Amino acid beverage and preparation method thereof

An amino acid and free amino acid technology, applied in the field of amino acid-containing beverages and their preparation, can solve problems such as single function, confusion, and imperfect design of nutritional units, and achieve the effects of not easy water separation, ideal drinking effect, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Preparation method of amino acid drink

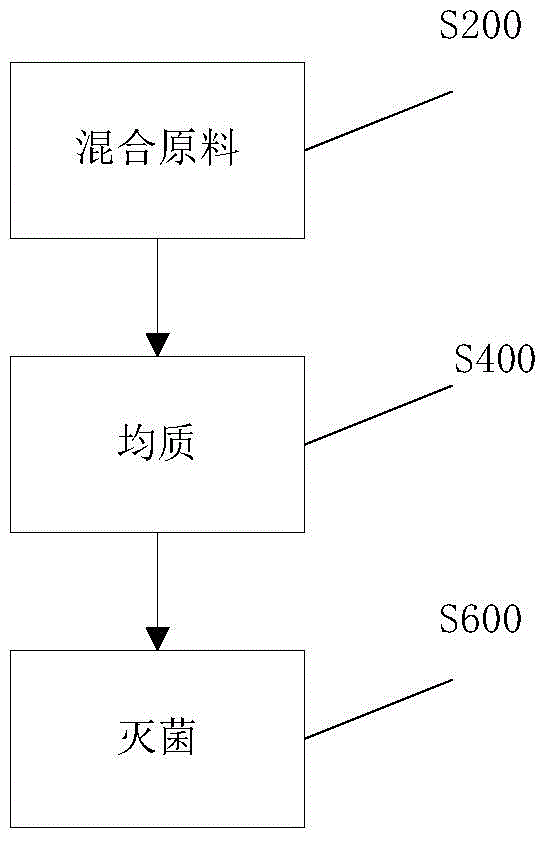

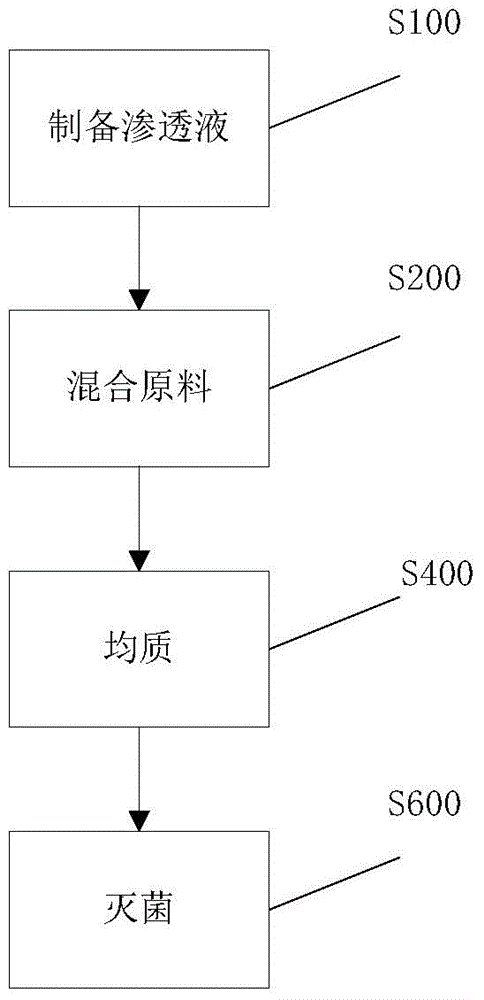

[0044] refer to figure 1 According to one embodiment of the present invention, the method for preparing the amino acid beverage in any embodiment of the present invention includes the following steps:

[0045] S200 mixed raw materials

[0046] In this step, the raw materials are mixed to obtain a mixed material liquid. The raw materials included and their relative weight proportions are: 700-883 parts by weight of permeate, 3-110 parts by weight of sugar, and 1-12 parts by weight of collagen peptide. The so-called permeate contains free amino acids and comes from cow's milk. The permeate is obtained by performing primary filtration and secondary filtration on the milk, and the secondary filtration is ultrafiltration. The so-called cow's milk can be raw cow's milk or reconstituted milk. Raw cow's milk is preferably selected as the main source of amino acids of the drink, and the nutritional value of raw cow's milk is higher t...

