Fiber laser intensity noise suppressing device and working method thereof

A fiber laser and intensity noise technology, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems of increasing the system noise floor, affecting detection accuracy and sensitivity, and achieving the effect of suppressing intensity noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

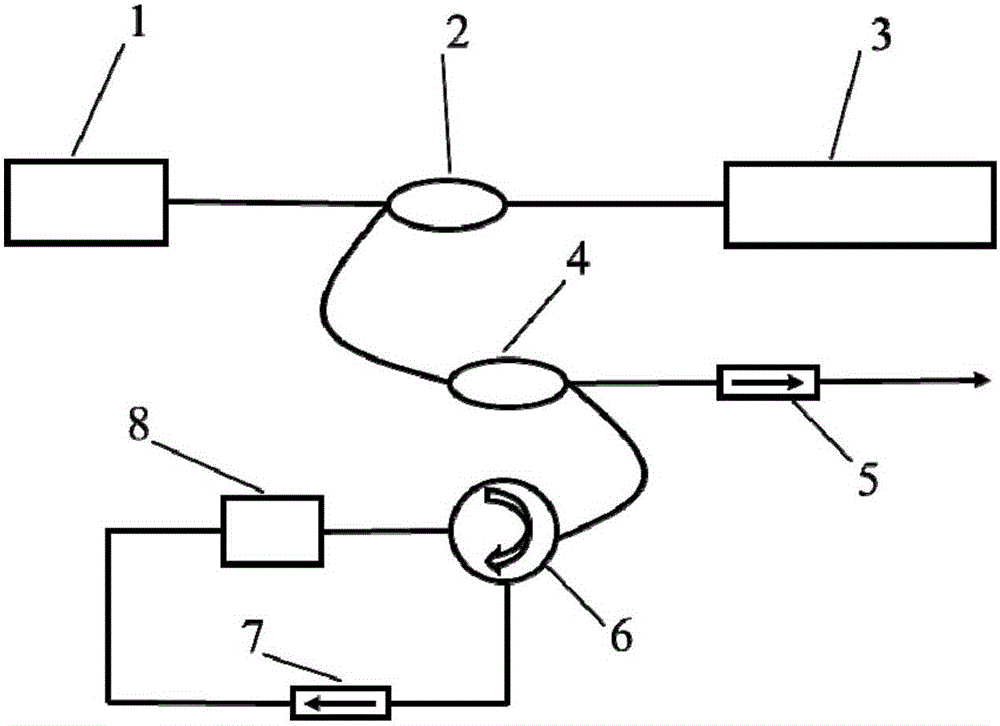

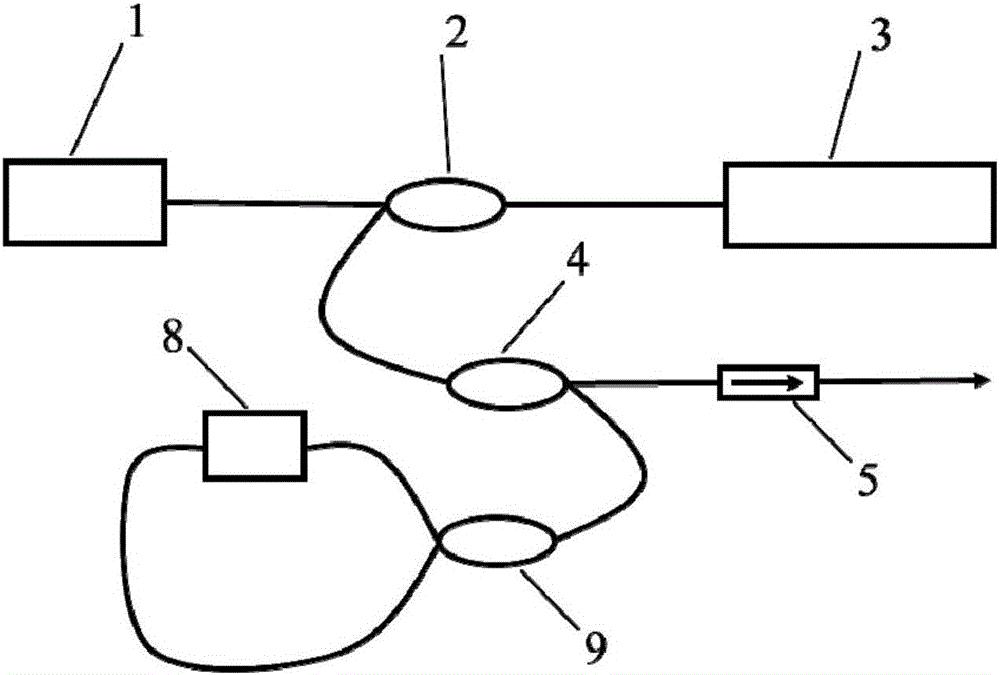

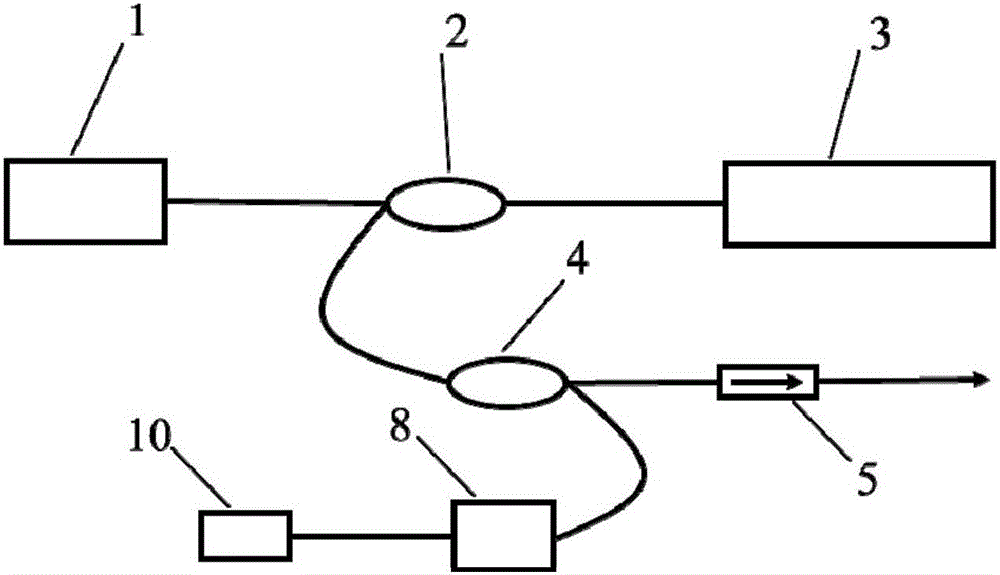

[0025] Figure 1-Figure 4 It is a schematic structural diagram of a device for suppressing intensity noise of a fiber laser according to an embodiment of the present invention. Among them, the pump light output by the single-mode semiconductor pumping light source 1 pumps the fiber resonator 3 through the wavelength division multiplexer 2, and the laser signal generated by the fiber resonator 3 is transmitted from the signal end of the wavelength division multiplexer 2 to Fiber coupler 4, wherein the large end of fiber coupler 4 is output as laser through fiber isolator 5, while the small end of fiber coupler 4 is transmitted to port 3 through port 2 of fiber optic circulator 6, and then through fiber isolator 7 Enter the laser intensity noise suppression device 8 for intensity noise suppression processing, and finally connect to port 1 of the fiber optic circulator 6, and inject it into the fiber resonator 3 after passing through the fiber coupler 4 and the wavelength divisio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com