Device and method for removing organic sulfur in yellow phosphorus tail gas

A technology for yellow phosphorus tail gas and organic sulfur, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve problems such as no effective methods, achieve the effect of reducing implementation costs, reducing processing costs, and facilitating follow-up processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

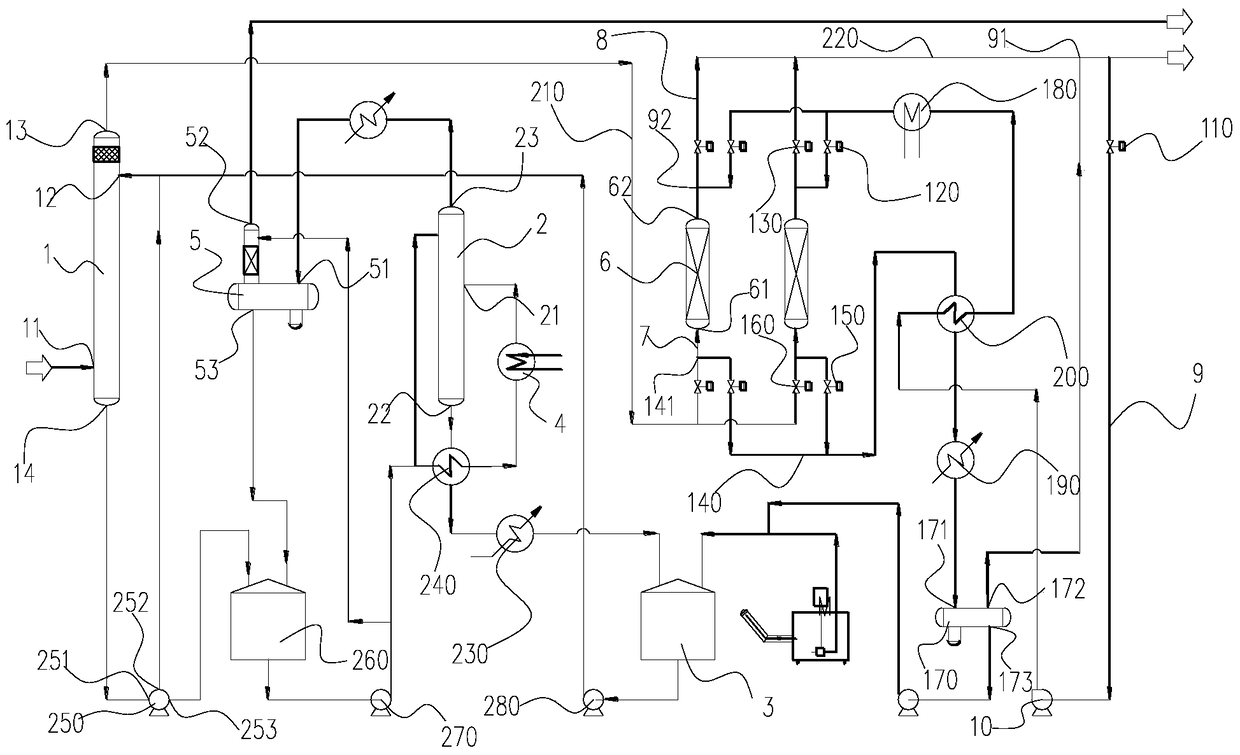

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] Such as figure 1 As shown, the device for removing organic sulfur in the yellow phosphorus tail gas of the present invention includes an oil washing tower 1, a regeneration tower 2 and a lean oil storage tank 3, and the oil washing tower 1 is provided with a tail gas inlet 11, a lean oil inlet 12, Tail gas outlet 13 and oil-rich outlet 14. The regeneration tower 2 is provided with a rich-oil inlet 21, a lean-oil outlet 22 and an organic sulfur outlet 23. The lean-oil inlet 12 communicates with the lean-oil storage tank 3 through pipelines. The oil outlet 14 communicates with the rich oil inlet 21 through a pipeline, and the lean oil outlet 22 communicates with the lean oil storage tank 3 through a pipeline.

[0032] The oil scrubber 1 can adopt a general absorption tower. In order to make the yellow phosphorus tail gas fully contact with the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com