A Welding Method for Steam Turbine Blow-Assembled Diaphragm Cascade

A welding method and steam turbine technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as difficulty in controlling the deformation of the diaphragm cascade, uneven heating, inconsistent thermal expansion and contraction, and reduce mutual influence. , reduce stress and deformation, increase the effect of structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

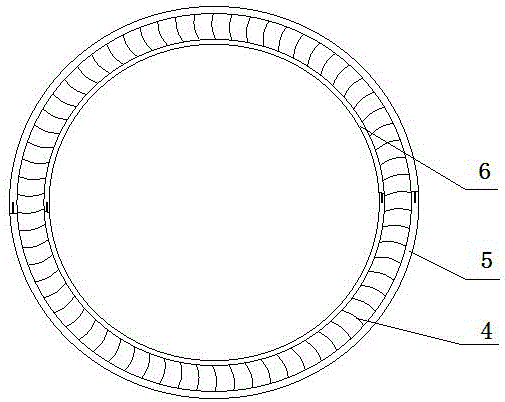

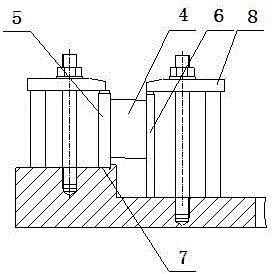

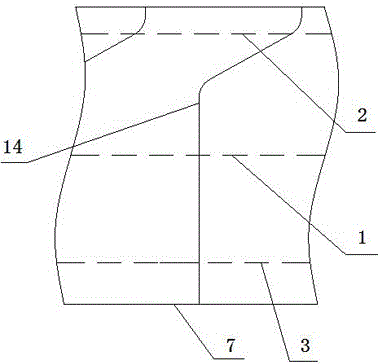

[0026] Such as Figure 1 to Figure 4 As shown in the figure, a welding method for steam turbine blow-fit diaphragm cascades includes two steps A and B: before step A is carried out, use a fixed pressing device 8 to press each stator blade 4 through the outer crown 5 and the inner crown 6 Tight, the inlet side 7 of the stator blade is downward. Argon arc welding is used for welding.

[0027] A. In order to increase the rigidity and dimensional stability of the clapboard cascade welding, the positioning welding of the stator blade 4 is performed manually, and the positioning welding position and sequence are as follows:

[0028] (1) Spot welding the first welding position 1 located at the center of both ends of the stator blade 4 can reduce the eccentricity of the centroid of the stator blade 4 and improve the dimensional stability;

[0029] (2) There is an inflection point in the structure of the second welding position, which is prone to stress concentration, and because thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com