A method for preparing lithium-doped cobalt ferrite material using waste lithium battery as raw material

A technology of waste lithium battery and cobalt ferrite, applied in the field of lithium battery, can solve the problems of serious secondary pollution, low product added value, complicated process, etc., and achieve the effects of reducing harm, improving application value, and simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

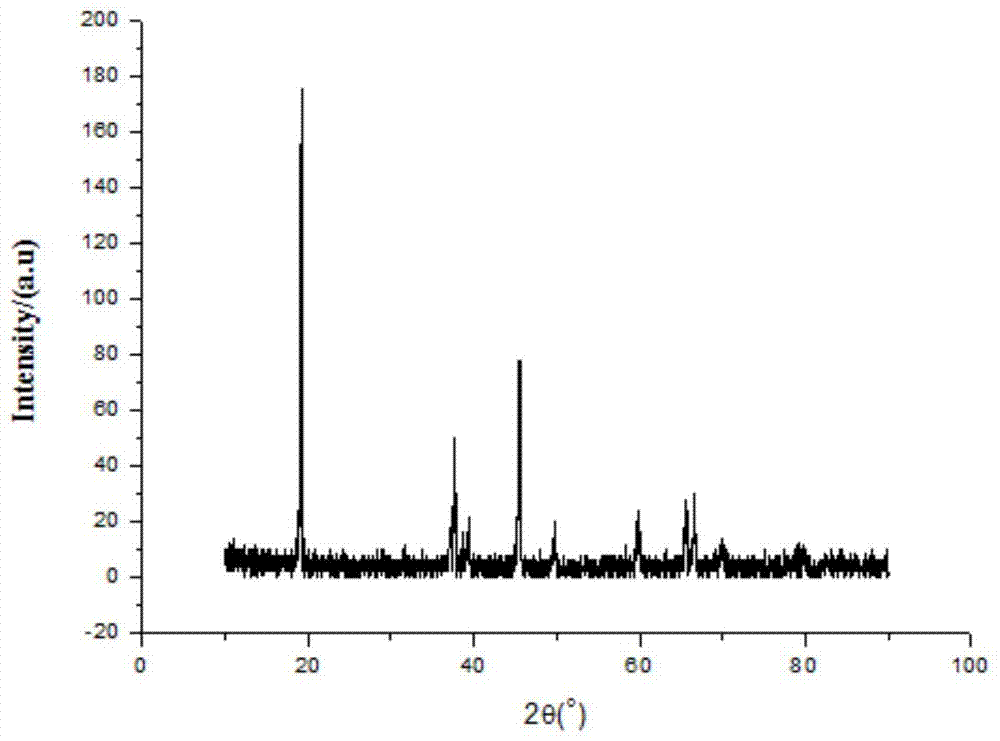

Embodiment 1

[0033] A method for preparing a lithium-doped cobalt ferrite material using waste lithium batteries as a raw material, which specifically includes the following steps:

[0034] (1) Dismantling: dismantling the waste lithium battery to obtain the positive electrode sheet material, that is, the aluminum foil containing the positive electrode material, and the negative electrode sheet material, that is, the copper foil containing the negative electrode material;

[0035] (2), separation of positive electrode sheet material: take 16g of positive electrode sheet material, adopt the nitric acid that mass concentration is 10% to carry out impregnation completely at normal temperature for 30min, take out the positive electrode sheet after impregnating with tweezers, put it in the beaker and use Immerse in ionized water, place the beaker in an ultrasonic cleaning device, adjust the ultrasonic frequency to 45KHz, adjust the temperature to 60°C, and adjust the time to 45min. After ultraso...

