Refining method and system for preparing polymerization-grade propylene from refinery crude propylene

A technology of polymerization grade propylene and refining method, which is applied in the field of refining system, which can solve the problems of low adsorption performance, periodic catalyst regeneration, high energy consumption, etc., and achieve the effects of low annual average cost, long service life and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

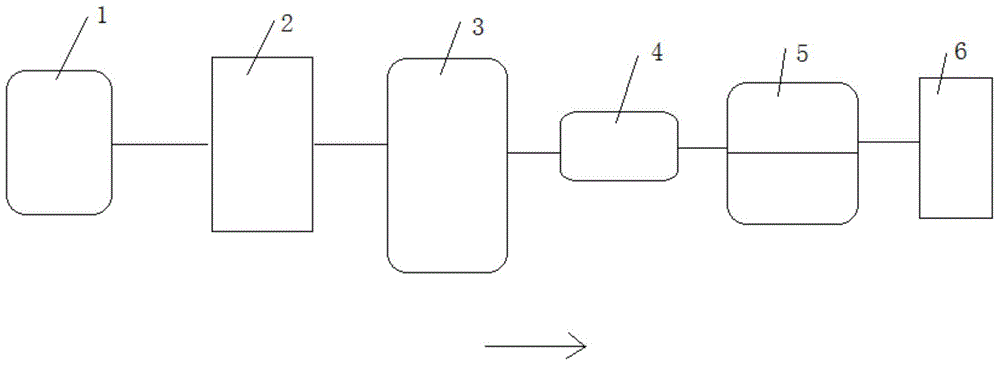

Image

Examples

Embodiment Construction

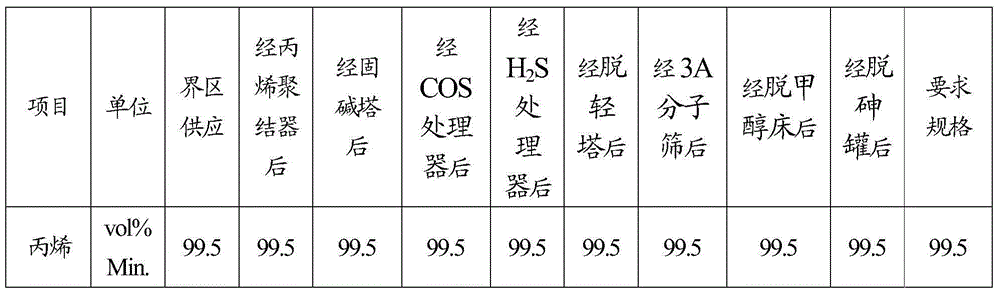

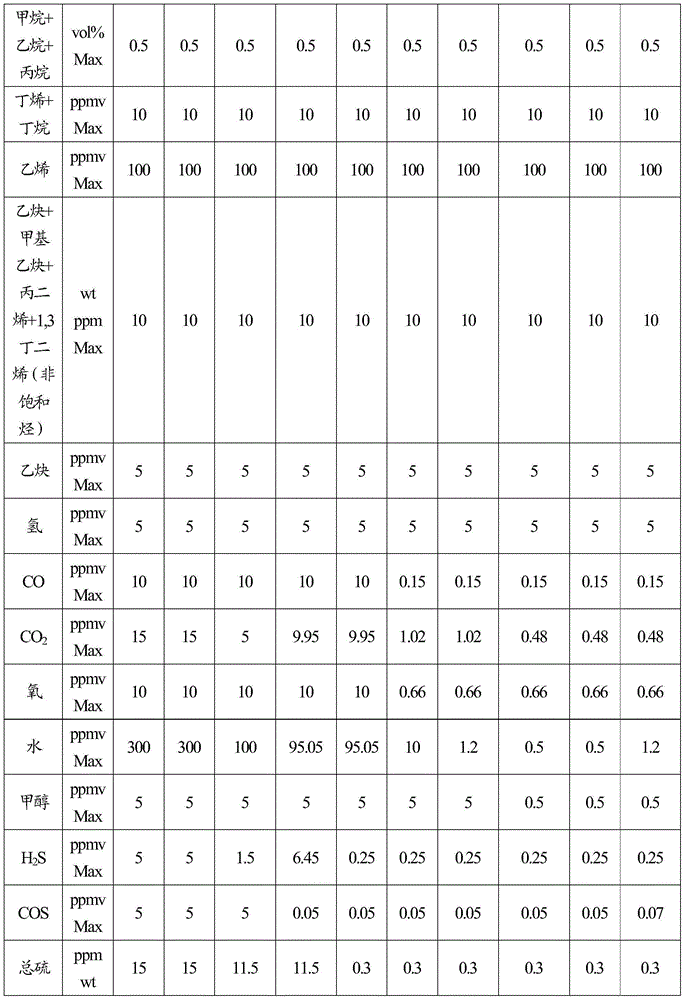

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below through specific examples.

[0038] A large number of small molecular gaseous substances will be produced in the process of petroleum refining, which contains H 2 、CH 4 、C 2 h 4 、C 2 h 6 、C 3 h 6 、C 3 h 8 After simple gas separation, crude propylene can be obtained. An oil refinery with a processing capacity of 10 million tons of crude oil per year can produce about 200,000 to 250,000 tons of propylene per year. Generally, the composition of the crude propylene material obtained after separation in the refinery gas separation unit is as follows:

[0039] project

unit

Boundary Supply

Acrylic

vol%Min.

99.5

vol%Max

0.5

ppmv Max

10

Vinyl

ppmv Max

100

Acetylene+met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com