Tea packaging tin and manufacturing method thereof

A production method and technology for packaging cans, which are applied in the directions of packaging, transportation and packaging, special packaging objects, etc., can solve the problems of complex production process of inner and outer two-layer packaging, tea cannot be drunk at one time, high time and labor costs, and achieve food safety. Guaranteed, well sealed, not easy to contaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

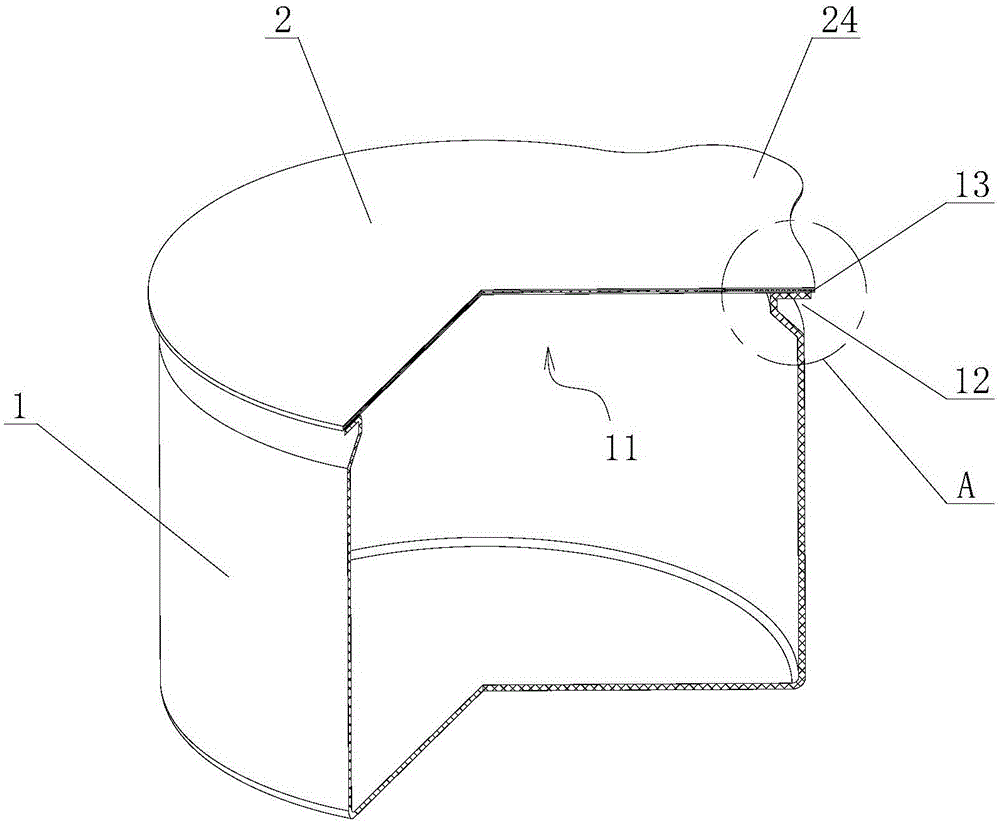

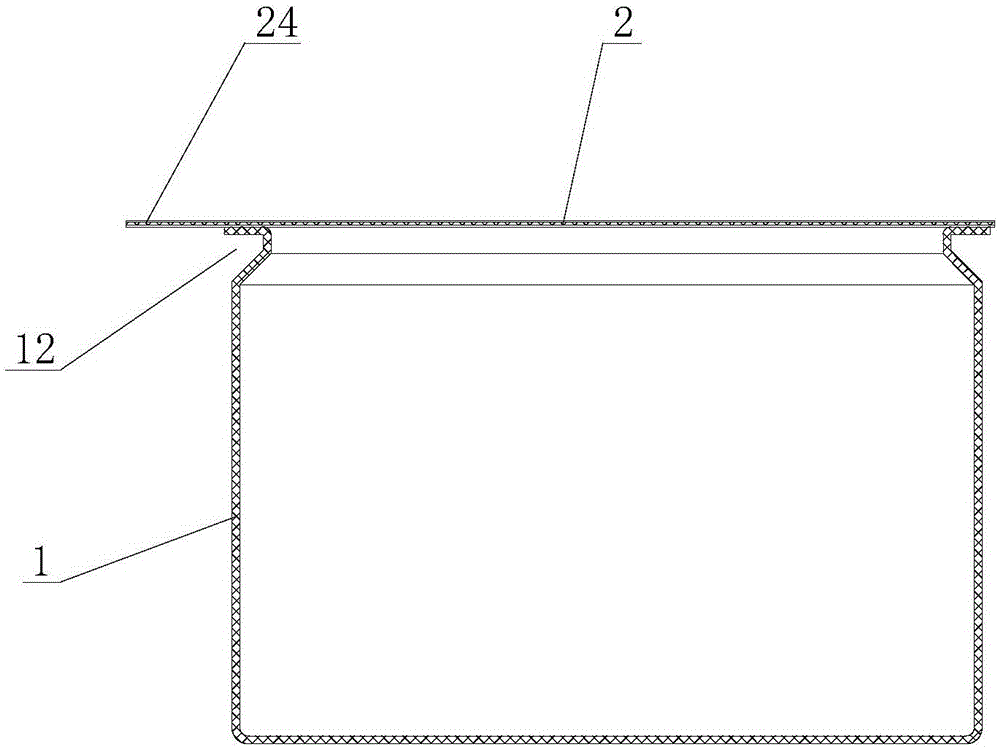

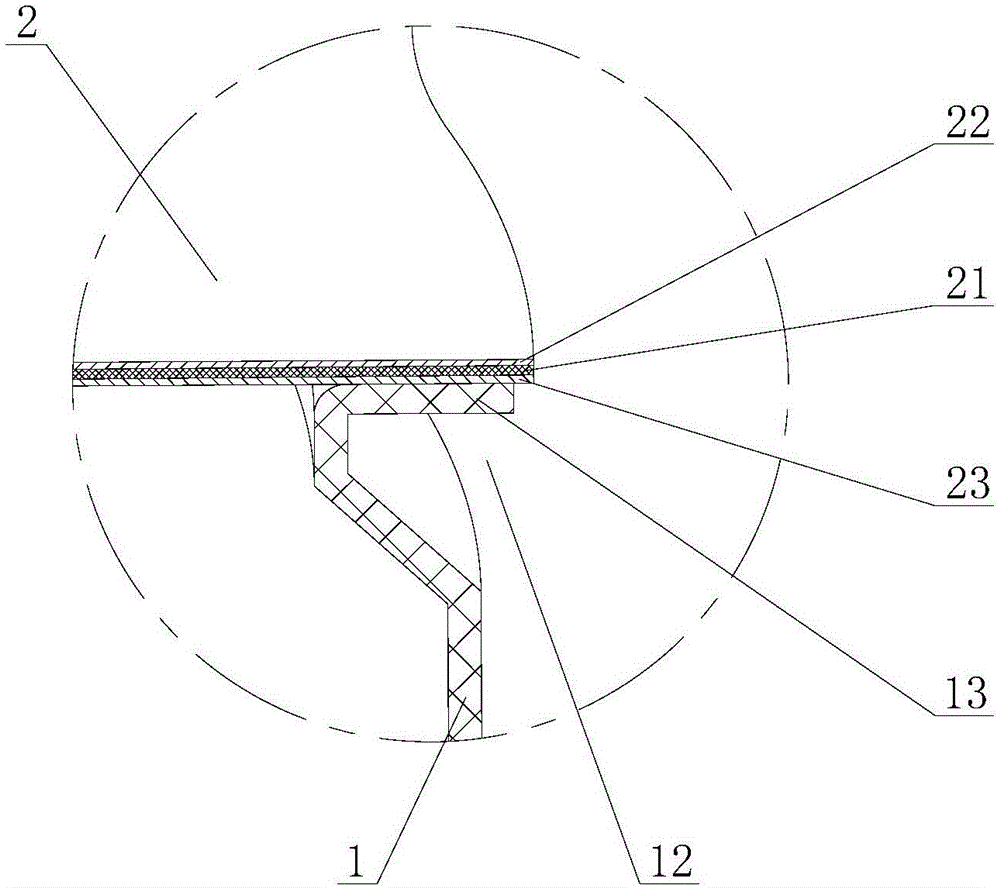

[0039] Such as figure 1 As shown, the present invention provides a tea packaging can, which includes an aluminum can body 1 and an aluminum top cover film 2 sealed and welded to the open end 11 of the aluminum can body, the upper side of the aluminum can body 1 The walls are recessed radially inwardly to form a ring groove 12 .

[0040] Specifically, the material of the aluminum tank body 1 is pure aluminum or aluminum alloy, which is generally cylindrical. The upper end of the aluminum tank body 1 forms an open end 11, and the lower end thereof is sealed. In this embodiment, the outer edge of the opening end 11 of the aluminum can body 1 forms an annular platform 13 radially outward, and the width of the annular platform 13 is 0.5mm-8mm. The open end 11 is provided with an annular platform 13, the purpose of which is to increase the contact area between the aluminum can body 1 and the aluminum top cover film 2 and facilitate welding.

[0041] In this embodiment, the upper s...

Embodiment approach 2

[0046] Such as Figure 1-3 Shown, the present invention also provides a kind of manufacturing method of tea packaging jar, it comprises the following steps:

[0047] a) providing an aluminum tank body, performing spinning processing on the upper side wall of the aluminum tank body 1, so that the upper side wall of the aluminum tank body 1 forms a ring groove 12;

[0048] b) flanging the opening end 11 of the aluminum tank body 1, so that the outer edge of the opening end 11 of the aluminum tank body 1 forms an annular platform 13 radially outward;

[0049] c) performing sandblasting and oxidation treatment on the aluminum tank body 1, and then putting tea leaves in the aluminum tank body 1;

[0050]d) heating the aluminum tank body 1 to a certain preset temperature;

[0051] e) Place the aluminum roof film 2 on the annular platform 13 of the aluminum tank body 1 , and weld the aluminum roof film 2 to the annular platform 13 of the aluminum tank body 1 .

[0052] Specificall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com