Polyisoprene preparation method

A technology for polyisoprene and polymerization, which is applied in chemical instruments and methods, mixers with rotary stirring devices, dissolution, etc. The product "hangs on the wall" and other problems, to achieve the effect of improving the conversion rate, increasing the concentration of the feed monomer, and reducing the amount of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0050] This preparation example is used to illustrate the preparation of rare earth catalysts.

[0051] Prepare according to Example 1 of CN102108105A.

[0052] Starting from neodymium trioxide, using cyclohexane as a solvent, a neodymium naphthenate / cyclohexane solution is prepared by direct extraction method, wherein the concentration of Nd element is 0.21mol / l. Triisobutylaluminum and diethylaluminum chloride were respectively prepared into cyclohexane solutions with a concentration of 2 mol / l for future use. The water content in the solvent is lower than 20ppm, and the oxygen is exhausted with nitrogen before use, and the aging tank is dried and oxygen exhausted.

[0053] Under nitrogen protection, add 655ml hexanaphthene solution in 2L catalyst aging kettle, then add the neodymium naphthenate / hexanaphthene solution of 65ml isoprene (0.65mol) and 62ml in the aging kettle, again in Add 20ml of cyclohexane solution of diethylaluminum chloride into the aging kettle under st...

Embodiment 1

[0060] This example is used to illustrate the method for preparing polyisoprene of the present invention.

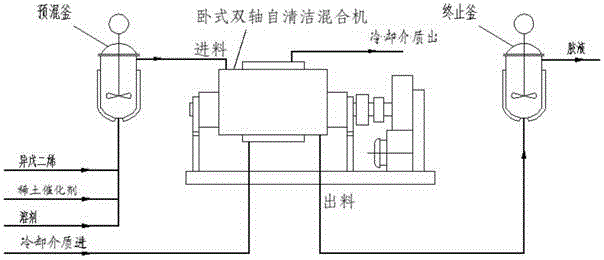

[0061] Under normal temperature and pressure, isoprene monomer (60.1kg / h, polymer grade, commercially available), cyclohexane (168.8kg / h, commercially available) and rare earth catalyst A (11.6kg / h, rare earth catalyst The molar ratio of the amount of A to the isoprene monomer is 1.2×10 -4 ), carry out premixing in the premixer, the time of premixing is 10min. Among them, the concentration of isoprene monomer was 25% by weight.

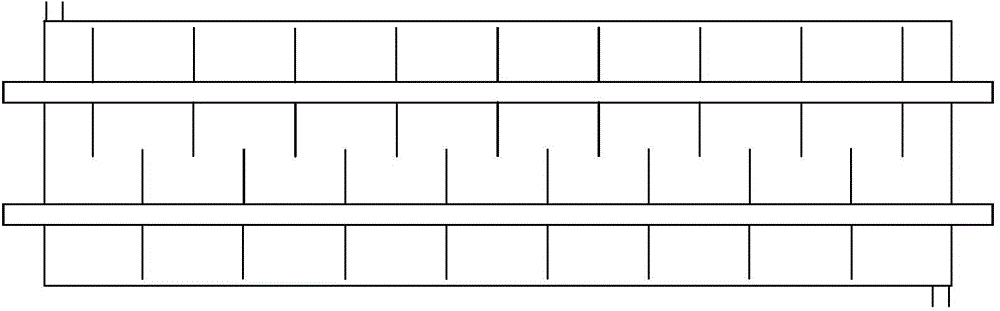

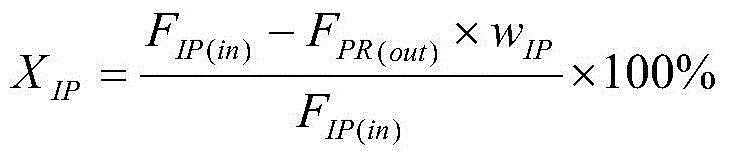

[0062] The reaction material formed after premixing is continuously fed into a horizontal twin-shaft self-cleaning mixer, the shell volume of which is 100L, and the amount of the reaction material is 60% by volume of the shell volume of the horizontal twin-shaft self-cleaning mixer, The average residence time of the reaction materials in the horizontal twin-shaft self-cleaning mixer is 10 minutes. The reaction temperature was controlled at a ...

Embodiment 2

[0065] This example is used to illustrate the method for preparing polyisoprene of the present invention.

[0066] Under normal temperature and pressure, isoprene monomer (72.1kg / h, polymer grade, commercially available), cyclohexane (154.5kg / h, commercially available) and rare earth catalyst A (13.9kg / h, rare earth catalyst The molar ratio of the amount of A to the isoprene monomer is 1.2×10 -4 ), premixed in the premixer, the premixing time is 10min. Among them, the concentration of isoprene monomer was 30% by weight.

[0067]The reaction material formed after premixing is continuously fed into a horizontal twin-shaft self-cleaning mixer, the shell volume of which is 100L, and the amount of the reaction material is 60% by volume of the shell volume of the horizontal twin-shaft self-cleaning mixer, The average residence time of the reaction materials in the horizontal twin-shaft self-cleaning mixer is 10 minutes. The reaction temperature was controlled at a constant temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com