Xylan hyamine nanometer magnetic particle and preparing method thereof

A nano-magnetic and xylan technology, which is applied to the magnetism of organic materials/organic magnetic materials, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve problems such as magnetic functional materials that have not been reported, and achieve good industrial applications The effect of prospect, easy access to raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

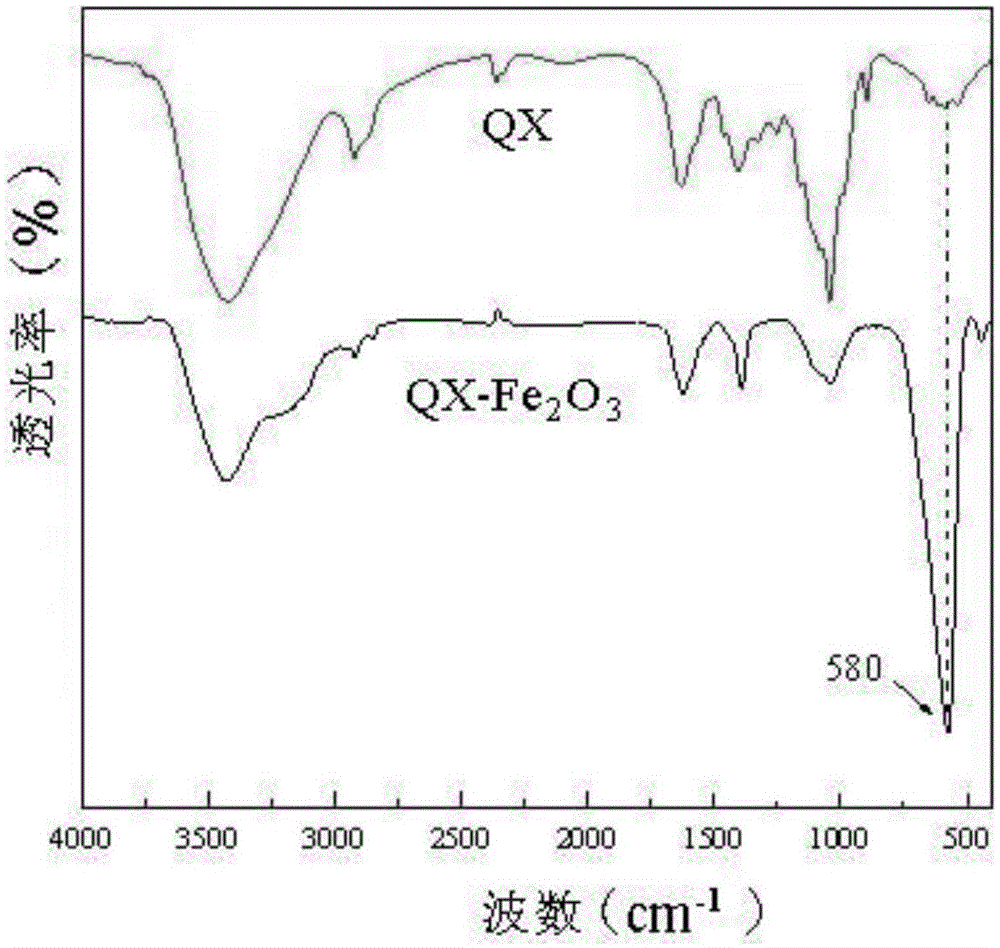

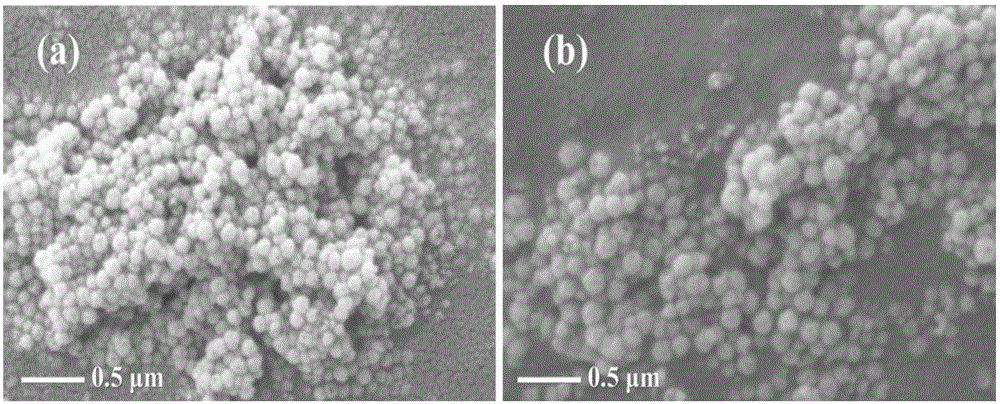

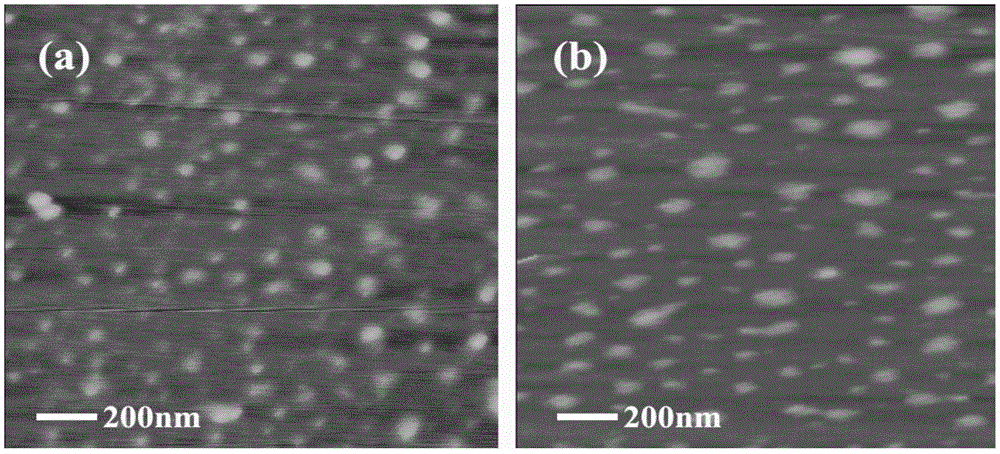

[0039] (1) Magnetic microspheres (γ-Fe 2 o 3 ) preparation: under magnetic stirring, 2.70g of FeCl 3 . 6H 2O was dissolved in 100mL of ethylene glycol, and dissolved for 0.5h to obtain a yellow transparent solution, then 7.20g of anhydrous sodium acetate was added to the solution, and the stirring was continued for 0.5h, after which the solution was transferred to a stainless steel autoclave, sealed and heated at 200°C Heating and reacting for 8 hours, cooling to room temperature after the reaction was over, to obtain black magnetic powdery solid particles, washing the solid particles three times with ethanol and water respectively, and finally drying them under vacuum at 60°C for 12 hours to obtain magnetic microspheres (γ-Fe 2 o 3 );

[0040] (2) Preparation of xylan quaternary ammonium salt (QX): Place 0.33g xylan in a three-necked flask, add 10mL of anhydrous DMSO, and dissolve in an oil bath at 95°C for 1.5h under stirring conditions to obtain light The yellow solut...

Embodiment 2

