A method for the selective reduction of aromatic nitro compounds to prepare aromatic amines when iron oxide/Fe(ii) coexists

An aromatic nitro, iron oxide technology, applied in the preparation of amino compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of reducing production costs, environmental pollution, etc., and achieves cost reduction, high reduction selectivity, and reaction mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

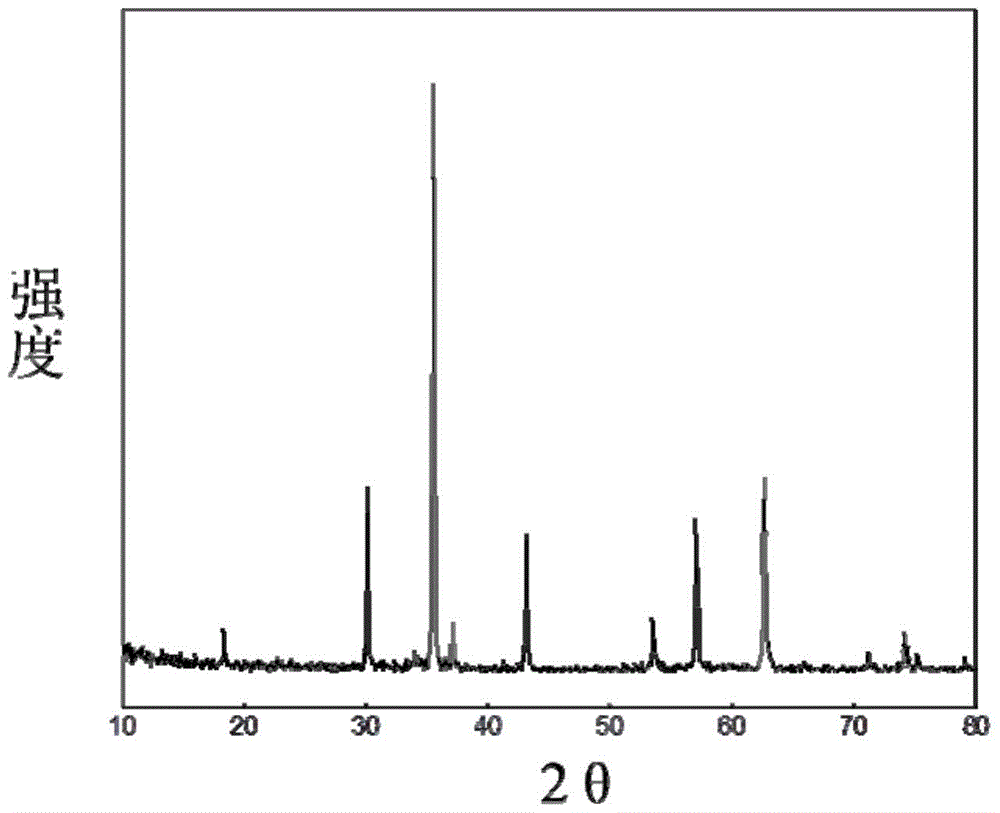

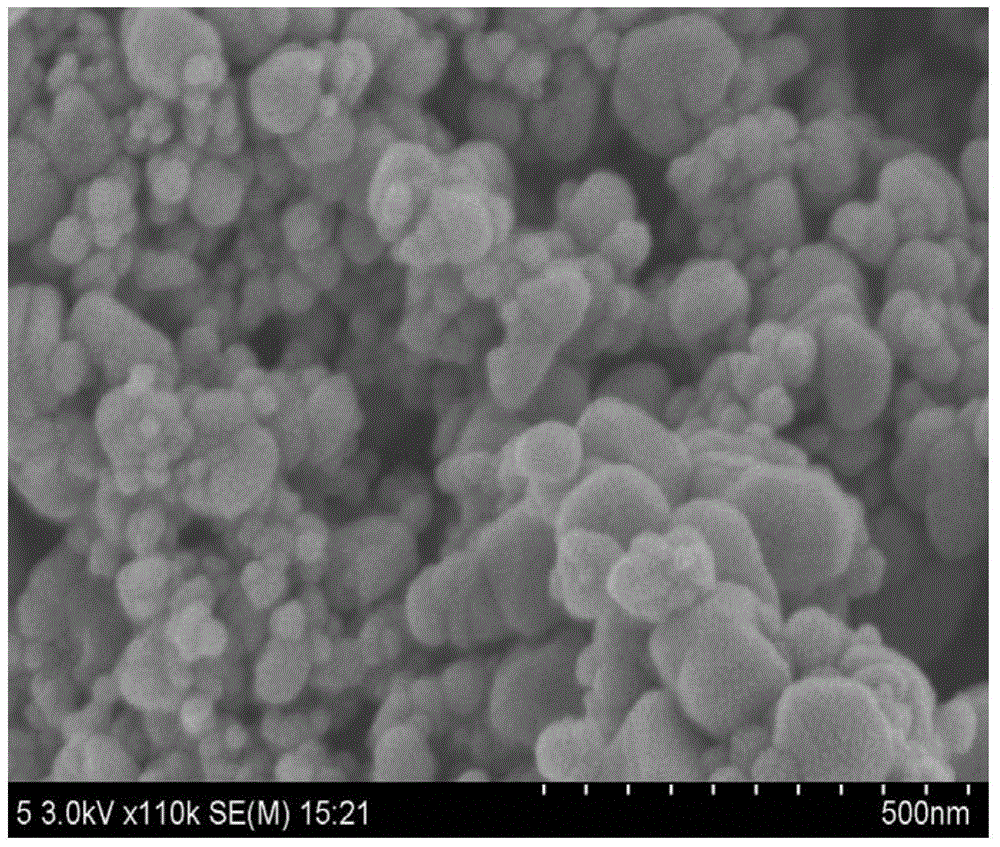

[0011] The present invention relates to a method for reducing aromatic nitro groups to aromatic amino groups as shown below,

[0013] Among them, Aryl is an aromatic group, and the method uses iron oxide as a catalyst and divalent iron as a reducing agent.

