Subsurface measurement device and method based on total internal reflection and optical coherence tomography

A technology of optical coherence tomography and total internal reflection, which is applied in the field of subsurface measurement devices based on total reflection and optical coherence tomography, can solve problems such as low precision, damaged components, and small detection range, so as to improve measurement accuracy , Improve the detection speed and enhance the effect of three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

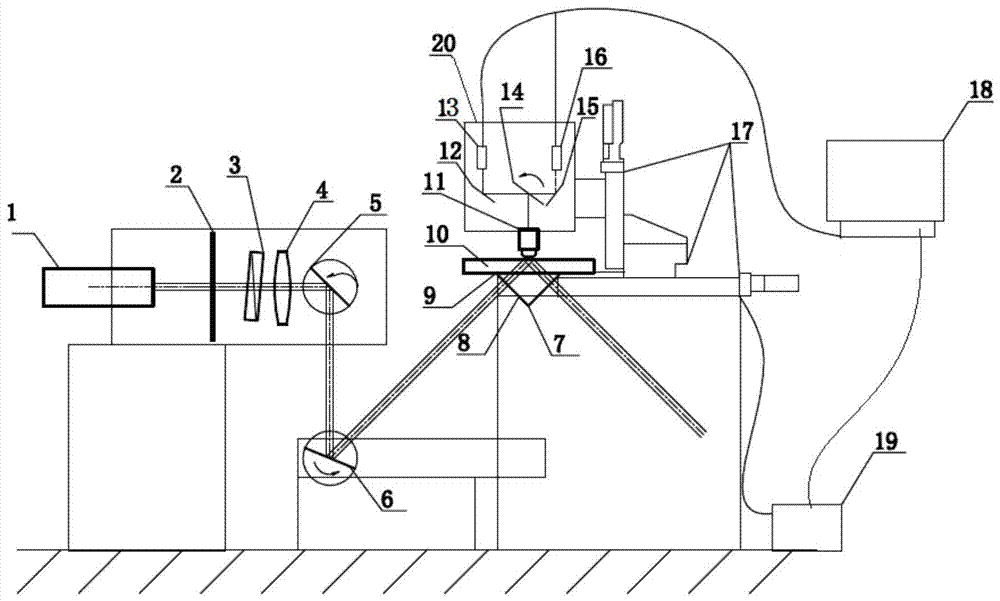

[0029] This embodiment describes in detail the structure of the multi-dimensional precision electronic control adjustment system in conjunction with the accompanying drawings.

[0030] combine Figure 5 , the three-dimensional micro-displacement part 17 in the multi-dimensional precision electronic control adjustment system of the device of the present invention is a horizontal bar structure formed by two parallel supports and a crossbeam, and the crossbeam can move up and down along the two parallel supports; the two parallel supports are arranged on the supporting platform 8, the microscope system bracket 20 is arranged on the beam, so that the x-axis is parallel to the beam, the y-axis is parallel to the plane of the support table 8, and the z-axis is parallel to the two parallel supports; track, two parallel supports move along the track in the y-axis direction; a track is provided on the beam, and the microsystem support 20 moves along the beam, that is, the track in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com