Intelligent alarm triggering device for roller warp yarn breakage

A technology of intelligent alarm and triggering device, applied in the field of machinery, can solve the problems of parts prone to false alarms, affect the quality of finished products, affect the efficiency of the process, etc., and achieve the effects of easy assembly, improved adaptability, and improved integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

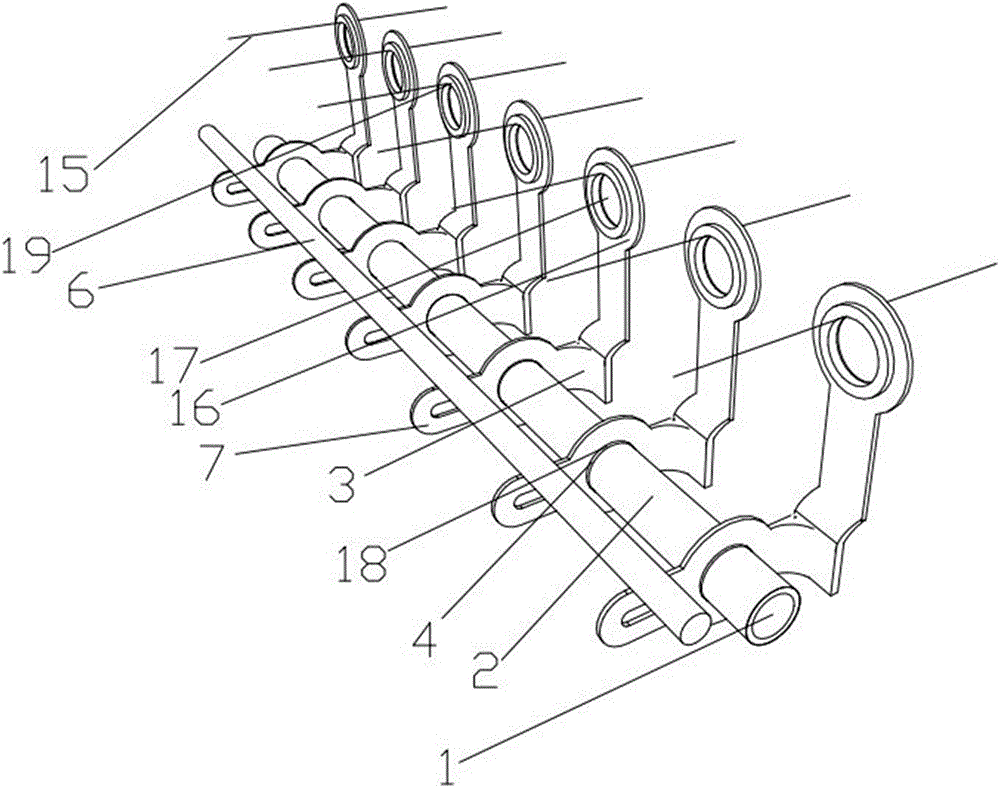

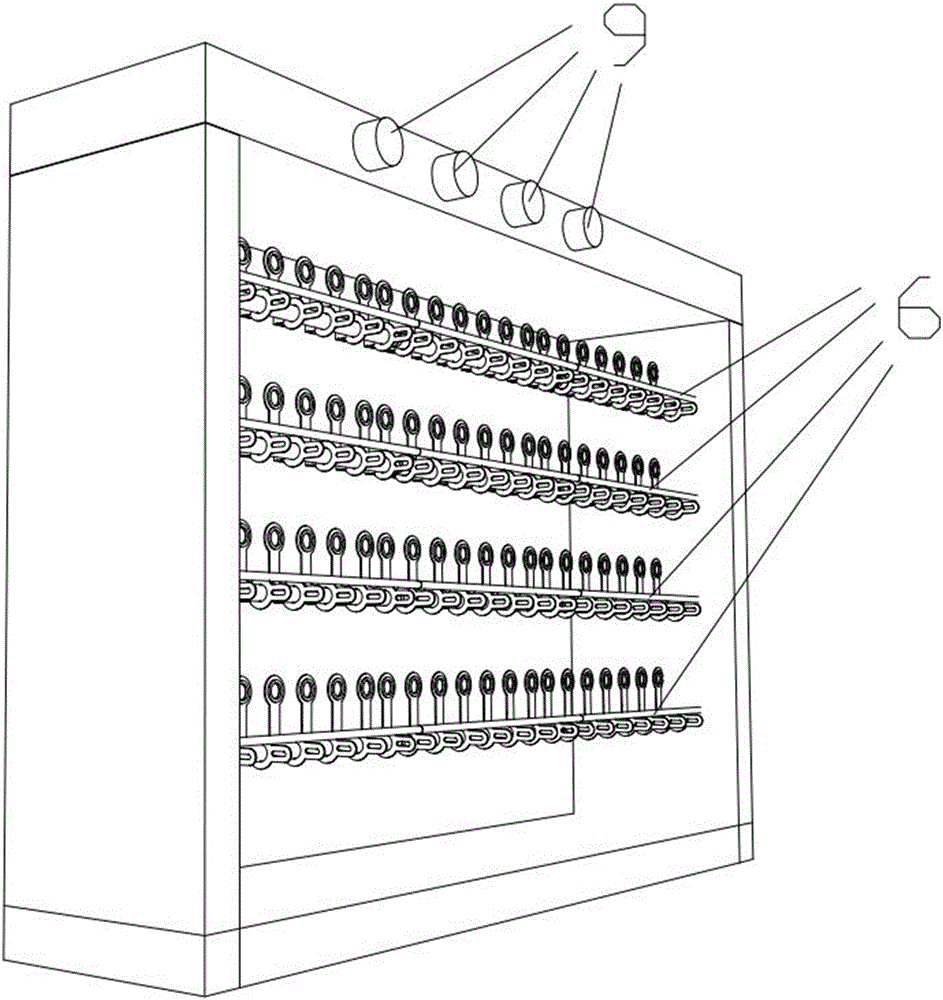

[0033] According to the number of wires that need to be detected by the device in the process, the operator takes the switch swing arm positioning sleeve 2 corresponding to the number, and puts the switch swing arm 3 on the constriction portion 4 of the sleeve 2, and then The switch