Preparing method for concentrated milk protein powder used for producing semitransparent and transparent milk beverages

A technology of transparent milk beverage and concentrated milk protein, which is applied in the direction of milk protein composition, protein food composition, application, etc., can solve the problems of limited application, achieve the effect of small protein properties, increase protein content, and strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

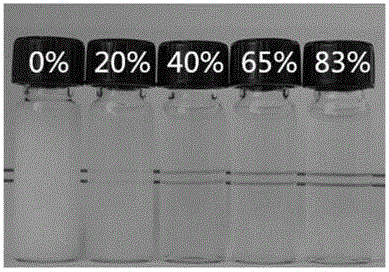

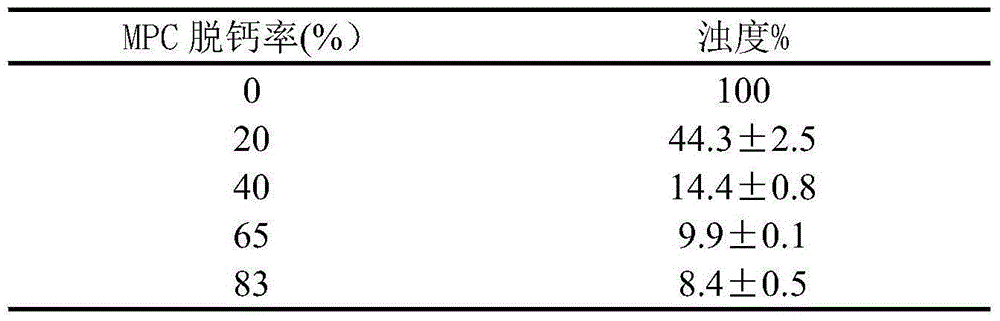

Image

Examples

Embodiment example 1

[0019] A kind of use skim milk as raw material, utilize strong acid type cation exchange resin to decalcify the method for reducing the solution turbidity after MPC redissolving, its specific process steps are as follows:

[0020] Take 240L of commercially available pasteurized degreasing, and use polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 10,000MWCO to treat it. The ultrafiltration temperature is 35°C. Concentrate 4 times to obtain 60L retentate. The retentate had a solids content of 12% and a pH of 6.8. Add 2.5-6 kg of strong acid cation exchange resin Amberlite SR1LNa, conduct ion exchange treatment at room temperature for 2 hours, the pH value is 7.3-7.7, and adjust the pH to 6.8. Falling film evaporation was performed below 70°C to a solids content of 20%. Finally, the decalcified MPC dry powder was obtained by spray drying at an inlet temperature of 175°C and an outlet temperature of 75°C. The final decalcification rate can reach 40-9...

Embodiment example 2

[0025] A kind of whole milk is used as raw material, utilizes strong acid type cation exchange resin to decalcify the method for reducing the solution turbidity after MPC reconstitution, and its specific process steps are as follows:

[0026] After removing fat from 500L fresh whole milk, it is treated with a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 10,000MWCO. The ultrafiltration temperature is 35°C. Once concentrated 5 times, 100L retentate was obtained. The retentate had a solids content of 15% and a pH of 6.8. Add 4 kg of strong-acid cation exchange resin Amberlite SR1LNa to treat at room temperature for 3 hours, the pH value is 7.4, and adjust the pH to 6.8. Falling film evaporation was carried out below 70°C to a solids content of 22%, and finally spray dried at 175 / 80°C. The final decalcification rate can reach 40%, and the turbidity is 14% (2% solution).

Embodiment example 3

[0028] A kind of reconstituted skim milk powder is used as raw material, utilizes weak acid type cation exchange resin to decalcify the method for reducing the solution turbidity after MPC reconstitutes, and its specific process steps are as follows:

[0029] Take 24kg of commercially available skim milk powder and redissolve it in 240L of deionized water to prepare a milk powder solution with a solid content of 10% (w / v), stir in a constant temperature water bath at 50°C for 1 hour, and homogenize twice under a homogenizing pressure of 28Mpa. Treated with a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 10,000MWCO, and the ultrafiltration temperature was 40°C. After one ultrafiltration and three diafiltrations, the first three concentration times were 3 times, and the last concentration was 4 times to obtain 60L of retentate. The pH of the retentate was 6.9. Add 2kg of weak acid type cation exchange resin DuoliteResinC433 for 2.5h, the pH value i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com