Allisartan isoproxil solid dispersion and pharmaceutical composition

A technology of solid dispersion and allisartan medoxomil, which is applied in the directions of drug combinations, sugar-coated pills, pharmaceutical formulations, etc., can solve the problem of low drug loading in solid dispersions, failure to achieve clinical administration weight and antihypertensive effect, and poor patient compliance. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

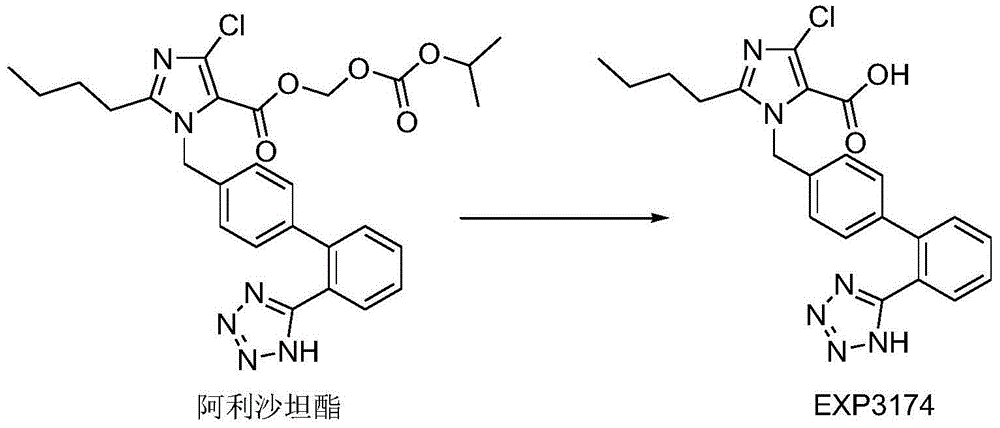

Problems solved by technology

Method used

Image

Examples

Embodiment 1

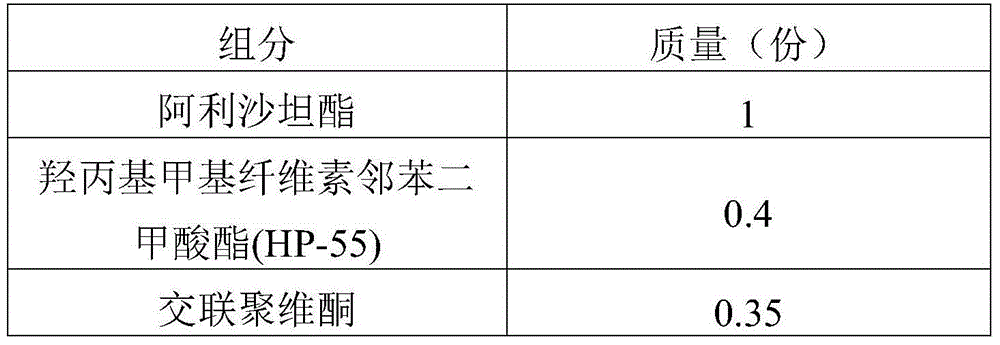

[0043] prescription:

[0044]

[0045] preparation:

[0046] 1. Preparation of solid dispersion

[0047] Dissolve the medicine and Povidone K29 / 32 in an appropriate amount of dichloromethane-ethanol mixed solution, add cross-linked Povidone (I) in the fluidized bed, and spray the prepared solution into the fluidized bed with a spray gun. In-bed granulation and drying to obtain a solid dispersion of allisartan medoxomil; further XRD experiments found that the active ingredient of allisartan medoxomil was highly dispersed in the solid dispersion, proving that the preparation effect of the solid dispersion reached expectations.

[0048] 2. Preparation of pharmaceutical composition

[0049] The solid dispersion is uniformly mixed with other materials, pressed into tablets to obtain plain tablets, and film-coated to obtain the alisartan medoxomil pharmaceutical composition.

