Soybean-based carbon quantum dot and porous carbon material as well as preparation method therefor and application thereof

A carbon quantum, soybean-based technology, applied in the field of material science, can solve the problem of underutilization of biomass, and achieve the effect of being conducive to large-scale production, wide application and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

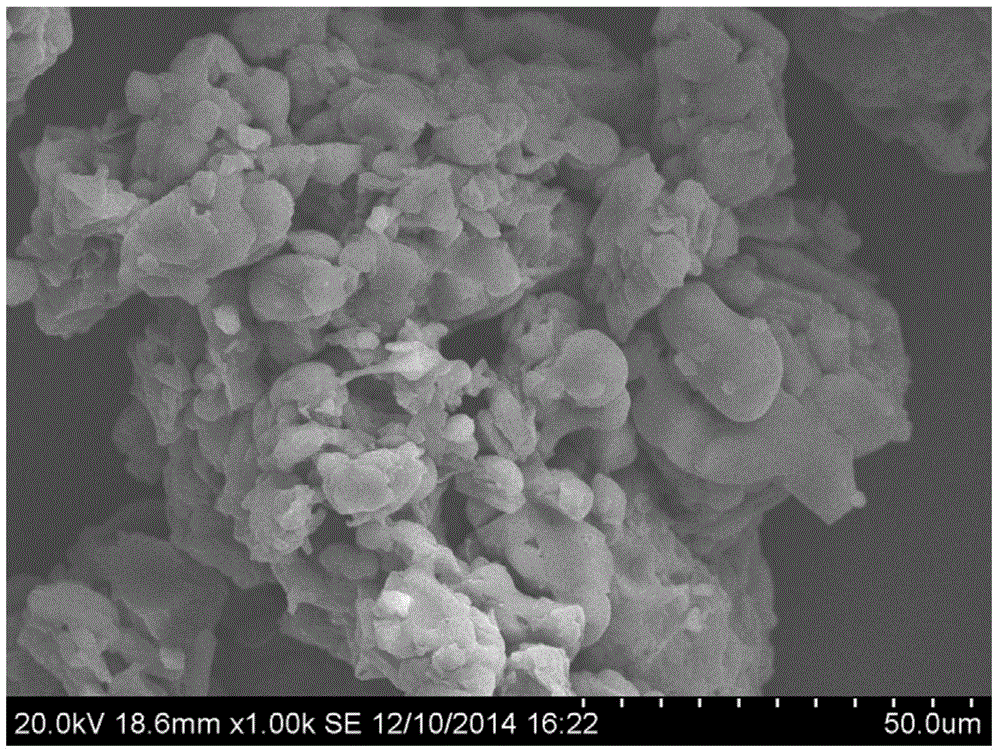

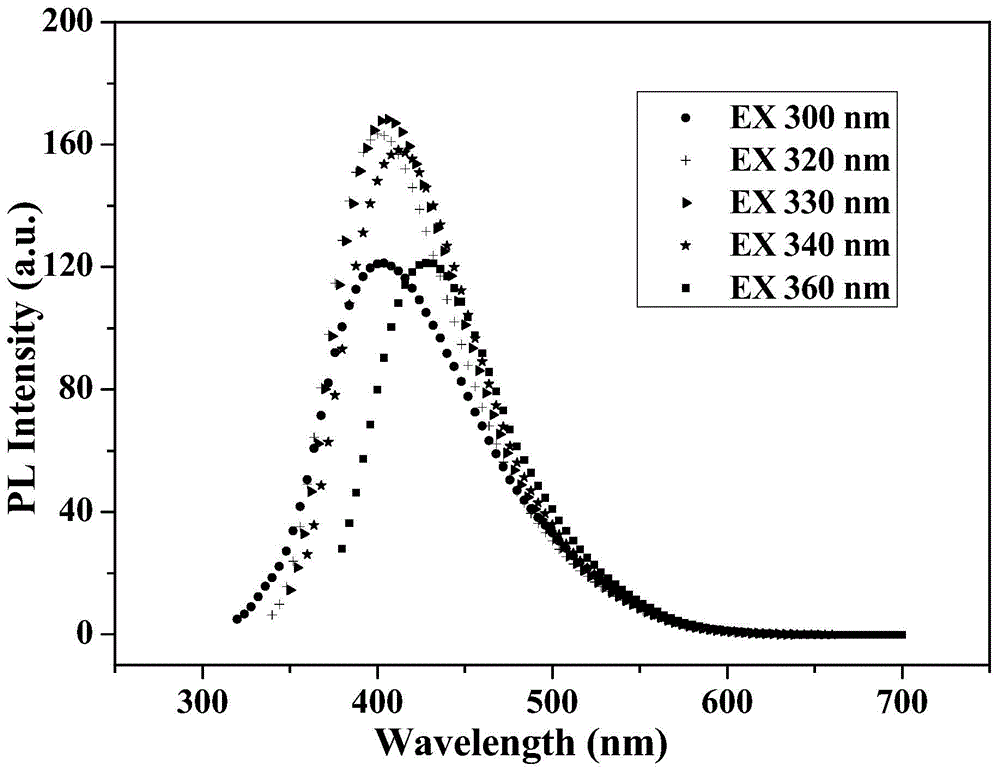

[0033] (1) Put the crushed soybeans into a boat-shaped sample tank, place it in an atmosphere tube furnace, evacuate the furnace, and carry out low-temperature carbonization in an argon atmosphere, and the flow rate of argon is 0.5L / min , the heating rate is 5°C / min, the temperature is raised to 200°C, and the treatment time is 3h. Then the carbonized product under the condition is dispersed in water, soaked and stirred for 3 hours, centrifuged to obtain supernatant and sediment residue, and the supernatant is filtered with a microporous membrane to obtain soybean-based carbon quantum dot aqueous dispersion.

[0034] (2) The precipitate residue was dried in an oven at 80°C for 6h, and the dried residue was carbonized at 750°C for 1.5h in an argon atmosphere, the gas flow rate was 0.5L / min, and the heating rate was 5°C / min. The obtained product was washed 5 times with 2M hydrochloric acid, then washed with water until neutral, and dried at 80° C. for 12 hours to obtain a soybea...

Embodiment 2

[0037] (1) Put the crushed soybeans into a boat-shaped sample tank, place it in an atmosphere tube furnace, evacuate the furnace, and carry out low-temperature carbonization in an argon atmosphere, and the flow rate of argon is 0.5L / min , the heating rate is 5°C / min, the