Bubble dispersion method for preparing graphene/epoxy resin composite materials

An epoxy resin and composite material technology, applied in the field of nanocomposite materials, can solve the problems of adverse effects on the mechanical properties of composite materials, affecting the effective range of ultrasonic waves, difficult to adapt to large-scale production needs, etc. Reasonable way and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

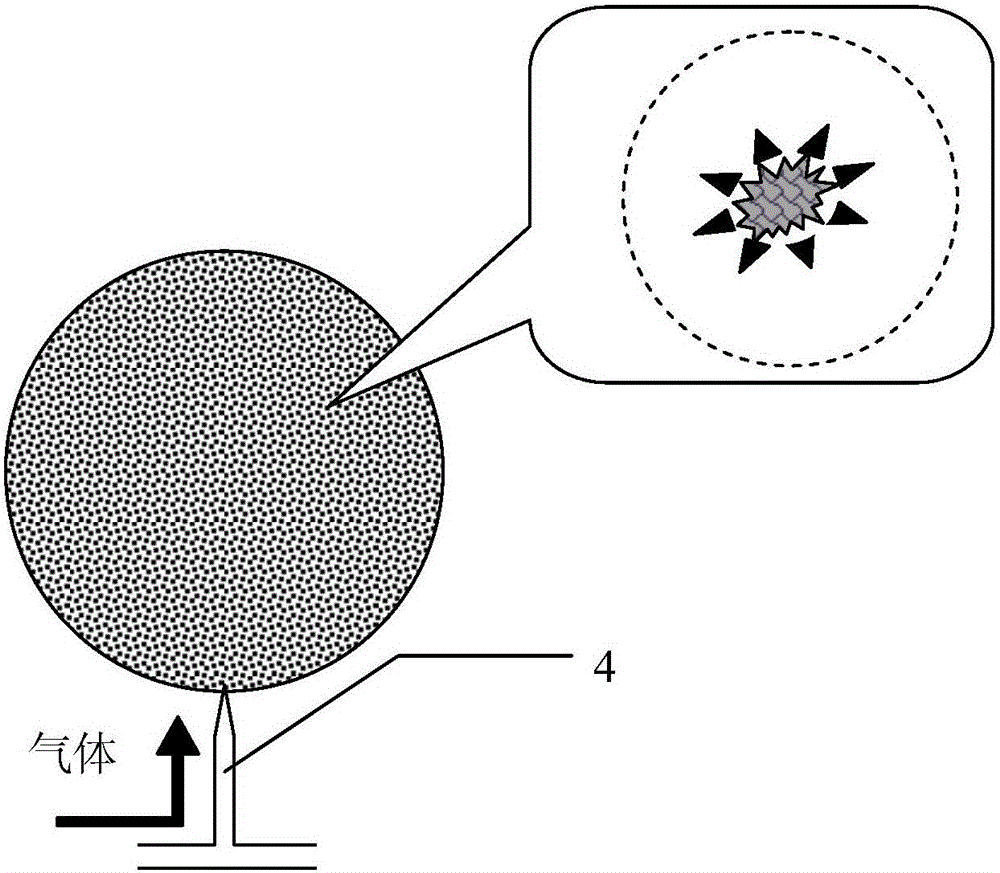

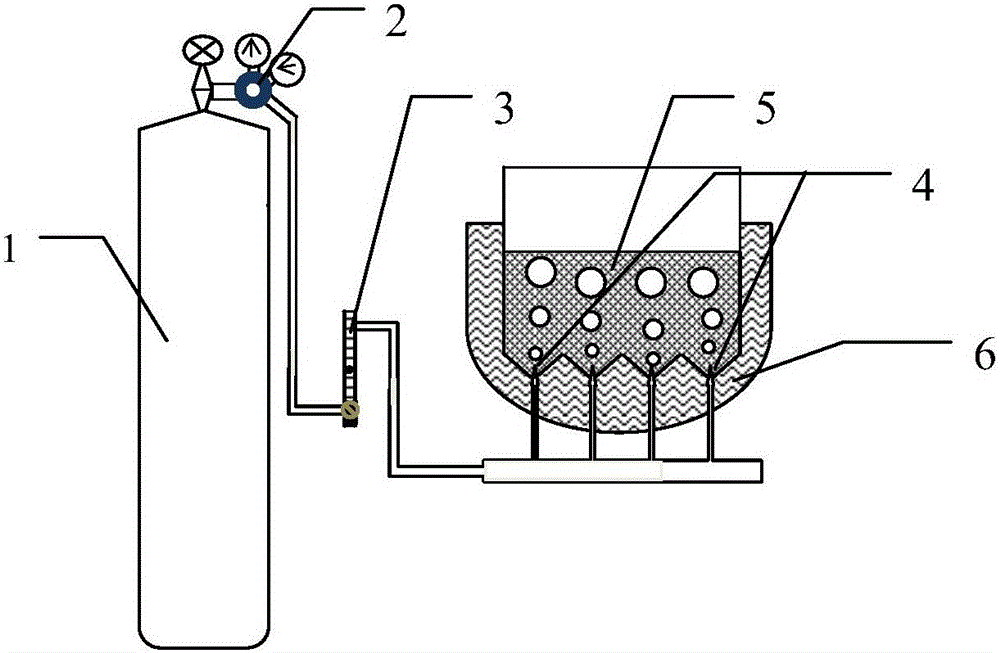

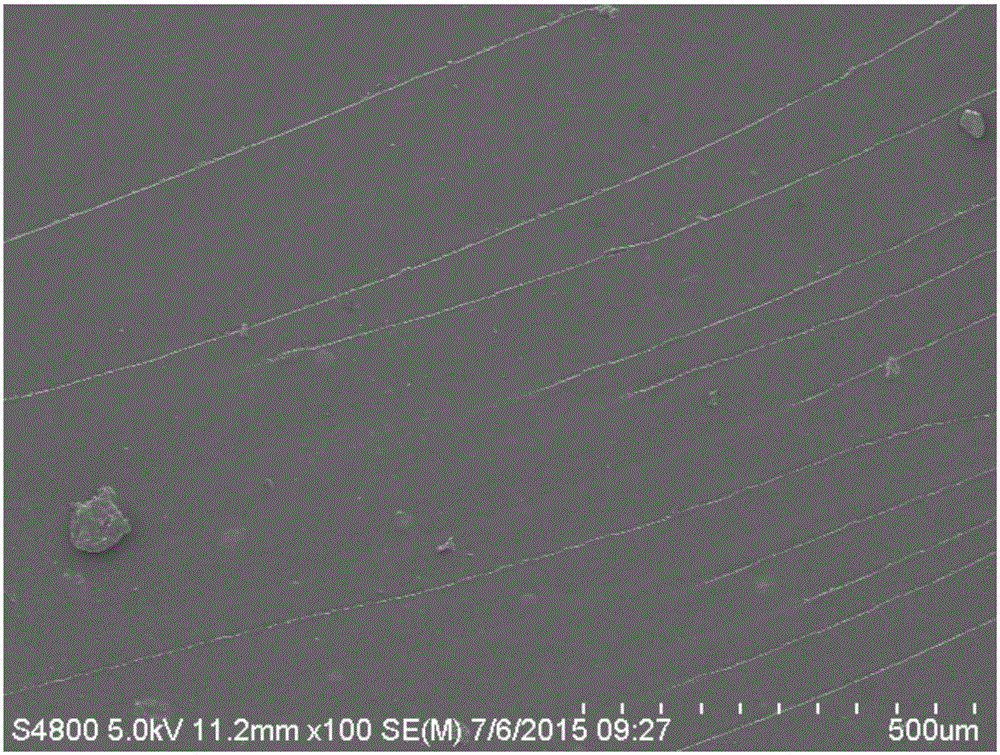

Embodiment 1

[0035] Weigh 100 parts of epoxy resin and 0.15 parts of graphene, that is, the mass ratio of graphene to epoxy resin is 0.15%, so that graphene is premixed in epoxy resin. Set the temperature of the water bath to 55°C. After the temperature is constant, open the valve of the compressed air cylinder, adjust the pressure reducing valve and the flow meter to keep the flow rate at 400mL / min / gas nozzle (the number of gas nozzles in this embodiment is 15) , each air nozzle has a flow rate of 400mL per minute, arranged in a honeycomb shape on the bottom of the sample pool, with a distance of 3cm), pour the prepared graphene / epoxy resin mixture into the sample pool of the bubble dispersion device, to avoid local uneven dispersion , carry out bubbling for 6h; until bubbling for 5 hours and 50 minutes, take 10 parts of triethylenetetramine (10% of the mass of epoxy resin) and add to the sample pool, continue to bubbling to 4h; Put it in a vacuum drying oven at 80°C, perform vacuum defoa...

Embodiment 2

