A Membrane Separation and Concentration System for Removing Heavy Metals in Waste Incineration Fly Ash

A technology of waste incineration fly ash and concentration system, which is applied in the removal of solid waste and other directions, can solve the problem of cross-contamination between fly ash and heavy metals, and achieves the effect of solving the cross-contamination of fly ash and heavy metals, saving investment, and having a high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

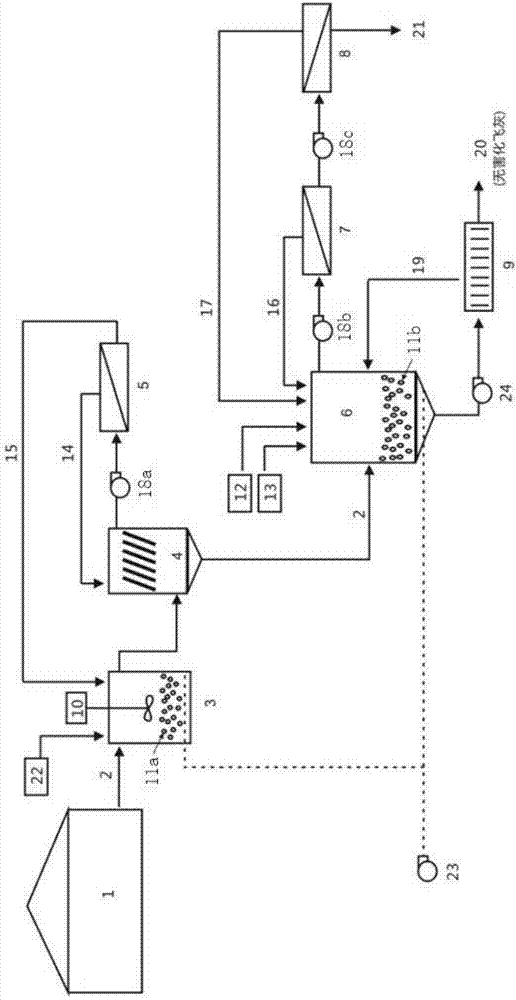

[0029] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0030] As shown in the drawings, the present invention includes: cleaning tank 3, sedimentation tank 4, extraction tank 6 and filter press 9, the fly ash inlet of cleaning tank 3 is connected to the fly ash outlet of waste incineration workshop 1 through pipelines, cleaning tank 3 A tap water inlet is provided on the top, and a stirring device 10 and a fine aeration system 11a are arranged in the cleaning tank 3. The supernatant liquid outlet of the cleaning tank 3 is connected to the fly ash inlet of the sedimentation tank 4, and the supernatant liquid outlet of the sedimentation tank 4 passes through Raw water pump one 18a is connected to the inlet of the primary membrane filtration system 5, the outlet of the reflux liquid of the primary membrane filtration system 5 is connected to the return port of the sedimentation tank 4 through a pipeline, and the permeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com