Soil heavy mental fixing agent and preparation method therefor and application thereof

A fixative and heavy metal technology, applied in the field of soil remediation, can solve the problem of limited adsorption and fixation of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0124] The present invention also provides a kind of preparation method of described fixing agent, comprises the steps:

[0125] 1) Provide component A, component B and lye, wherein,

[0126] Component A is biomass power plant ash particles;

[0127] Component B is a substance selected from the group consisting of alginic acid, alginate, or a combination thereof;

[0128] And the lye comprises a first solvent and an alkaline substance dissolved in the first solvent;

[0129] 2) under stirring conditions, adding the ash particles of the biomass power plant into the alkaline solution to obtain the first mixed solution;

[0130] 3) Under stirring conditions, heating the first mixed liquid obtained in step 2) to a first heat treatment temperature, adding the component B to the first mixed liquid at the first heat treatment temperature to obtain a second mixed liquid liquid;

[0131] 4) Heat treating the second mixed liquid obtained in step 3) at the first heat treatment temper...

Embodiment 1

[0161] Embodiment 1 Fixative 1

[0162] Add 10g of biomass power plant ash to 100mL of sodium hydroxide solution with a molar concentration of 0.5mol / L, stir for 30 minutes, then ultrasonicate for 10 minutes, stir and react at room temperature for 2 hours, filter and wash the reacted product, and dry at 40°C. Fixative 1 was obtained.

[0163] result

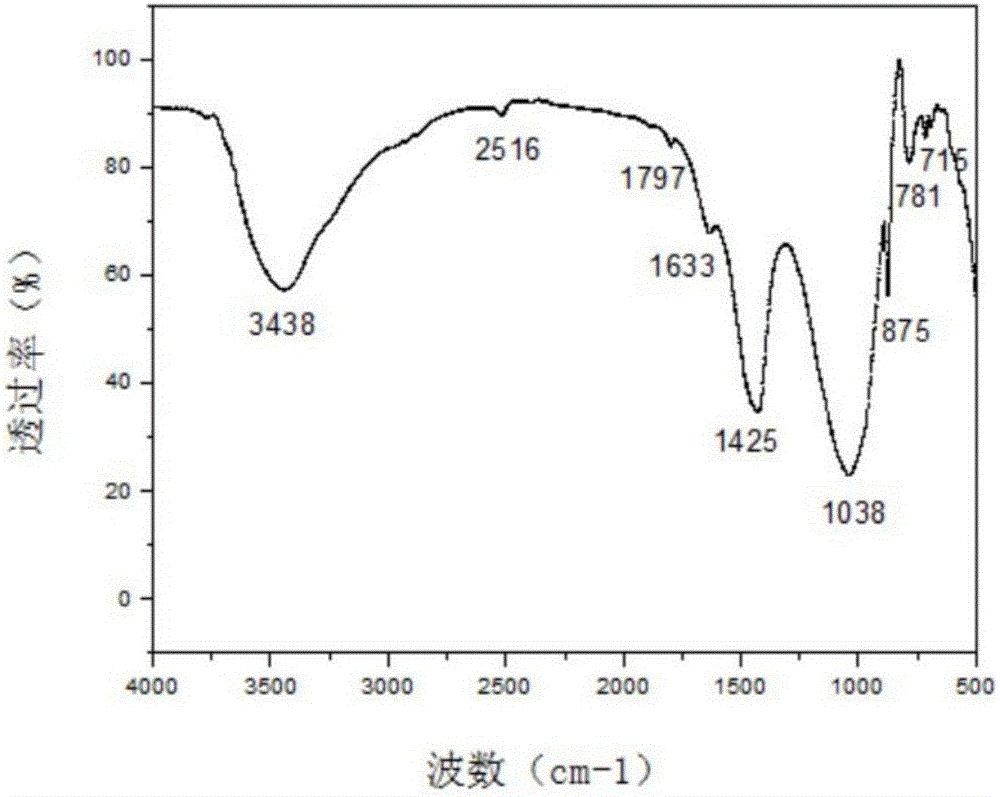

[0164] The obtained fixative was tested by XRD, TEM and FT-IR.

