Production process for flame-retarding textile

A flame-retardant textile and production process technology, applied in the field of flame-retardant textile production process, can solve the problems of unknown washability, release of free formaldehyde, troublesome operation, etc., and achieve good cross-linking, excellent waterproof and flame-retardant performance, and good dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Pretreatment of textiles: Soak the cotton fabric to be treated in clear water, ultrasonic for 10 minutes, take it out, dry it at 80°C, and set it aside;

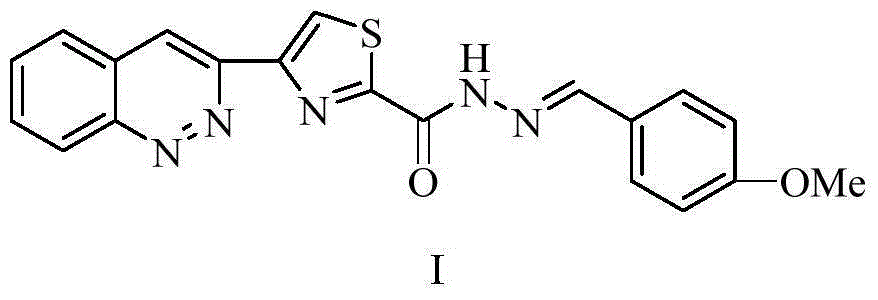

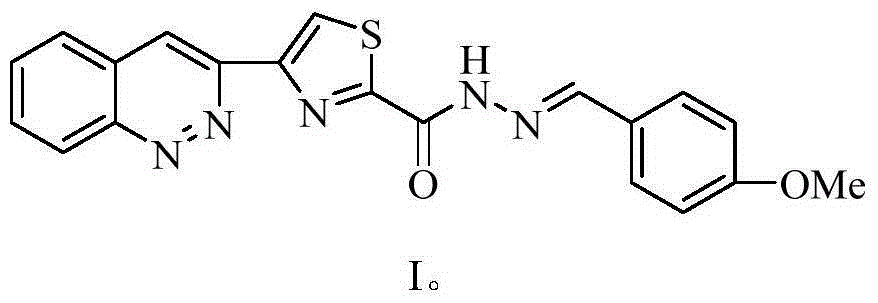

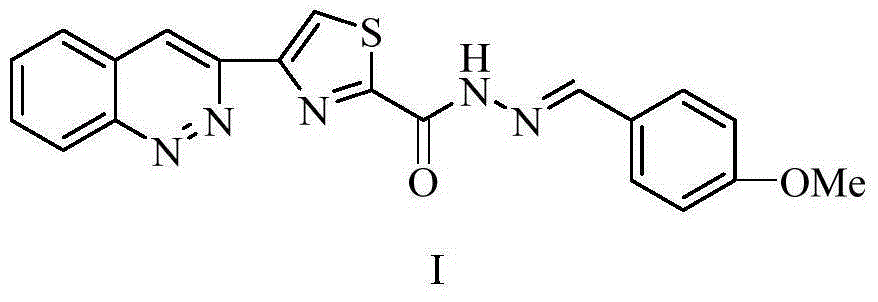

[0035] (2) Preparation of flame retardant finishing solution: add 0.05mol of the compound of formula I, 0.01mol of crosslinking agent N-methylolacrylamide, and 0.01mol of dispersant sodium lauryl sulfate into 100ml of ethanol, at 80°C Stirring and reacting for 1 hour to obtain a flame retardant finishing liquid;

[0036] (3) Flame-retardant finishing: soak the cotton fabric in the above-mentioned flame-retardant finishing solution for 20 minutes, then double-dip and double-roll, and the excess rate is 85%. Bake for 2 minutes;

[0037] (4) Dry after alkali washing and water washing.

Embodiment 2

[0039] (1) Pretreatment of textiles: soak the cotton fabric to be treated in clear water, ultrasonicate for 30 minutes, take it out, dry it at 80°C, and set it aside;

[0040] (2) Preparation of flame retardant finishing solution: add 0.1mol of the compound of formula I, 0.03mol of crosslinking agent N-methylolacrylamide, and 0.02mol of dispersant sodium lauryl sulfate into 200ml of acetone, at 80°C Stirring and reacting for 2 hours to obtain a flame retardant finishing solution;

[0041] (3) Flame-retardant finishing: soak the cotton fabric in the above-mentioned flame-retardant finishing solution for 20 minutes, then dip and roll twice, the excess rate is 95%, then dry the textile at 90°C for 10 minutes, and then bake it at 180°C 8 minutes;

[0042] (4) Dry after alkali washing and water washing.

Embodiment 3

[0044](1) Pretreatment of textiles: soak the cotton fabric to be treated in clear water, ultrasonicate for 20 minutes, take it out, dry it at 70°C, and set it aside;

[0045] (2) Preparation of flame retardant finishing liquid: add 0.08mol of formula I compound, 0.03mol of crosslinking agent N-methylolacrylamide, 0.02mol of dispersant sodium lauryl sulfate into 200ml of organic solvent, and heat at 80°C Under stirring reaction 2h, obtain flame retardant finishing solution;

[0046] (3) Flame-retardant finishing: soak the cotton fabric in the above-mentioned flame-retardant finishing solution for 20 minutes, then double-dip and double-roll, the excess rate is 90%, then dry the textile at 90°C for 10 minutes, and then bake it at 180°C 6 minutes;

[0047] (4) Dry after alkali washing and water washing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com