[0047] (1) Magnetic microspheres (γ-Fe 2 o 3 ) preparation: under magnetic stirring, 2.70g of FeCl 3 . 6H 2 O was dissolved in 100mL of ethylene glycol, and dissolved for 0.5h to obtain a yellow transparent solution, then 7.20g of anhydrous sodium acetate was added to the solution, and the stirring was continued for 0.5h, after which the solution was transferred to a stainless steel autoclave, sealed and heated at 200°C Heat the reaction for 8 hours, cool to room temperature after the reaction, and obtain black magnetic powdery solid particles, wash the solid particles with ethanol and water three times, and finally dry them under vacuum at 60°C for 12 hours to obtain magnetic microspheres;

[0048] (2) Preparation of xylan quaternary ammonium salt (QX): Place 0.33g xylan in a three-necked flask, add 10mL of anhydrous DMSO, and dissolve in an oil bath at 95°C for 1.5h under stirring conditions to obtain light The yellow solution was lowered to room temperature, then 200 μL...

Embodiment 3

[0053] (1) Magnetic microspheres (γ-Fe 2 o 3 ) preparation: under magnetic stirring, 2.70g of FeCl 3 . 6H 2 O was dissolved in 100mL of ethylene glycol, and dissolved for 0.5h to obtain a yellow transparent solution, then 7.20g of anhydrous sodium acetate was added to the solution, and the stirring was continued for 0.5h, after which the solution was transferred to a stainless steel autoclave, sealed and heated at 200°C Heat the reaction for 8 hours, cool to room temperature after the reaction, and obtain black magnetic powdery solid particles, wash the solid particles with ethanol and water three times, and finally dry them under vacuum at 60°C for 12 hours to obtain magnetic microspheres;

[0054] (2) Preparation of xylan quaternary ammonium salt (QX): Place 0.33g xylan in a three-necked flask, add 10mL of anhydrous DMSO, and dissolve in an oil bath at 95°C for 1.5h under stirring conditions to obtain light The yellow solution was lowered to room temperature, then 200 μL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com