Embodiment 1

[0060] 1. Raw materials

[0061] Permeate: 883 kg,

[0062] Vitamin C: 1 kg,

[0063] Soybean polysaccharide: 3 kg,

[0064] Collagen Peptides: 3 kg,

[0065] Juice: 10 kg,

[0066] High fructose syrup: 0 kg,

[0067] White sugar: 100 kg,

[0068] Sugar substitute: 0 kg;

[0069] 2. Preparation method

[0070] 2.1 Preparation of permeate

[0071] Inspect and accept milk according to the national standard GB19301 raw milk standard.

[0072] 1) Coarse filtration: Filter the milk through the filter hole filter to remove relatively large impurities such as cow hair and weeds.

[0073] 2) Purification: After the milk cleaning machine equipment, according to the density difference of the milk components, under the action of centrifugal force, the fine impurities with high density are removed, and the number of spores and somatic cells is reduced at the same time. Operating parameters of milk cleaning machine equipment: equipment flow rate 5000l / h, pressure 0.6Mpa, centrifu...

Embodiment 2

[0088] 1. Raw materials

[0089] Permeate: 856.8 kg, prepared according to 2.1 of Example 1;

[0090] Vitamin C: 2 kg;

[0091] Soybean polysaccharide: 4 kg;

[0092] Collagen peptides: 2 kg;

[0093] Juice: 15 kg;

[0094] White sugar: 20 kg;

[0095] High fructose syrup: 100 kg

[0096] Sugar substitute: 0.2 kg

[0097] 2. Preparation method

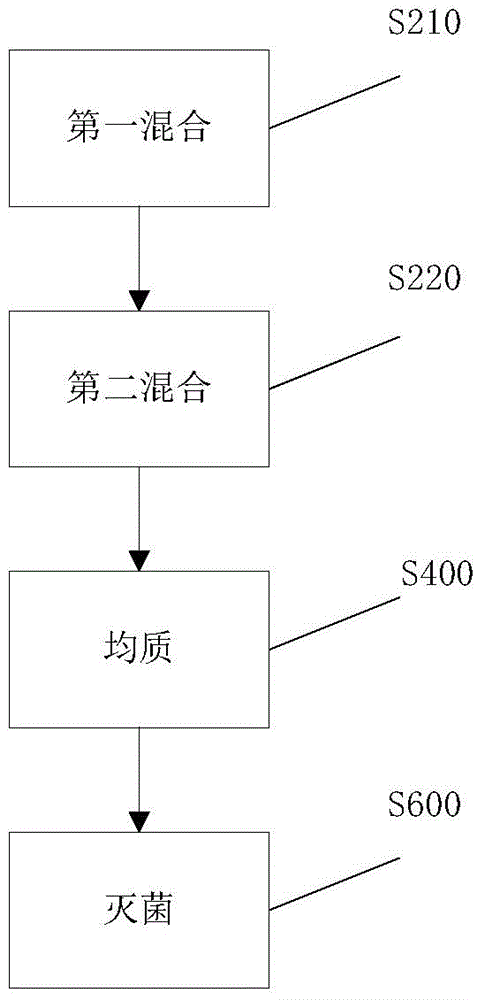

[0098] a. Add white granulated sugar, collagen peptide, and soybean polysaccharide to the permeate in turn, mix evenly and add sugar substitute;

[0099] b. Take the formula amount of fruit juice, fructose syrup, and vitamin C, and continue to mix with the liquid a;

[0100] c. Warm up the homogeneous mixture to 60-65°C;

[0101] d. Use a homogenizer for homogenization, the homogenization temperature is 60-65°C, and the homogenization pressure is 180-220bar;

[0102] e. be fixed to 1000 parts by weight with permeate;

[0103] f. After the purified water is adjusted to 1000kg, it is cooled and filled after sterilization. Ster...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com