Preparation method of TiAl alloy quasi seed crystals

An alloy and seed crystal technology is applied in the field of preparation of TiAl alloy quasi-seed crystals, which can solve problems such as difficulty in obtaining TiAl alloy seed crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

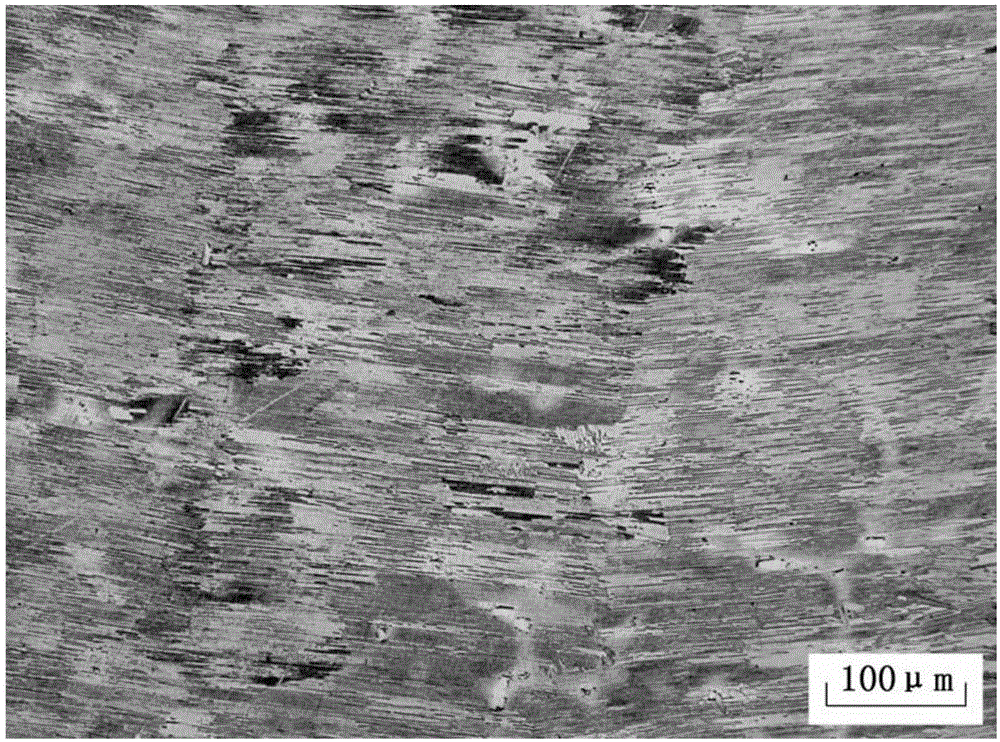

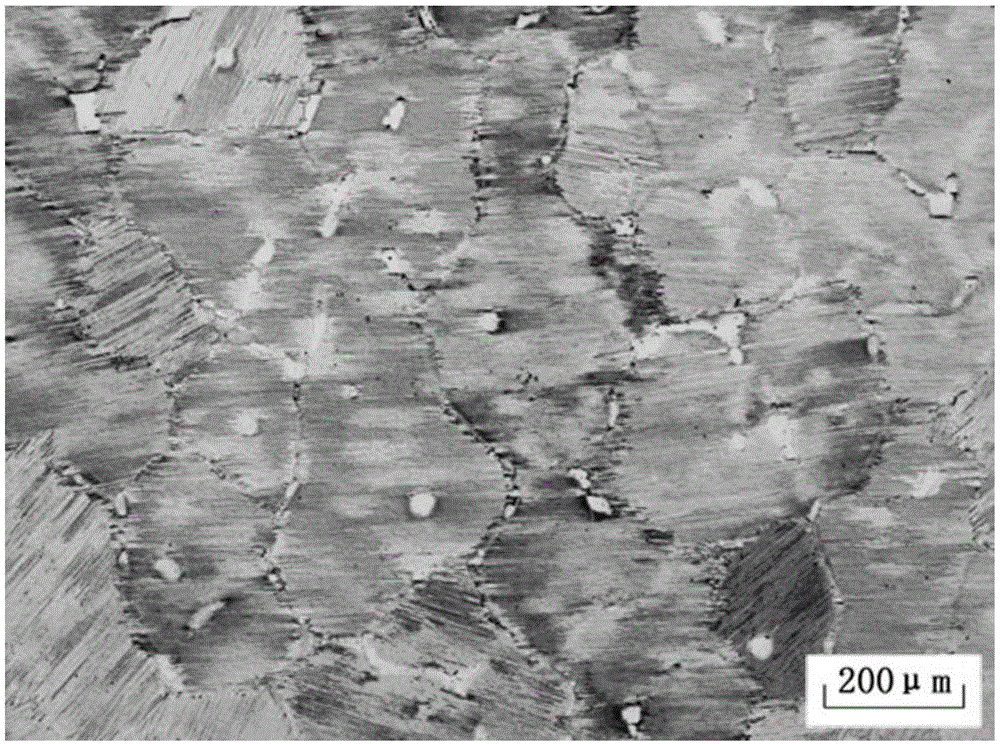

Image

Examples

preparation example Construction

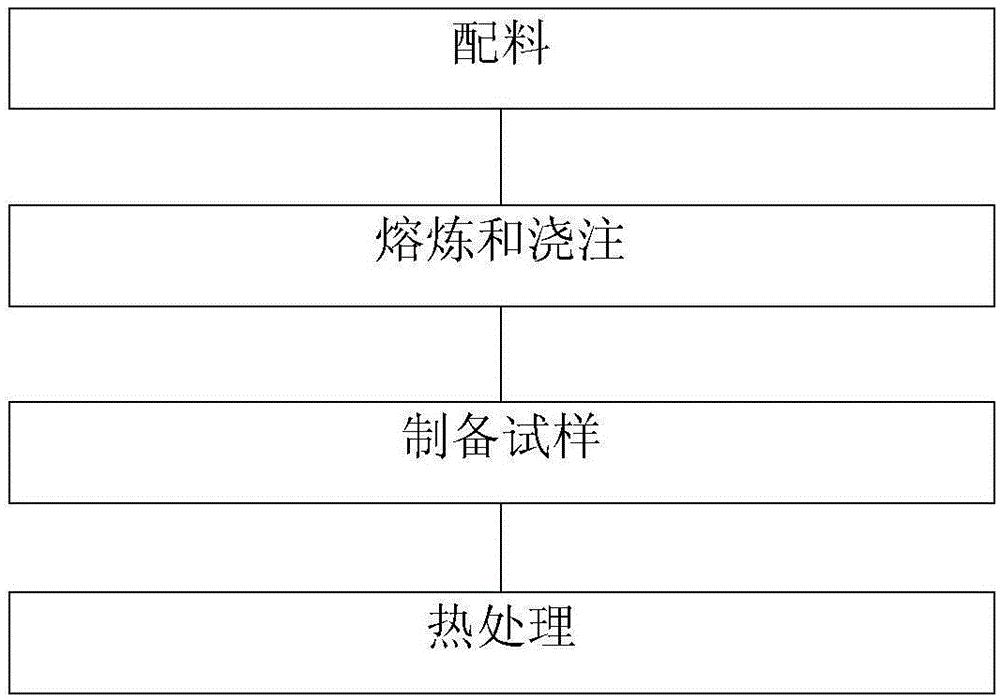

[0031] The invention is a method for preparing a TiAl alloy quasi-seed crystal. The implementation process of the present invention will be specifically described through 28 examples. Wherein the preparation process of each embodiment is the same, the difference lies in the process parameters in each embodiment, and the composition of the TiAl alloy involved, specifically see Table 1:

[0032] Table 1: Alloy composition and preparation parameters of each embodiment

[0033]

Embodiment 1

[0036] This example is a method for preparing Ti-48Al-2Nb-2Cr alloy quasi-seed crystal. Specific steps are as follows:

[0037]The first step, ingredients: according to the relationship between the mass fraction and the atomic fraction, prepare 1 kg of TiAl alloys with different atomic fractions shown in Table 1, and use a vacuum water-cooled copper crucible induction melting furnace to melt the Ti-48Al-2Nb-2Cr alloy The material is smelted.

