Cavitation repair method for blades of water turbine

A blade cavitation and repair method technology, applied in the field of remanufacturing, can solve the problems of reducing blade strength, increasing repair workload, large blade deformation, etc., to achieve the effect of increasing service life and reducing repair workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

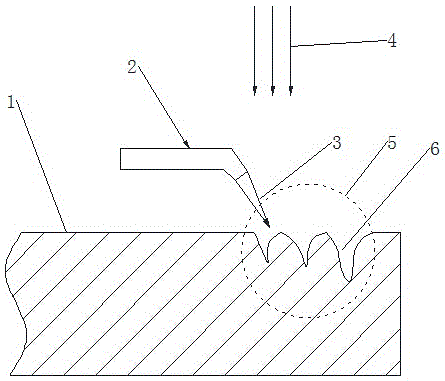

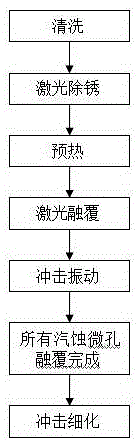

[0013] Such as figure 1 , 2 Shown, a kind of water turbine blade cavitation repairing method of the present invention comprises the following steps:

[0014] (1) Cleaning: Use an organic solvent to clean the blade 1 to be repaired, and remove the oil stain on the cavitation part of the blade 1 to be repaired;

[0015] (2) Rust removal: irradiate the cavitation area 5 with a high-power short-pulse laser beam 4 to vaporize and evaporate the metal oxide layer on the surface of the blade 1 until the body material of the blade 1 is exposed;

[0016] (3) Preheating: irradiate the part to be repaired with a high-power short-pulse laser beam, so that the material of the blade body that is about to be laser-melted will be melted in a shallow layer;

[0017] (4) Laser cladding: The cladding laser head sprays and fills the cladding metal powder to the preheated cavitation part, and emits a laser beam to irradiate the metal powder to fuse the cladding material and the blade body materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com