swing arm locating sleeve 2 pierced with the switch swing arm 3 is sequentially sleeved on the center-through cross-bar 1 along the axis direction of the through-center cross-bar 1 .

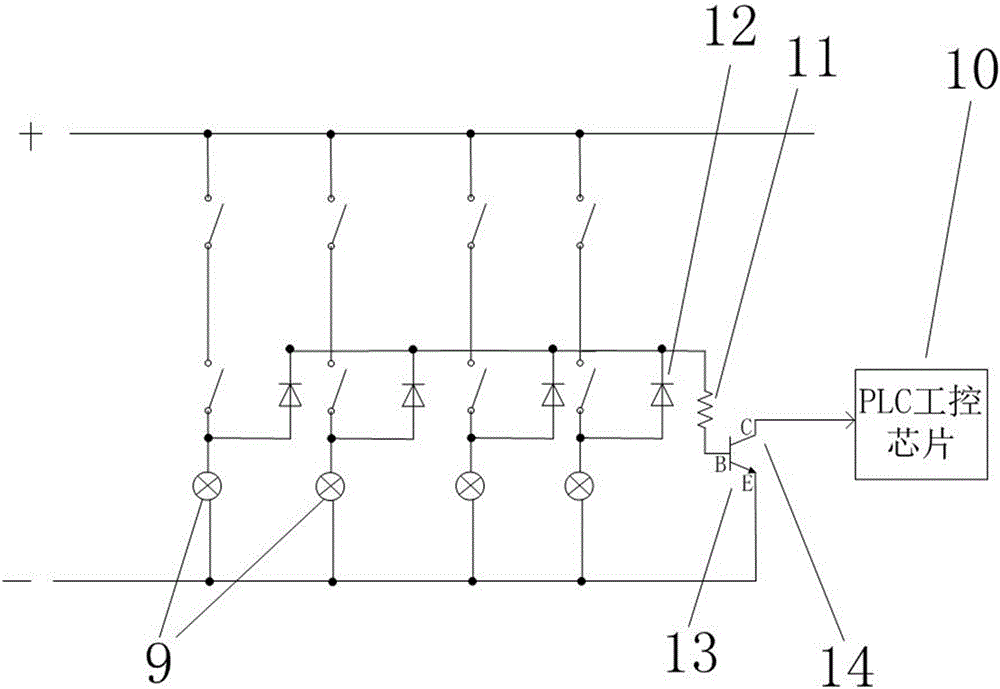

[0034] The operator puts the silk thread 15 through the thread hanging hole 5 of the switch swing arm 3, and only one thread can be inserted in each thread hanging hole 5, so that the switch swing arm 3 is pulled up by the thread to ensure that when the textile machine is working, The switch swing arm 3 can cooperate with the constriction portion 4 of the positioning sleeve 2 through the central hole 18 of the hinge part and rotate freely, and 24V direct current is connected to each cross bar 1 to complete the intelli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com