Method for recycling copper, indium and gallium from waste copper-indium-gallium target

A technology of copper indium gallium and copper recovery, which is applied in the direction of improving process efficiency, etc., can solve the problems of large environmental pollution, complicated operation, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

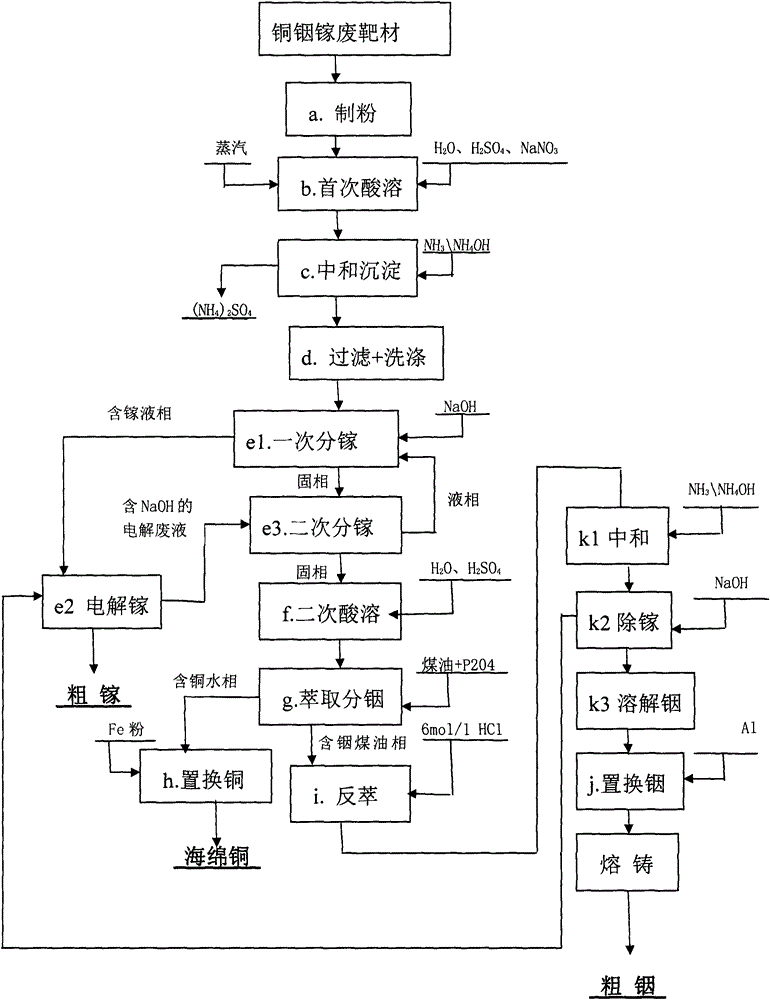

Image

Examples

Embodiment

[0049] The examples are merely illustrative and not restrictive.

[0050] Step a: Use a ball mill to grind the waste copper indium gallium target into powder with a particle size of about 90 mesh.

[0051] Step b: Mix the powder with water and 98% concentrated sulfuric acid, dissolve the powder under the action of the concentrated sulfuric acid dilution and exothermic heat, add nitric acid or nitrate solution in the later stage of dissolution and heat to above 95°C, continue the reaction until the powder completely dissolved. The weight ratio between CIG powder and concentrated sulfuric acid in this step is 1:2, and the weight ratio between CIG powder and water is 1:1. The above heating is carried out by passing industrial waste steam into the reactor jacket. After dissolution, copper, indium, and gallium are respectively in the form of ions, namely Cu 2+ , In 3+ , Ga 3+ The form exists in solution.

[0052] Step c: Add ammonia water to the mixture obtained in step b, and neutrali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com