Clamping method of pre-welding purifier

A pre-welding purifier and process technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of high cost, and achieve the effect of being easy to move up and down and fix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

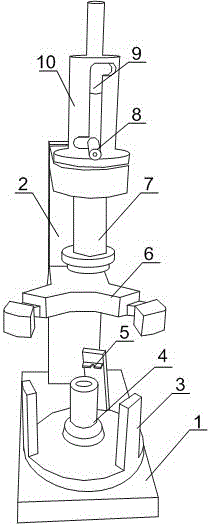

[0019] Such as figure 1 As shown, a clamping method of a pre-welding purifier of the present invention is realized through the following steps: the clamping process is: first, the semi-finished steel plate that has completed the reel process is manually placed on the clamp, and the arc on the mast 2 shaped bayonet 6 for positioning, and finally under the fixing action of the pressing mechanism, manual welding is started to complete the manufacture of the finished purifier shell, wherein the fixture includes a base 1, a mast 2, a support mechanism, an arc bayonet 6, Press-down mechanism, the base 1 is vertically connected with the mast 2, the support mechanism is arranged on the base 1, the arc bayonet 6 is arranged in the middle of the mast 2, the top of the mast 2 is provided with a press-down mechanism, the support mechanism, the arc The axis lines of the shaped bayonet socket 6 and the pressing mechanism coincide. The semi-finished steel plate that has completed the rollin...

Embodiment 2

[0021] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the support mechanism includes a support column 4 and a plurality of support plates 3 , and the plurality of support plates 3 are distributed around the support column 4 in a circular array. The function of the support column 4 set in the middle of the support plate 3 is to guide the semi-finished steel plate of the necking to be accurately placed on the welding position, and the surrounding support plate 3 fixes the steel plate itself, so as to avoid the displacement of the semi-finished steel plate when the necking is welded. welding effect.

Embodiment 3

[0023] Such as figure 1 As shown, this embodiment is based on the embodiment 2, and the top of the support plate 3 is also provided with a protrusion 5 . The protrusion 5 at the bottom of the support plate 3 acts as a limiter. During welding, it is inevitable that it will collide with the semi-finished steel plate of the neck. The protrusion 5 can well limit the semi-finished steel plate of the neck between the support plate 3 and the support plate. between the columns 4 to prevent their displacement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com