Pressing and smashing machine for obtaining wood fiber

A wood fiber and mechanical technology, applied in the field of wood fiber crushing machinery, can solve problems such as unsatisfactory processing effect, lower performance, damage to wood fiber, etc., and achieve the effects of motion balance, reduced elastic recovery, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

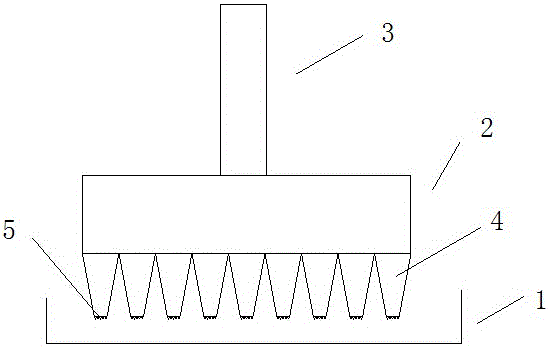

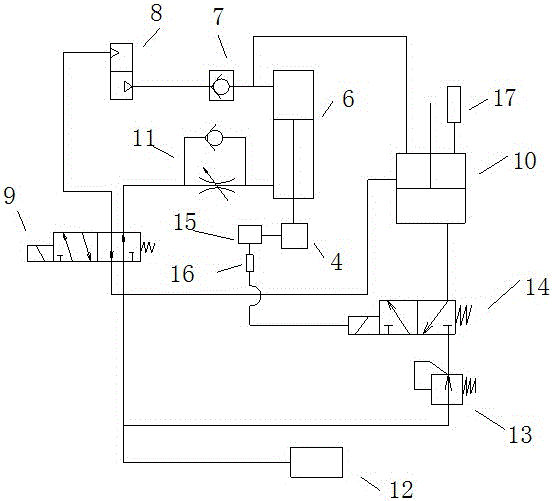

[0013] A wood fiber crushing machine, as attached figure 1 And attached figure 2 As shown, it includes a mechanical part and a hydraulic part. The mechanical part includes a wood chip tank 1, a fixed block 2 is arranged above the wood chip tank 1, a pressing handle 3 is arranged above the fixed block 2, and a plurality of trapezoidal pressing blocks 4 are arranged below the fixed block 2. Pressing teeth 5 are arranged below the pressing block 4; the hydraulic part includes an air-liquid cylinder 6 connected to the pressing handle 3, and the rodless end of the air-liquid cylinder 6 is connected with an air-controlled one-way valve 7, and the air-controlled one-way The valve 7 is connected with a gas-liquid converter 8, and the gas-liquid converter 8 is connected with a two-position five-way electromagnetic reversing valve 9, and the gas-liquid converter 8 and the two-position five-way electromagnetic reversing valve 9 P The two-position five-way electromagnetic reversing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com