Gas curtain control type flue dust collecting apparatus

A dust collection and control technology, applied in coating, metal material coating process, hot-dip galvanizing process, etc., can solve the problems of high energy consumption, unbearable, galvanizing stagnation, etc., achieve high collection rate and convenient use , the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

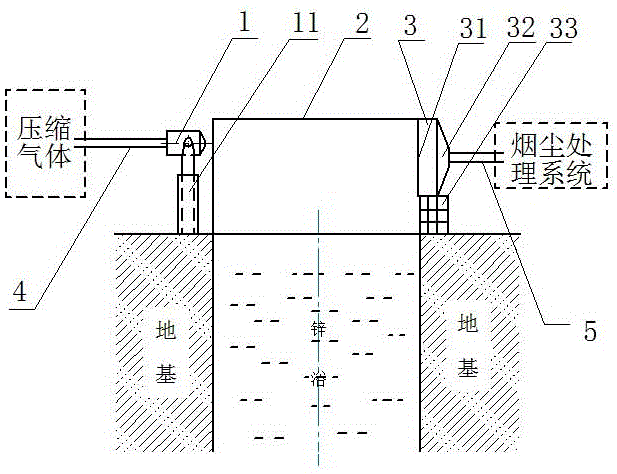

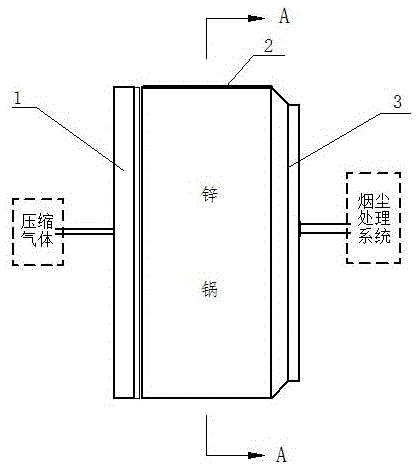

[0024] Dimensions of the zinc pot: length × width × depth is 10m × 1.5m × 2m, the air curtain control type smoke and dust collection device includes the gas nozzle 1 and the bracket 11 supporting the gas nozzle 1, the baffle plate 2, the bellows 3 and the bracket 33 supporting the bellows 3 , intake pipeline 4, exhaust pipeline 5.

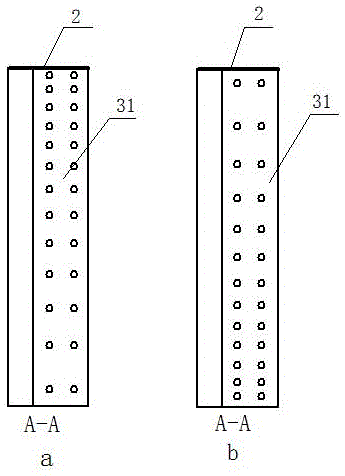

[0025] The air nozzle 1 and the bellows 3 are respectively installed on both sides of the zinc pot. The air inlet of the air nozzle 1 is connected to the air inlet pipeline 4. The air outlet of the air nozzle 1 is in the shape of a slit, and the direction of the air outlet is in the horizontal direction. The length of the air outlet is is 10m. The baffle plate 2 is installed on the end of the zinc pot, the length of the baffle plate 2 is 1.5m, and the top of the baffle plate 2 is flush with the top of the bellows 3. The air inlet 31 of the bellows 3 is opposite to the air outlet of the air nozzle 1, and through holes are distributed on the partiti...

Embodiment 2

[0027] Dimensions of the zinc pot: length × width × depth is 16m × 2m × 2.5m, the air curtain control type smoke and dust collection device includes the gas nozzle 1 and the bracket 11 supporting the gas nozzle 1, the baffle plate 2, the bellows 3 and the bracket 33 supporting the bellows 3 , intake pipeline 4, exhaust pipeline 5.

[0028] The air nozzle 1 and the bellows 3 are respectively installed on both sides of the zinc pot. The air inlet of the air nozzle 1 is connected to the air inlet pipe 4. The air outlet of the air nozzle 1 is in the shape of a slit, and the angle between the direction of the air outlet and the horizontal direction is 15°. , the length of the air outlet is 16m. The baffle plate 2 is installed on the end of the zinc pot, the length of the baffle plate 2 is 2m, and the top of the baffle plate 2 is flush with the top of the bellows 3 . The air inlet 31 of the bellows 3 is opposite to the air outlet of the air nozzle 1, and through holes are distribut...

Embodiment 3

[0030] Dimensions of the zinc pot: length x width x depth 7m x 1.8m x 2.0m. The air nozzle 1 and the bellows 3 are respectively installed on both sides of the zinc pot. The air inlet of the air nozzle 1 is connected to the air inlet pipeline 4. The air outlet of the air nozzle 1 is in the shape of a slit, and the angle between the direction of the air outlet and the horizontal direction is 10° , the length of the air outlet is 7m. The baffle plate 2 is installed on the end of the zinc pot, the length of the baffle plate 2 is 1.8m, and the top of the baffle plate 2 is flush with the top of the bellows 3 . The air inlet of the bellows 3 is opposite to the air outlet of the air nozzle 1, and through holes are distributed on the partition plate of the air inlet 31 of the bellows 3, from the baffle plate 2 of the zinc pot to the other end of the zinc pot on the partition of the air inlet 31 of the bellows 3 The distribution density of vias gradually decreases (eg image 3 Middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com