Embodiment 2

[0042] A method for preparing a lithium-doped cobalt ferrite material using waste lithium batteries as a raw material, which specifically includes the following steps:

[0043] (1) Dismantling: dismantling the waste lithium battery to obtain the positive electrode sheet material, that is, the aluminum foil containing the positive electrode material, and the negative electrode sheet material, that is, the copper foil containing the negative electrode material;

[0044] (2), separation of positive electrode sheet material: take 16g of positive electrode sheet material, adopt the nitric acid that mass concentration is 10% to carry out impregnation completely at normal temperature for 30min, take out the positive electrode sheet after impregnating with tweezers, put it in the beaker and use Immerse in ionized water, place the beaker in an ultrasonic cleaning device, adjust the ultrasonic frequency to 45KHz, adjust the temperature to 60°C, and adjust the time to 45min. After ultraso...

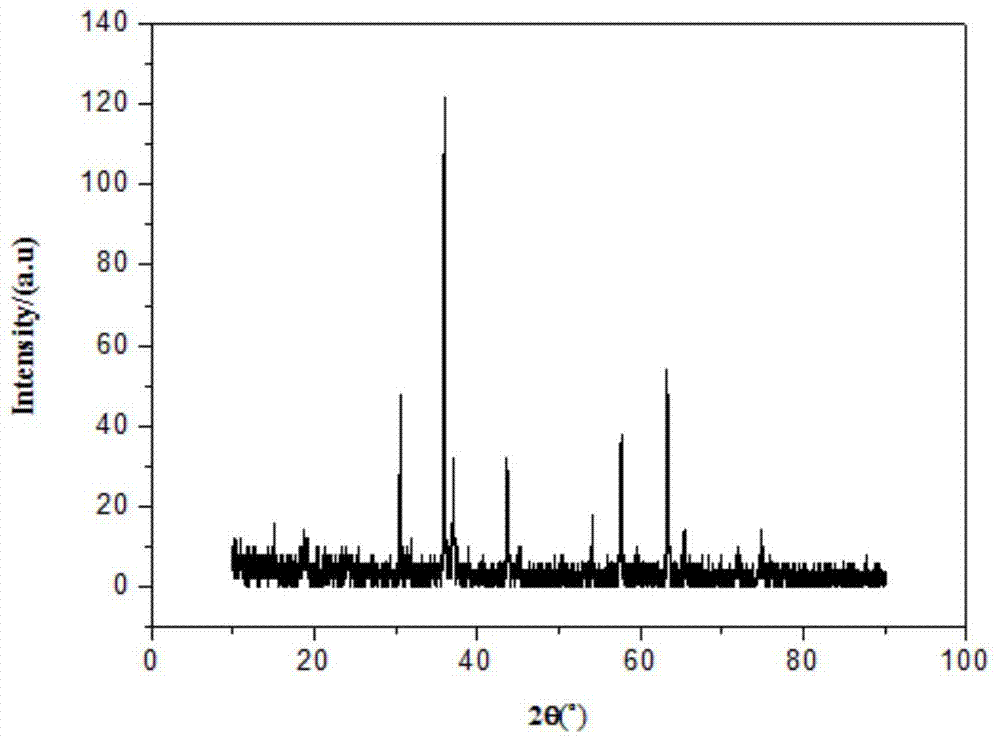

Embodiment 3

[0050] A method for preparing a lithium-doped cobalt ferrite material using waste lithium batteries as a raw material, which specifically includes the following steps:

[0051] (1) Dismantling: dismantling the waste lithium battery to obtain the positive electrode sheet material, that is, the aluminum foil containing the positive electrode material, and the negative electrode sheet material, that is, the copper foil containing the negative electrode material;

[0052] (2), separation of positive electrode sheet material: take 16g of positive electrode sheet material, adopt the nitric acid that mass concentration is 10% to carry out impregnation completely at normal temperature for 30min, take out the positive electrode sheet after impregnating with tweezers, put it in the beaker and use Immerse in ionized water, place the beaker in an ultrasonic cleaning device, adjust the ultrasonic frequency to 45KHz, adjust the temperature to 60°C, and adjust the time to 45min. After ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com