[0014] More specifically, in the aforementioned method, wherein the aromatic group is C 6 -C 10 Aryl.

[0015] More specifically, in the aforementioned method, wherein the aromatic group is selected from phenyl or naphthyl.

[0016] More specifically, in the foregoing method, wherein the aromatic group is optionally selected by one or more R groups independently selected from electron withdrawing groups or electron donating groups 1 Group substituted.

[0017] More specifically, in the aforementioned method, wherein the R 1 Selected from C 1-6 Alkyl, C 1-6 Alkoxy, cyano, hydroxyl, halogen, -SO 3 H, -COOH (list a series of groups).

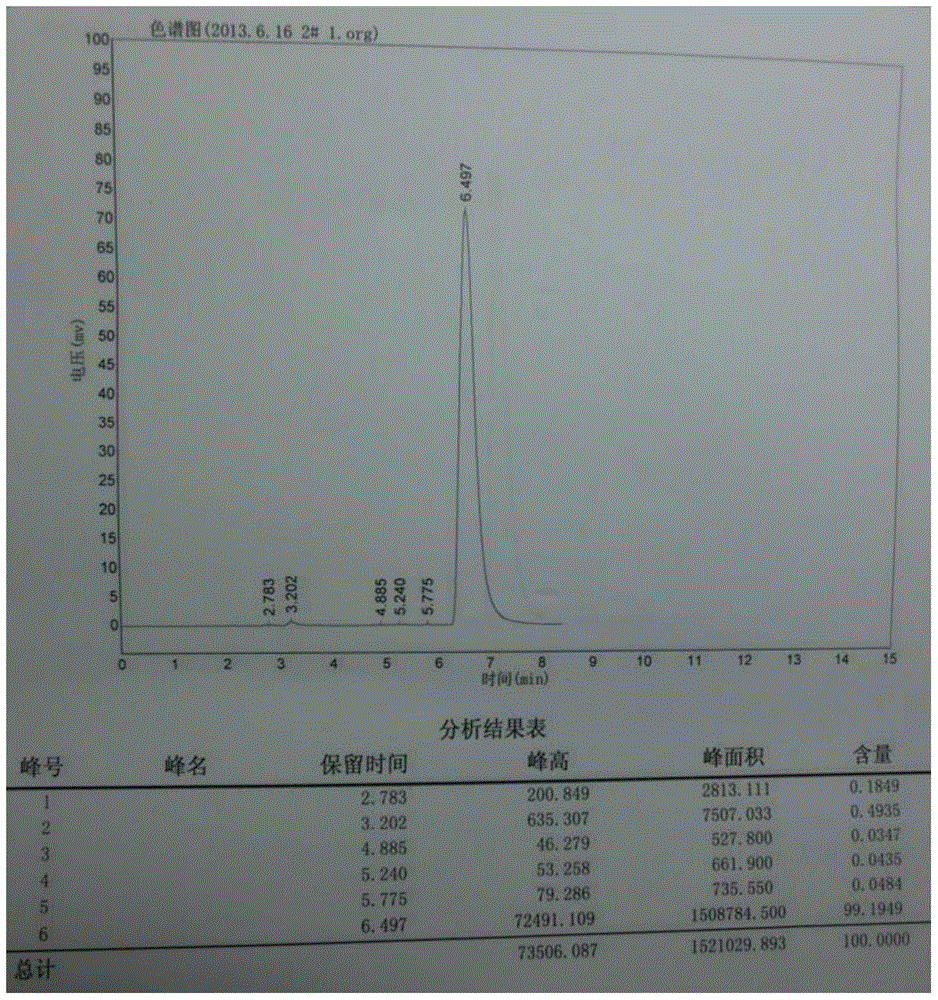

[0018] The present invention also relates to a method for preparing 4,4'-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com