[0037] Weigh 100 parts of epoxy resin and 0.45 parts of graphene, that is, the mass ratio of graphene to epoxy resin is 0.45%, so that graphene is premixed in epoxy resin. Set the temperature of the water bath to 80°C. After the temperature is constant, open the valve of the compressed air cylinder, adjust the pressure reducing valve and the flow meter to keep the flow rate at 1000mL / min / gas nozzle (the number of gas nozzles in this embodiment is 20) , arranged in a honeycomb shape on the bottom surface of the sample pool, with a distance of 5 cm), pour the prepared graphene / epoxy resin mixture into the sample pool of the bubble dispersion device, to avoid local uneven dispersion, bubbling for 2 hours; until bubbling for 1 hour 1 hour and 50 minutes, weigh 10 parts of triethylenetetramine (10% of the mass of the epoxy resin) and add it to the sample cell, and continue to aerate for 2 hours; After defoaming treatment for 1 hour, take it out, solidify and mold at room temperatur...

Embodiment 3

[0039] Weigh 100 parts of epoxy resin and 1.5 parts of graphene, that is, the mass ratio of graphene to epoxy resin is 1.50%, so that graphene is premixed in epoxy resin. Set the temperature of the water bath to 55°C. After the temperature is constant, open the valve of the compressed air cylinder, adjust the pressure reducing valve and the flow meter to keep the flow rate at 200mL / min / gas nozzle (the number of gas nozzles in this embodiment is 30) , arranged in a honeycomb shape on the bottom surface of the sample pool, with a distance of 4cm), pour the prepared graphene / epoxy resin mixture into the sample pool of the bubble dispersing device, avoid local uneven dispersion, and bubble for 12 hours; until bubble 11 1 hour and 50 minutes, weigh 10 parts of triethylenetetramine (10% of the mass of epoxy resin) and add it to the sample cell, and continue to blow air for 12 hours; After 2 hours of defoaming treatment, take it out, solidify and mold at room temperature for 24 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com