temperature is raised to 200°C, and the treatment time is 3h. Then the carbonized product under this condition is dispersed in water, soaked and stirred for 3 hours, centrifuged to obtain the supernatant and sediment residue, the supernatant is filtered with a microporous membrane, and then further dialyzed with a 500 dialysis bag to obtain soybean Based carbon quantum dot aqueous dispersion.

[0038] (2) Dry the precipitate residue in an oven at 80°C for 6h, mix the dried residue with KOH solid at a mass ratio of 0.5:1, soak in water for 10h, and then dry at 100°C. The dried sample was put into a boat-shaped sample tank, and carbonized at 750 °C for 1.5 h in an argon atmosphere, with a gas flow rate of 0.5 L...

Embodiment 3

[0042](1) Put the crushed soybeans into a boat-shaped sample tank, place it in an atmosphere tube furnace, evacuate the furnace, and carry out low-temperature carbonization in an argon atmosphere, and the flow rate of argon is 0.5L / min , the heating rate is 5°C / min, the temperature is raised to 300°C, and the processing time is 3h. Then the carbonized product under this condition is dispersed in water, soaked and stirred for 5 hours, centrifuged to obtain the supernatant and sediment residue, the supernatant is filtered with a microporous membrane, and further dialyzed with a 500 dialysis bag to obtain soybean Based carbon quantum dot aqueous dispersion.

[0043] (2) Dry the precipitate residue in an oven at 80°C for 6h, mix the dried residue with KOH solid at a mass ratio of 1:1, soak in water for 10h, and then dry at 100°C. Put the dried sample into the boat-shaped sample tank, and in the atmosphere of argon, first carbonize at 300°C for 1h, the heating rate is 5°C / min, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com