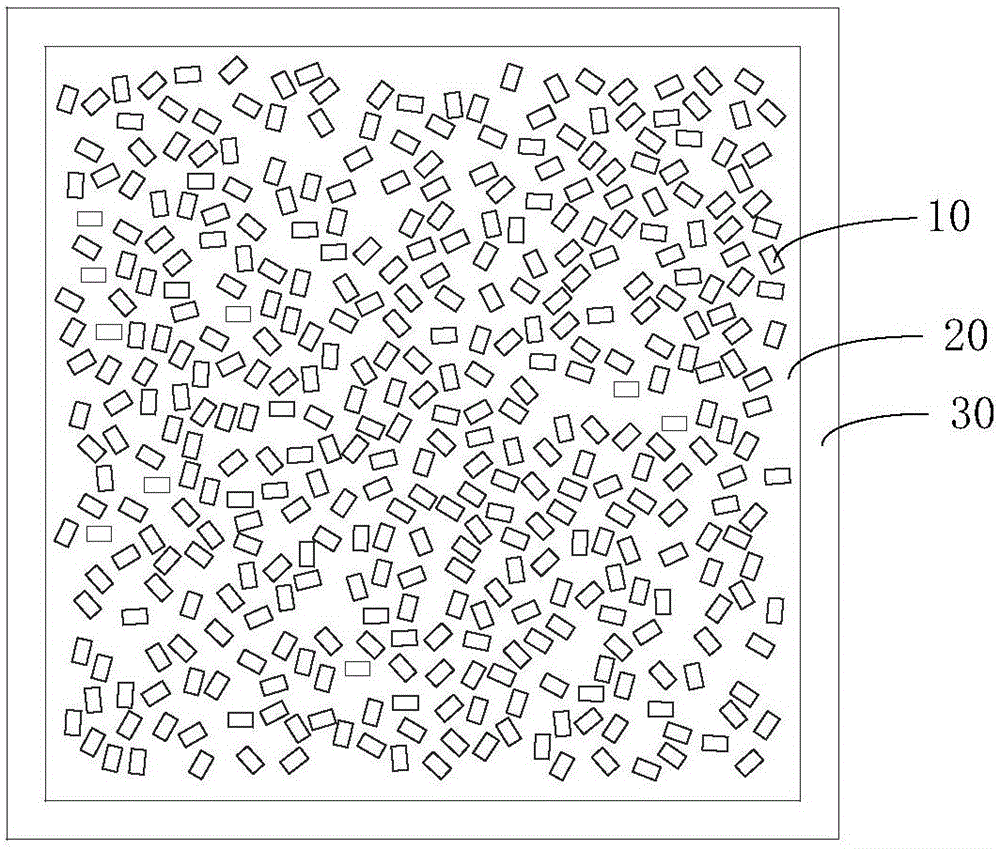

[0026] The preparation method of the multilayer ceramic capacitor will be further described in detail below mainly in conjunction with the accompanying drawings.

[0027] combine figure 1 and figure 2 , the preparation method of the multilayer ceramic capacitor of an embodiment, comprises the steps:

[0028] S10, uniformly mixing the ceramic powder doped with the sintering aid, the binder, and the organic solvent to obtain a ceramic slurry, and then preparing a ceramic thin film by using the ceramic slurry as a raw material.

[0029] In this embodiment, the operation of uniformly mixing the ceramic powder doped with sintering aid, the binder, and the organic solvent is as follows: the ceramic powder doped with the sintering aid, the adhesive, and the organic solvent are uniformly mixed by ball milling , The ball milling time can be 10h ~ 16h.

[0030] In the ceramic slurry, the mass ratio of the ceramic powder doped with the sintering aid, the binder and the organic solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com