Gel point control method in synthesis technology of polyester for powder coatings

A technology of synthesis process and control method, applied in the direction of powder coating, polyester coating, coating, etc., can solve the problems of loss, increase of production cost, damage of production equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

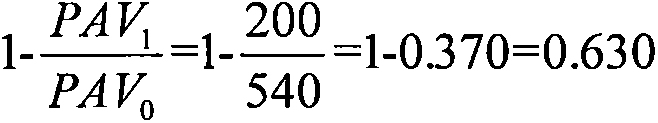

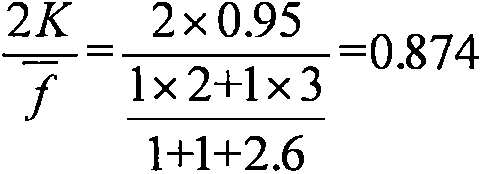

[0018] In the reaction vessel, add 1 mol of terephthalic acid (mole, amount of substance), 1 mol of trimellitic anhydride, 2.6 mol of ethylene glycol, a small amount of catalyst, mix well, take a sample of 0.7 g, and carry out the reaction with 0.1 mol / L potassium hydroxide ethanol solution Titration, test acid value according to national standard GB / T6743-2008, calculate PAV 0 It is 540±5mg / g, then heated to 130°C for esterification, then heated to 210°C, and polycondensed at a vacuum of 10kPa. After 3 hours, take a sample to measure the acid value, and calculate the PAV 1 It is 200±5mg / g. calculate:

[0019] 1 - PAV 1 PAV 0 = 1 - 200 540 = 1 - 0.370 = 0.630

[0020] 2 K ...

Embodiment 2

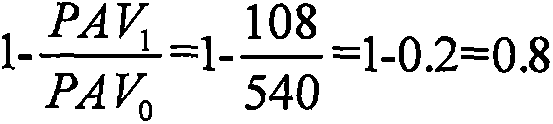

[0023] In the reaction vessel, add 1 mol of terephthalic acid (mole, amount of substance), 1 mol of trimellitic anhydride, 2.6 mol of ethylene glycol, a small amount of catalyst, mix well, take a sample of 0.7 g, and carry out the reaction with 0.1 mol / L potassium hydroxide ethanol solution Titration, test acid value according to national standard GB / T6743-2008, calculate PAV 0 It is 540±5mg / g, then heated to 140°C for esterification, then heated to 210°C, and polycondensed at a vacuum of 75kPa. After 3 hours, take a sample to measure the acid value, and calculate the PAV 1 It is 108±5mg / g. calculate:

[0024] 1 - PAV 1 PAV 0 = 1 - 108 540 = 1 - 0.2 = 0.8

[0025] 2 K ...

Embodiment 3

[0028] In the reaction vessel, add 1 mol of terephthalic acid (mole, amount of substance), 1 mol of trimellitic anhydride, 2.6 mol of ethylene glycol, a small amount of catalyst, mix well, take a sample of 0.7 g, and carry out the reaction with 0.1 mol / L potassium hydroxide ethanol solution Titration, test acid value according to national standard GB / T6743-2008, calculate PAV 0 It is 540±5mg / g, then heated to 140°C for esterification, then heated to 210°C, and polycondensed at a vacuum of 90kPa. After 2 hours, take a sample to measure the acid value, and calculate the PAV 1 It is 80±2mg / g. calculate:

[0029] 1 - PAV 1 PAV 0 = 1 - 80 540 = 1 - 0.148 = 0.852

[0030] 2 K ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com