Embodiment 2

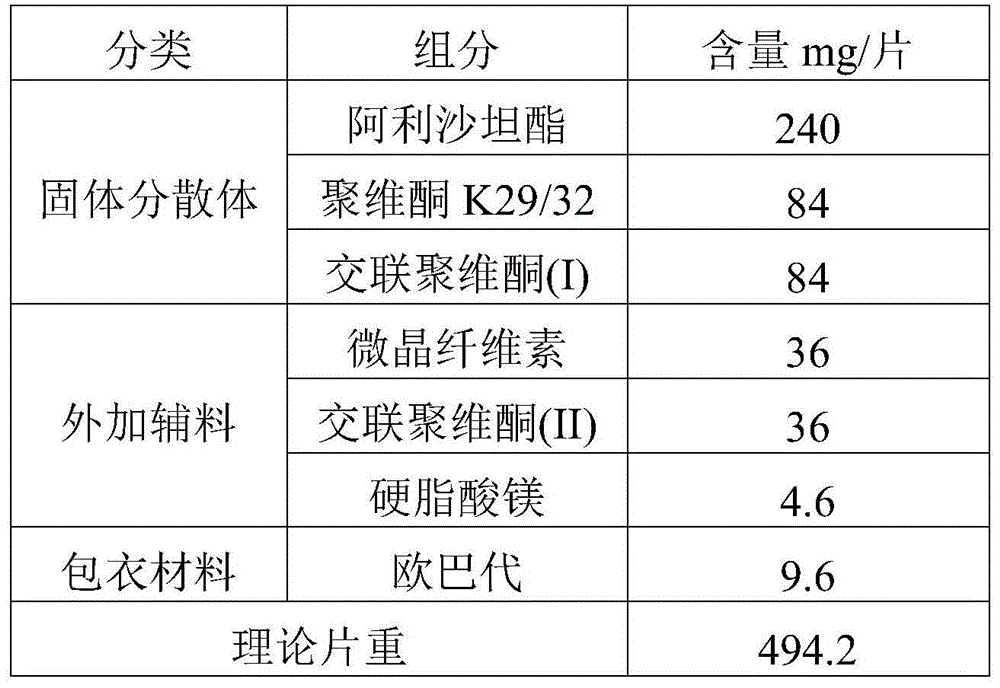

[0051] prescription:

[0052]

[0053] preparation:

[0054] 1. Preparation of solid dispersion

[0055] Dissolve the medicine and Povidone K29 / 32 in an appropriate amount of dichloromethane-ethanol mixed solution, add cross-linked Povidone (I) in the fluidized bed, and spray the prepared solution into the fluidized bed with a spray gun. In-bed granulation and drying to obtain a solid dispersion of allisartan medoxomil; further XRD experiments found that the active ingredient of allisartan medoxomil was highly dispersed in the solid dispersion, proving that the preparation effect of the solid dispersion reached expectations.

[0056] 2. Preparation of pharmaceutical composition

[0057] The solid dispersion is uniformly mixed with other materials, pressed into tablets to obtain plain tablets, and film-coated to obtain the alisartan medoxomil pharmaceutical composition.

Embodiment 3

[0059] prescription:

[0060]

[0061]

[0062] preparation:

[0063] 1. Preparation of solid dispersion

[0064] Medicine and povidone K29 / 32 are dissolved in an appropriate amount of dichloromethane-ethanol mixed solution, microcrystalline cellulose and crosslinked povidone (I) are added in the fluidized bed, and the prepared solution is top-sprayed with a spray gun The method was sprayed into a fluidized bed to granulate, and dried to obtain a solid dispersion of alisartan medoxomil; further XRD experiments found that the active ingredient of alisartan medoxomil was highly dispersed in the solid dispersion, which proved that the preparation effect of the solid dispersion reached the expectation.

[0065] 2. Preparation of pharmaceutical composition

[0066] The solid dispersion is uniformly mixed with other materials, pressed into tablets to obtain plain tablets, and film-coated to obtain the alisartan medoxomil pharmaceutical composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com