Latent aroma compound with sweet and nutty aroma and its preparation method and application

A compound and latent aroma technology, applied in the field of tobacco flavor, can solve the problems of inability to use tobacco formulations well, unstable cigarette quality, poor heat-resistant processability, etc., and achieve the effects of rich varieties, small molecular weight, and high volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

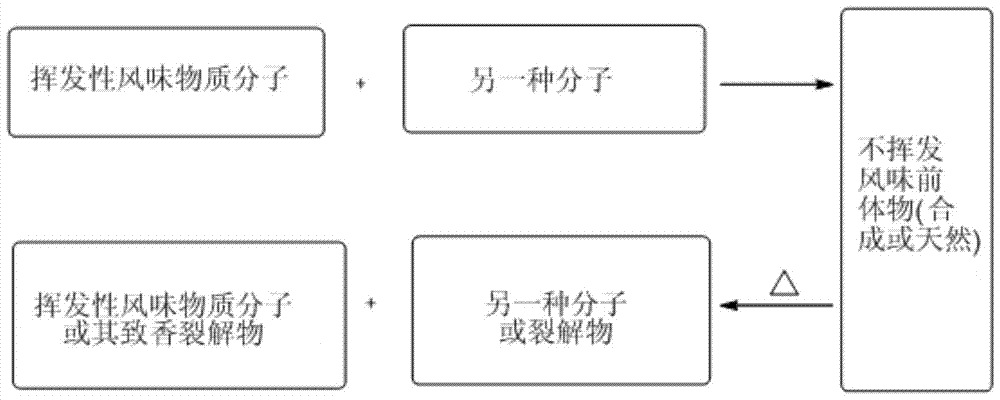

Problems solved by technology

Method used

Image

Examples

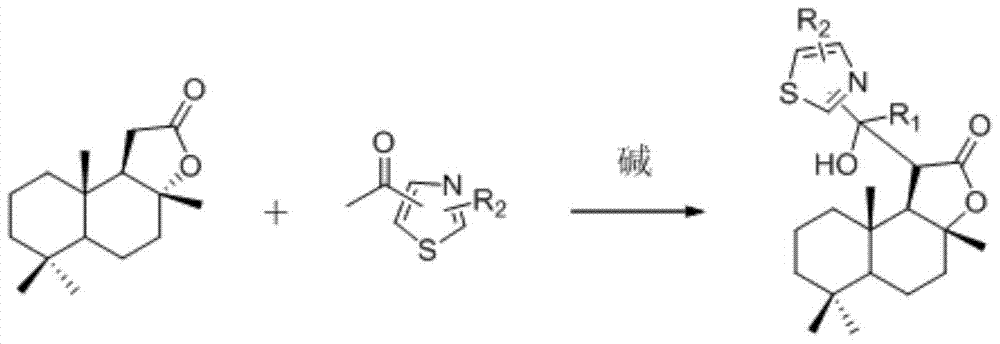

Embodiment 1

[0040] Add 8ml of anhydrous diethyl ether and 0.311ml (2.2mmol) of diisopropylamine in a 50ml round bottom flask, cool the solution to -60°C, then drop BuLi (2.2mmol) in 2.5N n-hexane solution into the upper reaction system, Raise the reaction system to 0°C and stir for 15min, then add the ether solution of norambrolide (500mg, 2.0mmol) dropwise at -60°C, continue to stir the reaction system for 40min, then add 2-acetylthiazole (254.3mg, 2.0 mmol) ether solution was added dropwise to the reaction system. Stir the reaction system at this temperature for 50 min, quench the reaction with water, separate the organic layer, wash with saturated salt, dry over anhydrous sodium sulfate, filter, distill off the solvent under reduced pressure, and separate the residue by silica gel column chromatography to obtain CYL-2- QX-3A, the yield is 60.0%.

[0041] 1 HNMR (CDCl 3 ):δ, ppm 0.59(td, J=12.4Hz, J=3.6Hz 1H), 0.74(s,3H), 0.83(s,3H), 0.88(s,3H), 0.89~0.93(m,1H) ,1.00~1.05(m,3H),1.24...

Embodiment 2

[0045] Add 8ml of anhydrous diethyl ether and 0.311ml (2.2mmol) of diisopropylamine in a 50ml round bottom flask, cool the solution to -60°C, then drop BuLi (2.2mmol) in 2.5N n-hexane solution into the upper reaction system, The reaction system was raised to 0°C and stirred for 15min, then a solution of norbroxolide (500mg, 2.0mmol) in ether was added dropwise at -60°C, and the reaction system was stirred for 40min, then 2,4-dimethyl-5 - Ether solution of acetylthiazole (310.4mg, 2.0mmol) was added dropwise to the above reaction system. Stir the reaction system at this temperature for 50 min, quench the reaction with water, separate the organic layer, wash with saturated brine, dry over anhydrous sodium sulfate, filter, distill off the solvent under reduced pressure, and separate the residue by silica gel column chromatography to obtain CYL-2- QX-3B, yield 57.0%.

[0046] ESI-MS(positive ion mode)(rel.int.)m / z:406([M+H] + ,100).

Embodiment 3

[0048] Add 8ml of anhydrous diethyl ether and 0.311ml (2.2mmol) of diisopropylamine in a 50ml round bottom flask, cool the solution to -60°C, then drop BuLi (2.2mmol) in 2.5N n-hexane solution into the upper reaction system, The reaction system was raised to 0°C and stirred for 15 minutes, then a diethyl ether solution of norambrolide (500mg, 2.0mmol) was added dropwise at -60°C, and the reaction system was stirred for 40 minutes, then 4-acetylthiazole (254.3.4mg, 2.0 mmol) of ether solution was added dropwise to the reaction system. Stir the reaction system at this temperature for 50 min, quench the reaction with water, separate the organic layer, wash with saturated salt, dry over anhydrous sodium sulfate, filter, distill off the solvent under reduced pressure, and separate the residue by silica gel column chromatography to obtain CYL-2- QX-3C, yield 55.0%.

[0049] ESI-MS(positive ion mode)(rel.int.)m / z:378([M+H] + ,100).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com