Fin field effect transistor and formation method thereof

A fin-type field effect and transistor technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of low mobility and low saturation current of PMOS transistors, and achieve high mobility and hole-carrying current Improvement of sub-mobility, effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

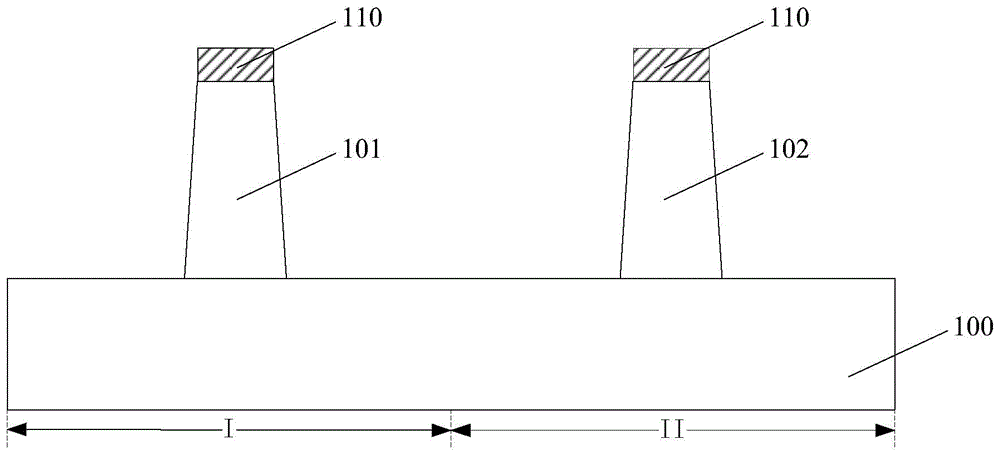

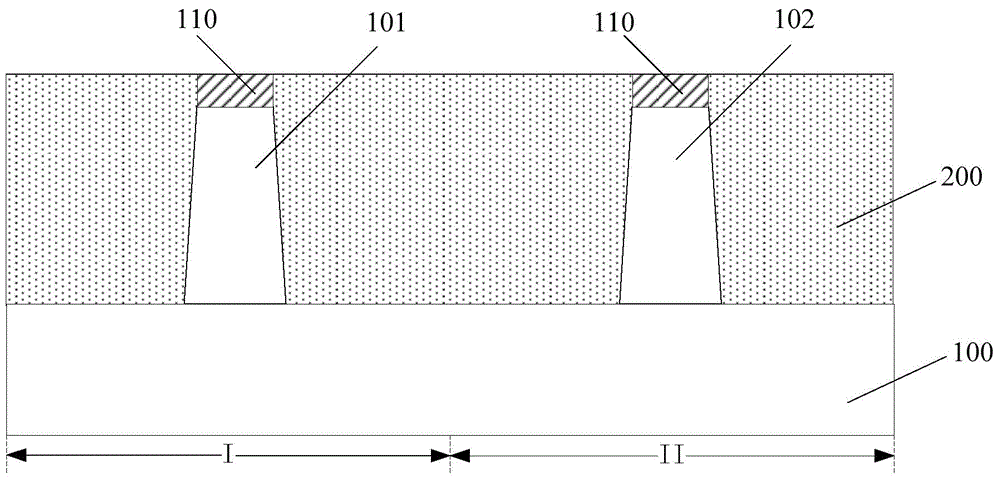

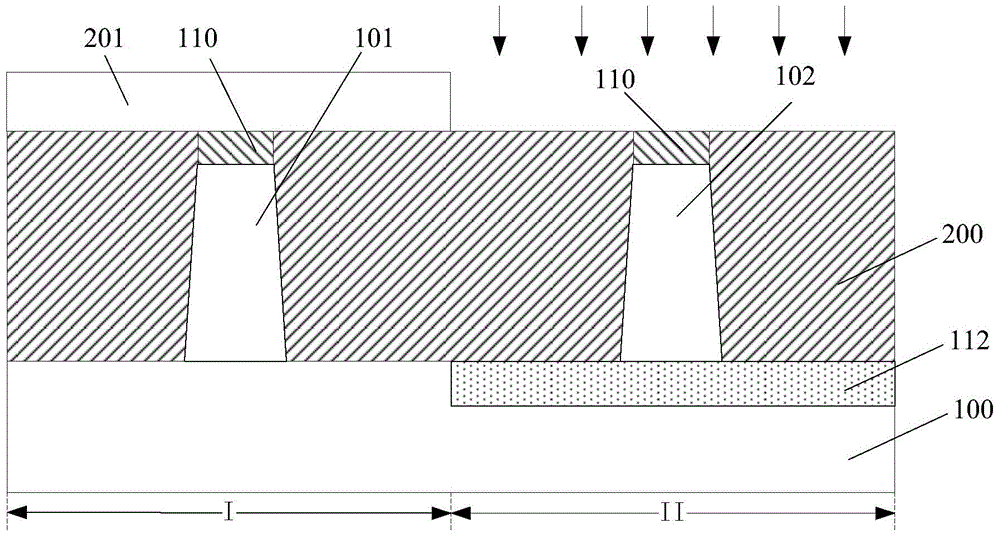

[0033] As mentioned in the background art, the performance of the P-type fin field effect transistor formed in the prior art needs to be further improved.

[0034] Studies have found that the migration rate of hole carriers in germanium or germanium-silicon materials in P-type fin field effect transistors is greater than that in silicon, and using germanium or germanium-silicon materials as fin materials can improve the performance of P-type fin field effect transistors. The hole mobility of the P-type fin field effect transistor, thereby improving the performance of the P-type fin field effect transistor. In one embodiment, a germanium layer or a silicon germanium layer may be formed by epitaxy on a substrate, and then the germanium layer or silicon germanium layer may be etched to serve as the channel region of the P-type fin field effect transistor. However, the yield of the single-crystal germanium layer formed by the epitaxial process is low and the cost is high, and ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com