A kind of freezing method of liquid food

A liquid food and freezing method technology, which is applied in food freezing, food preservation, food science, etc., can solve the problems of limited reduction of supercooling degree, shortening of freezing time, and long total freezing time, etc., to achieve the reduction of supercooling degree, Effect of shortening freezing time and promoting heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take raw materials to be frozen: 90 parts of distilled water, 10 parts of sucrose, dissolve them completely to obtain a sucrose solution, and test the initial freezing point of the sucrose solution.

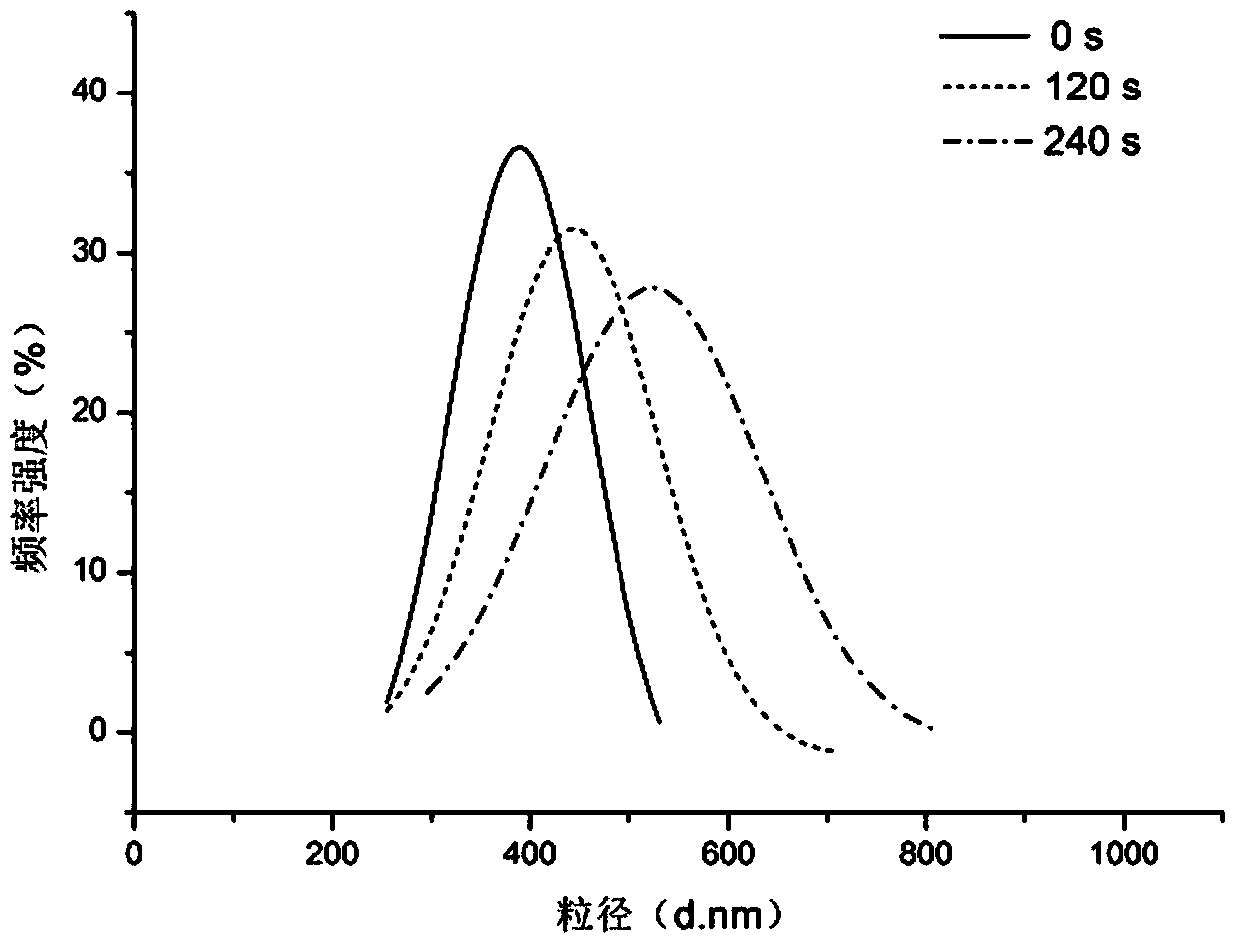

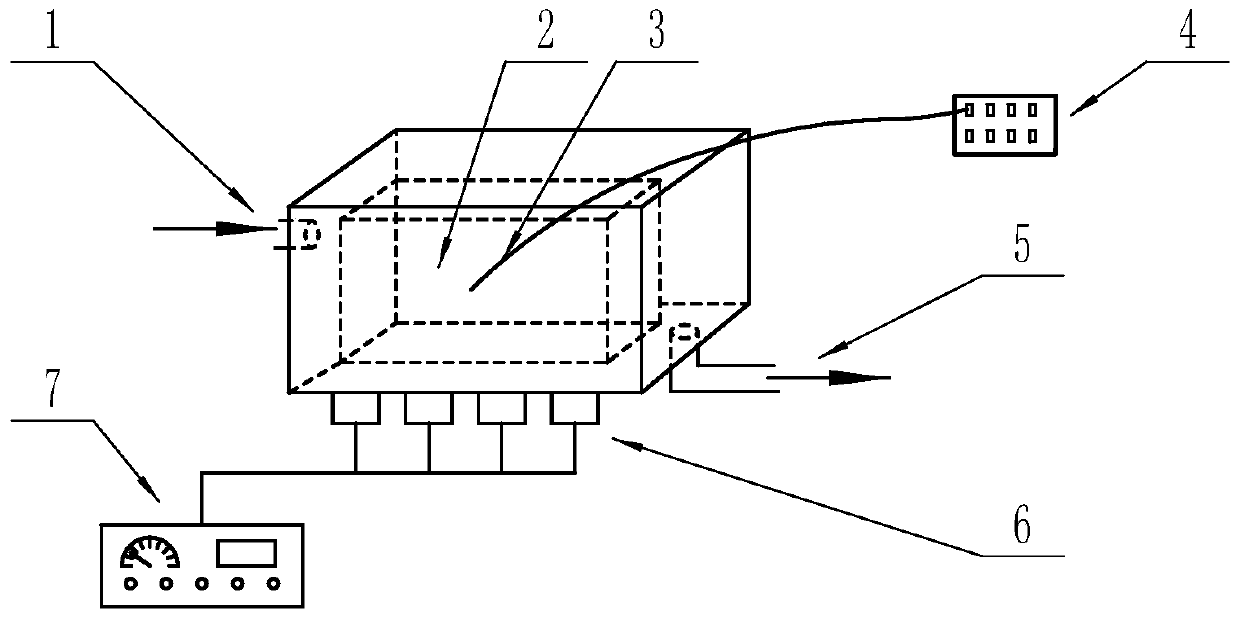

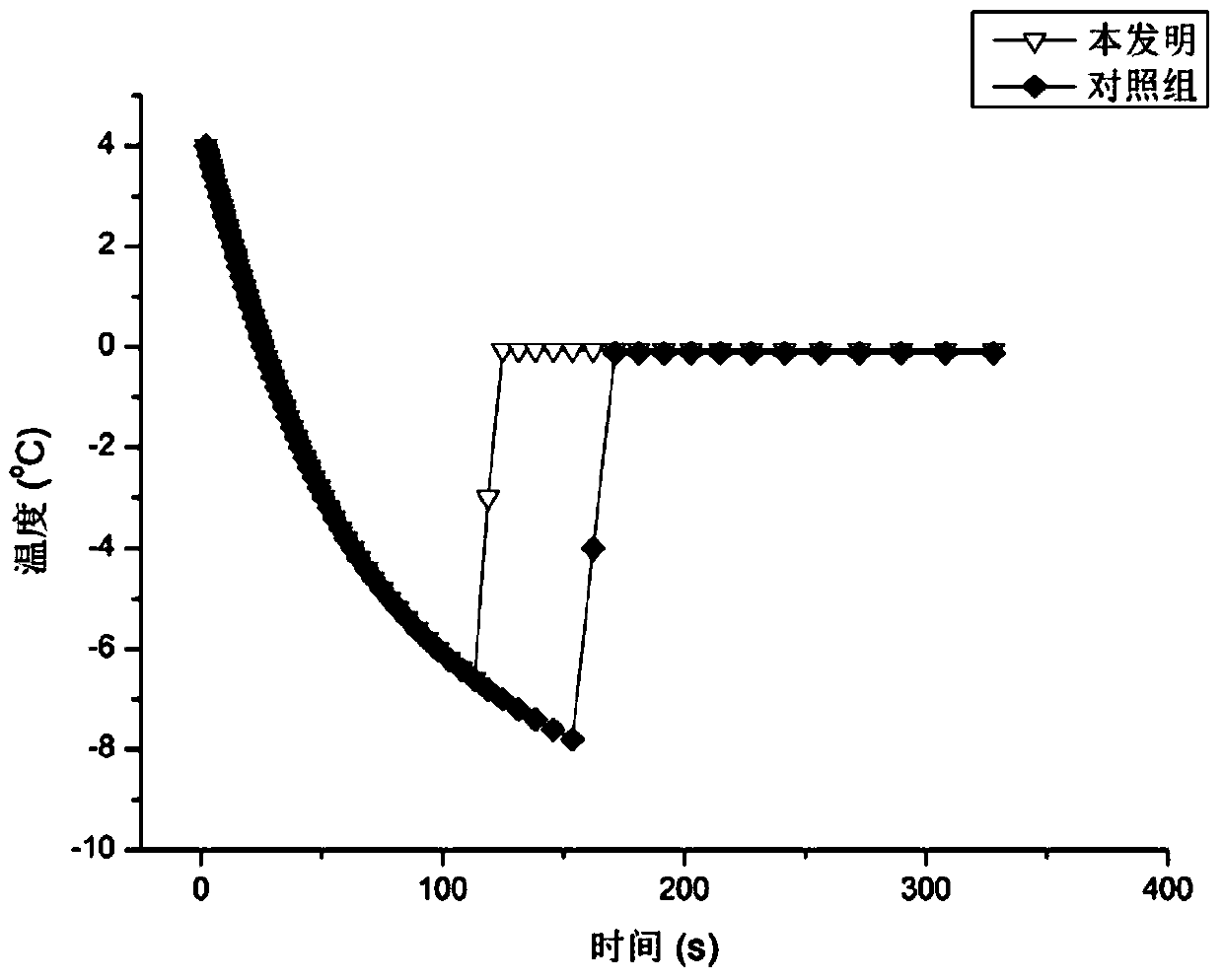

[0035] Circulate the solution for 5 minutes at 20°C with an ultra-micron bubble generator. After the cycle is complete, use a vortex flowmeter to check whether the gas content of the sample is between 82-90%, and the particle size of the bubbles is 300-800nm; if it has not reached range, recirculate for 1 to 2 minutes until the gas content reaches the range. figure 1 It is the distribution of the bubbles in the sucrose solution with