A kind of capacitive pressure sensor and preparation method thereof

A pressure sensor and capacitive technology, applied in the field of electronics, can solve the problems of small deformation of the elastic insulating layer and increase the deformation of the elastic insulating layer, etc., to achieve the effects of increased sensitivity, increased pressure range and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

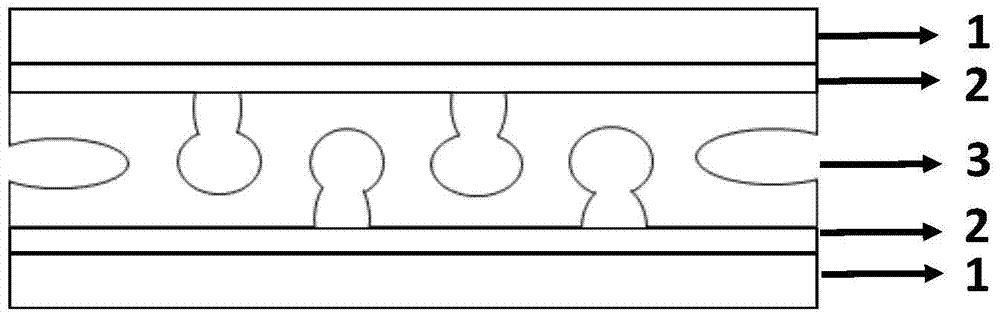

[0035] The preparation method of capacitive pressure sensor of the present invention comprises the following steps:

[0036] 1) The substrate 1 is ultrasonically cleaned with ethanol solution, acetone solution and deionized water, dried after cleaning, and the surface of the substrate 1 is treated with oxygen plasma or ultraviolet light / ozone.

[0037] 2) Prepare the electrode 2 on the substrate 1 by means of vacuum evaporation, magnetron sputtering, spin coating, spray coating, doctor blade coating or gravure printing.

[0038] 3) Attach two substrates 1 containing electrodes 2 to the upper and lower sides of the porous elastic film as the insulating layer 3 to obtain the required capacitive pressure sensor; wherein the electrodes 2 are in contact with the porous elastic film, and the lining Bottom 1 is the outermost.

[0039] The preparation method of the porous elastic film formed after the heat-cured elastic material is mixed with the foaming material comprises the follow...

Embodiment 1

[0047] In this embodiment, a porous elastic film formed by mixing a thermosetting elastic material and a foaming material and then heating and curing is used. The thermosetting elastic material is polydimethylsiloxane (PDMS), and the foaming material is azobisisobutyronitrile. The mixing ratio of the thermosetting elastic material to the foaming material is 10:1. The preparation method of the porous elastic film is as described above.

[0048] Complete the preparation of the capacitive pressure sensor through the following specific steps:

[0049] (1) Utilize ethanol solution, acetone solution and deionized water to clean the flexible transparent substrate 1 of polyethylene terephthalate (PET), blow dry with dry nitrogen after cleaning, and adopt oxygen plasma or ultraviolet Light / ozone treatment of the substrate surface;

[0050] (2) Prepare silver nanowire electrodes on the substrate 1 by spin coating;

[0051] (3) Attach two PET substrates containing silver nanowire ele...

Embodiment 2

[0053] In this embodiment, a porous elastic film formed by mixing a thermosetting elastic material and a foaming material and then heating and curing is used. The thermosetting elastic material is polyurethane (PU), and the foaming material is toluenesulfonyl hydrazide. The mixing ratio of the thermosetting elastic material to the foaming material is 10:2. The preparation method of the porous elastic film is as described above.

[0054] Complete the preparation of the capacitive pressure sensor through the following specific steps:

[0055] (1) Utilize ethanol solution, acetone solution and deionized water to clean the flexible transparent substrate 1 of polyethylene naphthalate (PEN), blow dry with dry nitrogen after cleaning, and adopt oxygen plasma or ultraviolet light / Ozone treatment of the substrate surface;

[0056] (2) Prepare single-walled carbon nanotube electrodes on the substrate by spin coating;

[0057] (3) Attach two PEN substrates containing single-walled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com