Deplating method for magnetic control sputtering graphite carbon film

A technology of magnetron sputtering and graphitic carbon, which is applied in the field of surface treatment to achieve efficient removal, high practical value, and anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

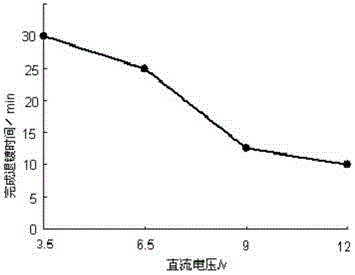

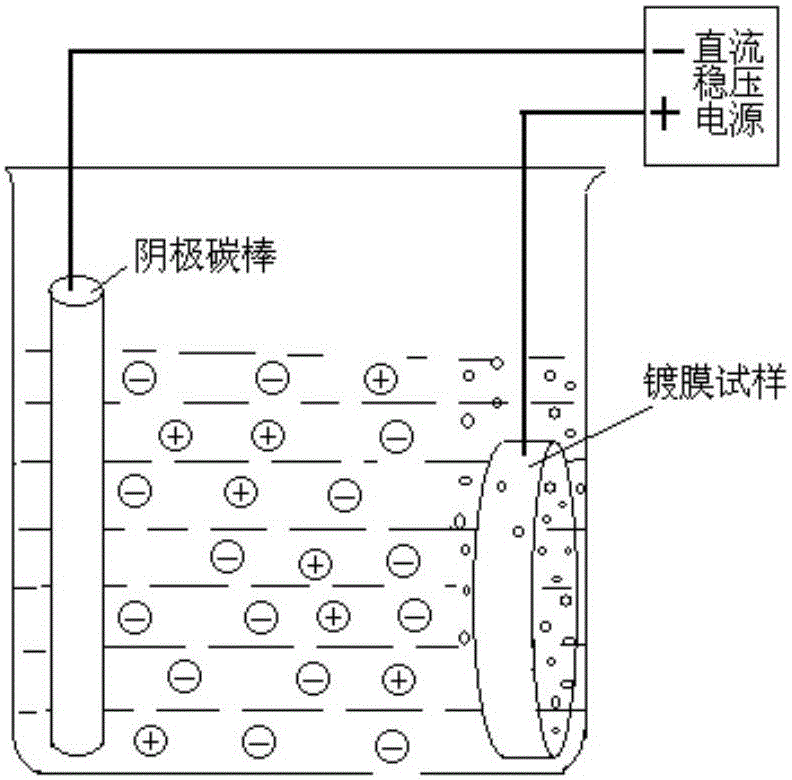

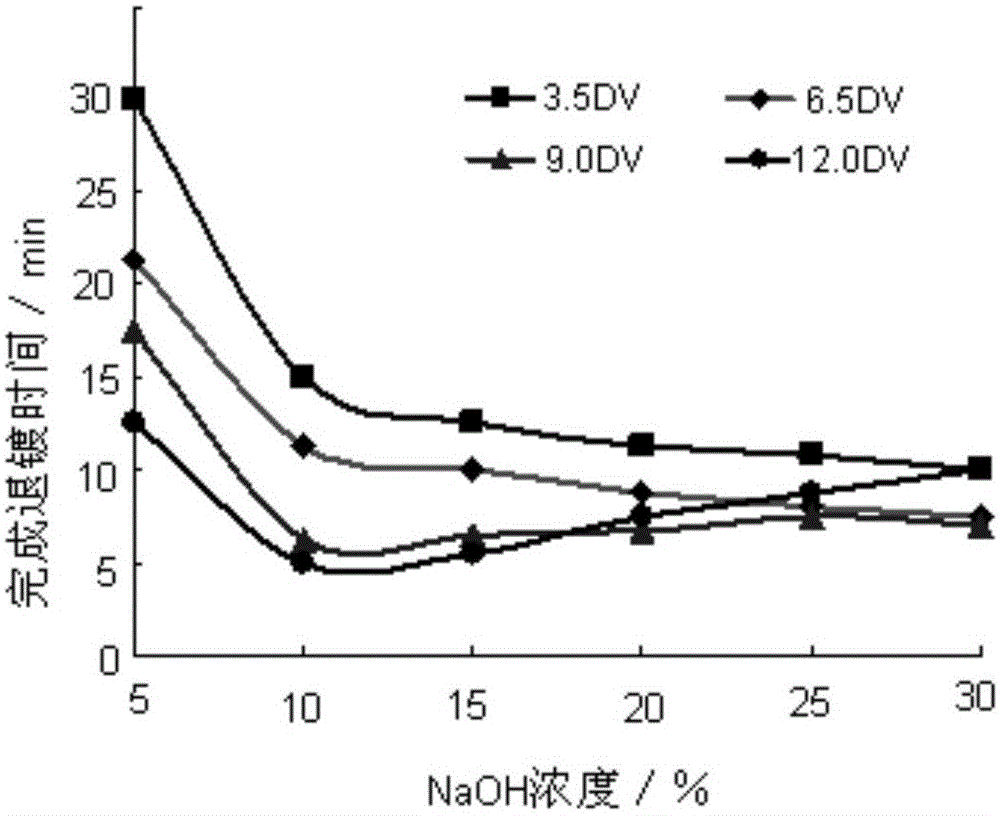

[0029] The substrate material is stainless steel, and the magnetron sputtering graphite carbon film test piece is used for deplating. Take 1L of distilled water, add 50g of alkali sodium hydroxide, 10g of sodium carbonate, stir evenly, and add surfactant dodecane to the above solution. Alcohol amide 10g, after stirring evenly, add 8g of anticorrosion complexing agent ammonium tripolyphosphonate and 2g of corrosion inhibitor adenosine diphosphonate, and immerse the substrate of the formed magnetron sputtering graphite-like carbon film in a 70°C In the deplating solution, and use the deplating solution as the electrolyte, electrolyze with a DC voltage of 9V, and the electrolysis time is 15 minutes. There is no coating on the surface and no damage to the base material.

Embodiment 2

[0031] Select the scrapped magnetron sputtering graphite carbon film gear as the test piece, the film thickness is 2-7um, take 1L of distilled water, add 100g of alkali sodium hydroxide, 10g of sodium carbonate, stir well, add surface active Agent lauryl alcohol amide 10g / l, after stirring evenly, add anticorrosion complexing agent ammonium tripolyphosphonate 8g and corrosion inhibitor adenosine diphosphonate 2g respectively, the substrate of the formed magnetron sputtering graphite-like carbon film Immerse in the deplating solution at 70°C, and use the deplating solution as the electrolyte, and perform electrolysis with a DC voltage of 9V. After the electrolysis time is 8 minutes, the deplating is completed. The deplating effect of this process is good, and the substrate is not damaged. Can be reused, saving costs.

Embodiment 3

[0033] The substrate material is stainless steel, and the magnetron sputtering graphite carbon film test piece is used for deplating. Take 1L of distilled water, add 100g of alkali sodium hydroxide, 10g of sodium carbonate, stir evenly, and add surfactant dodecane to the above solution. Alcohol amide 10g, after stirring evenly, add 8g of anticorrosion complexing agent ammonium tripolyphosphonate and corrosion inhibitor adenosine diphosphonate 2g respectively, and immerse the substrate of the formed magnetron sputtering graphite-like carbon film in a 70°C In the deplating solution, and use the deplating solution as the electrolyte, electrolyze with a DC voltage of 12V. After the electrolysis time is 6 minutes, the deplating is completed. The stainless steel test piece is taken out and cleaned. no damage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com