Preparation methods of coating solution with high corrosion resistance and hot-dipped aluminum-zinc plate with finger resistance

A coating liquid, high corrosion resistance technology, applied in the direction of coating, metal material coating process, anti-corrosion coating, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

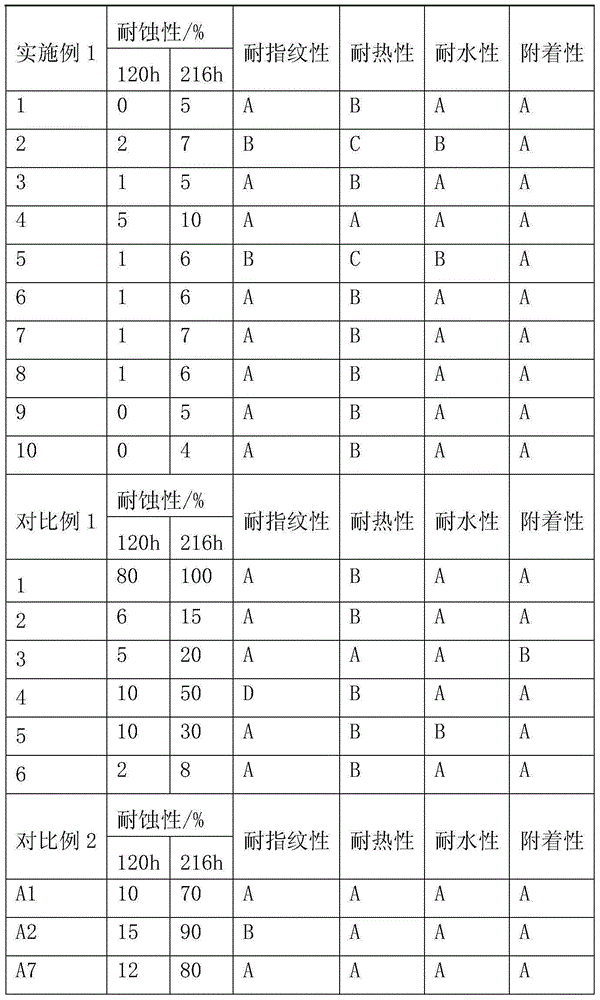

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned high-corrosion-resistant coating liquid is firstly dissolving chromic anhydride in water, then adding phosphate, after dissolving, adding oxo acid salt, then adding a pH regulator, and adjusting the pH to 8-11 Add colloidal silicon dioxide, and finally add water-based organic resin emulsion, and stir evenly to obtain the high corrosion resistance coating liquid of the present invention. In the present invention, the pH is adjusted to 8-11 to ensure the stability of the coating liquid, because the coating liquid contains chromate, and the chromate will automatically oxidize organic matter under acidic conditions, reducing the stability of the coating liquid , forming adverse phenomena such as coagulation and discoloration, in order to avoid these adverse phenomena, it needs to be prepared in an alkaline environment.

[0036] The preparation method of the hot-dip aluminum-zinc anti-fingerprint plate of the present invention co...

Embodiment 1

[0043] 1. Preparation of high-corrosion-resistant coating solution and heat transfer aluminum-zinc anti-fingerprint board

[0044] 1. Preparation of high corrosion resistance coating solution:

[0045] First weigh each component according to the content of each component of the high corrosion resistance coating solution in Table 1, then dissolve chromic anhydride in water, then add phosphate, add oxo acid salt after dissolving, then add pH regulator, Adjust the pH to 8-11, then add colloidal silicon dioxide, and finally add water-based organic resin emulsion, and stir evenly to obtain the high corrosion-resistant coating liquid prepared by the present invention.

[0046] 2. Preparation of hot-dip galvanized anti-fingerprint board:

[0047] Include the following steps:

[0048] a, prepare the hot-dip galvanized sheet substrate by conventional methods;

[0049] B, roll coating or spray coating liquid on the hot-dip galvanized sheet substrate prepared in a step; The coating li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com