Oxygenation power generating windmill with vertical shaft

A vertical axis and windmill technology, applied in the field of energy-saving and environmental protection technology and equipment, can solve the problems of low energy utilization rate, inability to automatically adjust, poor oxygenation effect, etc., and achieve the effect of improving wind energy utilization rate, improving water body, and eliminating black and odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

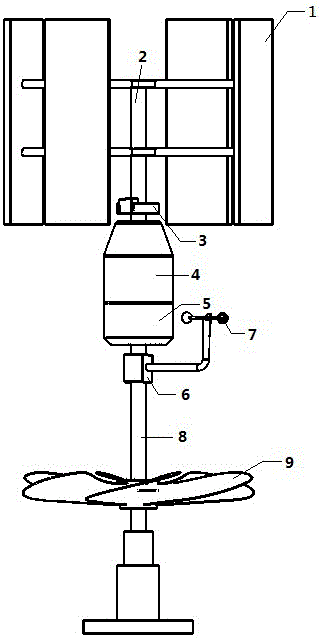

[0015] Such as figure 1 As shown, the vertical-axis oxygen-increasing windmill includes vertical-axis windmill blades (1), vertical central axis (2), braking system (3), generator (4), battery (5), controller ( 6), the sensor system (7), the aeration transmission mechanism (8), the vertical axis aeration impeller (9), the vertical axis windmill blade is connected with the aeration transmission mechanism and the generator through the central axis, and the aeration transmission mechanism It is connected with the aeration impeller, the central axis of the aeration impeller is arranged vertically, and the generator is connected with the storage battery, the braking system, the controller and the sensing system.

[0016] The windmill for generating electricity by increasing oxygen and controlling water in this embodiment utilizes the principle of aerodynamics and is composed of 4 vertical blades connected with a central shaft. The windmill can be started when the wind is light, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com