Novel two-stage type converter gas waste heat recovery system

A waste heat recovery system and converter gas technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve problems such as high system safety requirements, achieve enhanced heat transfer effects, increase sensible heat recovery rate, and increase gas flow speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0023] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

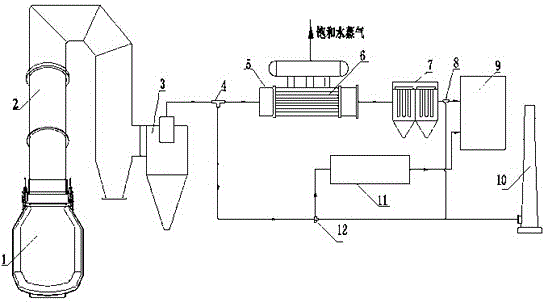

[0024] Such as figure 1 The new two-stage converter gas waste heat recovery system shown sequentially includes a connected converter 1, a converter flue 2, a high-temperature cyclone separator 3, a fire-tube type natural circulation converter gas waste heat boiler 6, and a gas dust removal and purification device 7. The gas dedusting and purification device 7 is connected to the converter gas storage cabinet 9 and the chimney 10 through the first three-way switching valve 8 respectively. It also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com