a gas content rate of 85% after circulating through the micro bubble generator. Then, the bubble-laden sample was passed through an ultrasonic processor with a condensing circulation system. The temperature of the condensed circulating liquid is maintained at -20°C by the refrigeration system, and a T-type thermocouple is placed in the ultraso...

Embodiment 2

[0038] Raw materials to be frozen: 60 parts of distilled water, 35 parts of sucrose, and 5 parts of maltodextrin. It was completely dissolved to obtain a solution, and the initial freezing point of the solution was tested.

[0039] Use an ultra-micron bubble generator to circulate the solution for 5 minutes at room temperature. After the cycle is completed, use a vortex flowmeter to detect whether the gas content of the sample is between 82-90%, and the particle size of the bubbles is 300-800nm; if it has not reached the range , and recirculate for 1-2 minutes until the gas content reaches the range. Pass the bubble-laden sample through an ultrasonic processor with a condensing circulation system. The condensed circulating fluid is maintained at -22°C by a refrigeration system. Place 3 T-type thermocouples in different positions of the instrument. When the T-type thermocouple detects that the average temperature is -3°C, start 0.4W / cm 2 Ultrasound is carried out in a cycle...

Embodiment 3

[0041]Raw materials to be frozen: 2L of apple juice (11-13°Brix), test the initial freezing point of the apple juice. Circulate it with an ultra-micron generator at room temperature for 8 minutes. After the cycle is completed, use a vortex flowmeter to check whether the gas content of the sample is between 82 and 90%. If it has not reached the range, recirculate for 1 to 2 minutes until the gas content rate reaches the range. Pass the bubble-laden sample through an ultrasonic processor with a condensing circulation system. The condensed circulating fluid is maintained at -20°C by a refrigeration system. Place 3 T-type thermocouples in different positions of the instrument. When the T-type thermocouple detects that the average temperature is -2°C, start 0.5W / cm 2 Ultrasound is carried out in a cycle of working for 2s and pausing for 8s. When the average temperature drops to -2°C again, stop at 0.5W / cm 2 Ultrasonic and start 0.9W / cm 2 Ultrasound, with 2s work, 8s pause cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com