A moems vector hydrophone

A technology of vector hydrophone and optical fiber collimator, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of low signal-to-noise ratio of hydrophones, susceptibility to electromagnetic interference, signal interference, etc. Achieve the effect of low signal attenuation, small overall size, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

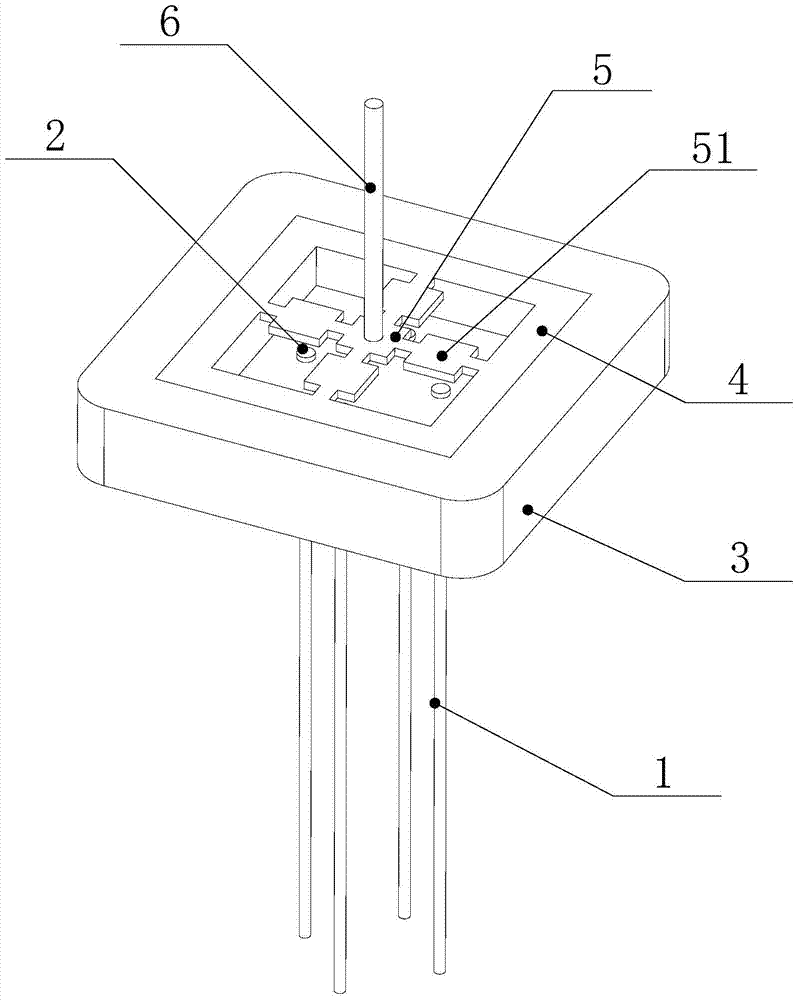

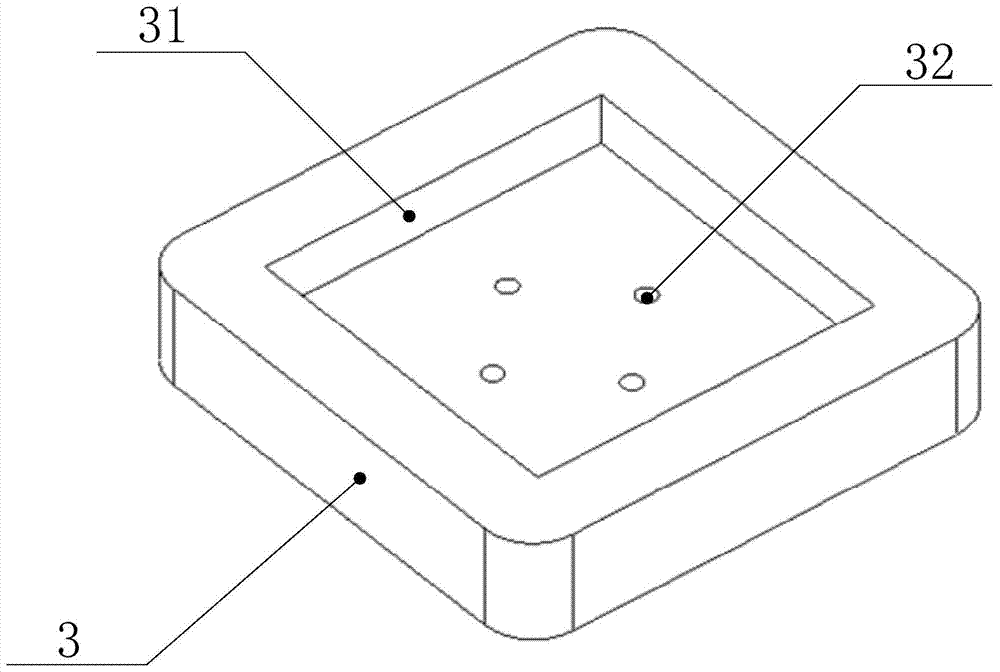

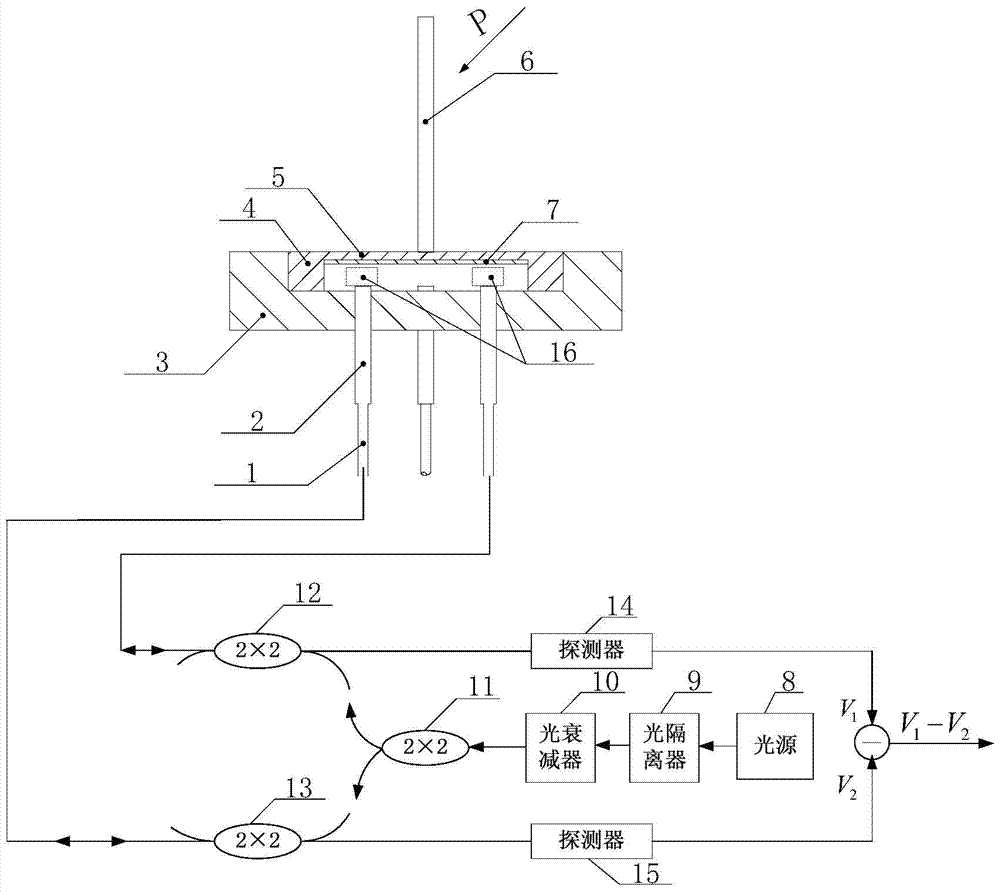

[0016] A kind of MOEMS vector hydrophone, comprising: optical fiber 1, optical fiber collimator 2, base 3, silicon-based frame 4, cantilever beam 5 and miniature cylinder 6; figure 1 As shown, the silicon-based frame 4 is a square frame structure, and a cantilever beam 5 is erected in the center; the cantilever beam 5 is a cross-shaped structure, and platforms 51 are respectively provided at the midpoints of the four sides of the word "ten" and at the intersection of the word "ten", and the platforms 51 are square. , the back of the platform 51 is coated with a reflective film 7 with a reflectivity not lower than 95%; the base 3 is a square structure, such as figure 2 As shown, there is a mounting groove 31 whose size matches the outer contour of the silicon-based frame 4 in the center, and the center position of the platform 51 on the four sides of the "ten" character of the cantilever beam 5 is provided with a mounting hole 32 corresponding to the corresponding position in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com