[0038] The second step, smelting and pouring: put the prepared raw materials in a vacuum water-cooled copper crucible induction melting furnace, and use a conventional melting method for the first smelting. The melting temperature is 1650°C to 1750°C, and the temperature is kept for 5 minutes to obtain an alloy melt. After the heat preservation is completed, the power is turned off to cool the alloy melt to room temperature in a cold crucible to obtain an alloy ingot. Turn the cooled ingot over, put it back into the cold crucible, and ...

Embodiment 2

[0043] This example is a method for preparing Ti-48Al-2Nb-2Cr alloy quasi-seed crystal. Specific steps are as follows:

[0044] The first step, ingredients: according to the relationship between the mass fraction and the atomic fraction, prepare 1 kg of TiAl alloys with different atomic fractions shown in Table 1, and use a vacuum water-cooled copper crucible induction melting furnace to melt the Ti-48Al-2Nb-2Cr alloy The material is smelted.

[0045] The second step, smelting and pouring: put the prepared raw materials in a vacuum water-cooled copper crucible induction melting furnace, and use a conventional melting method for the first smelting. The melting temperature is 1650°C to 1750°C, and the temperature is kept for 5 minutes to obtain an alloy melt. After the heat preservation is completed, the power is turned off to cool the alloy melt to room temperature in a cold crucible to obtain an alloy ingot. Turn the cooled ingot over, put it back into the cold crucible, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com