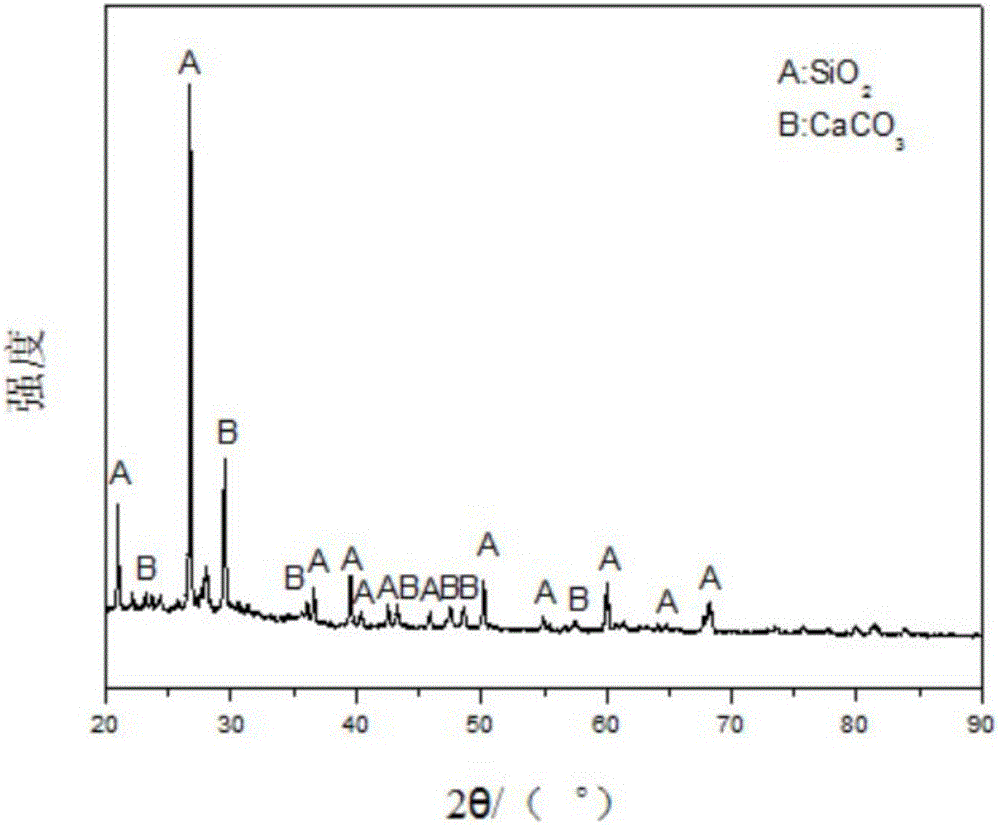

[0165] figure 1 It is the XRD collection of patterns of embodiment 1 gained fixing agent 1. from figure 1 It can be seen that the main components of the obtained fixing agent 1 are silicon dioxide and calcium carbonate.

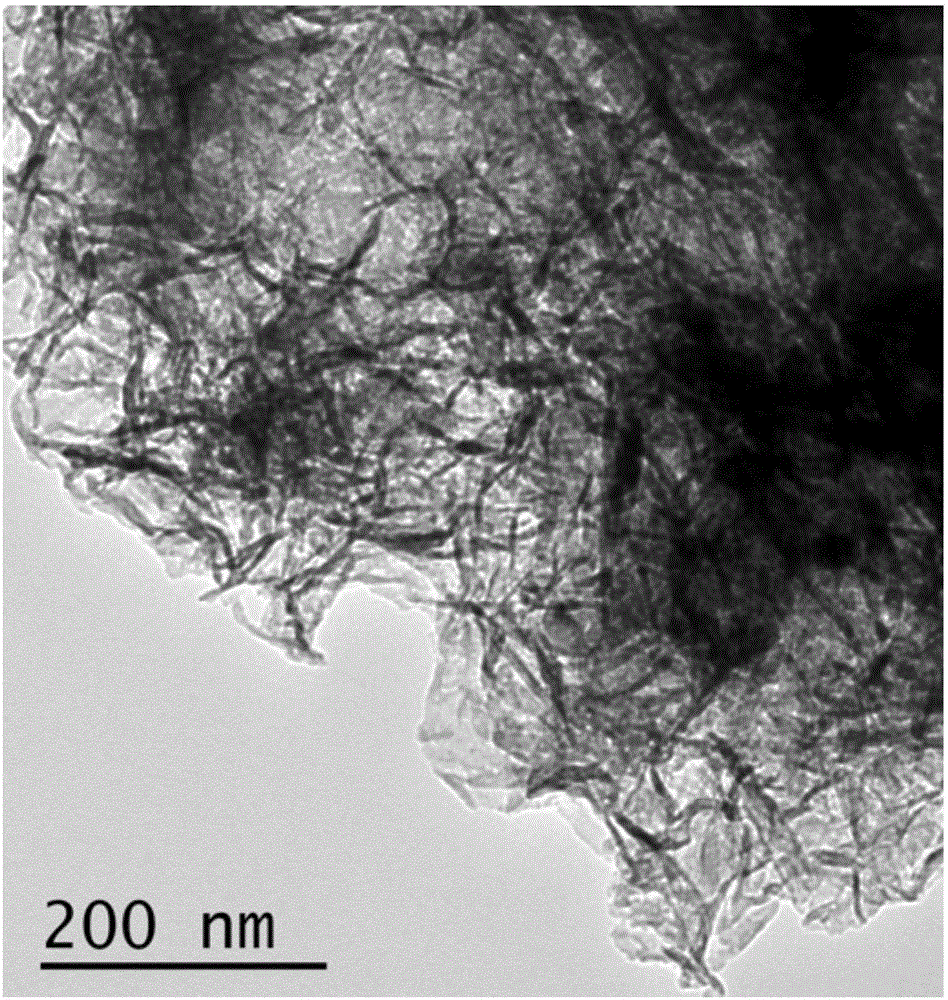

[0166] figure 2 It is the TEM picture of the fixative 1 obtained in Example 1. from figure 2It can be seen that the morphology of the obtained fixative 1 is different from that of the raw material power plant ash, which is mainly because the sodium hydroxide solution can convert a small amount of other carbonates on the surface of the cal...

Embodiment 2

[0168] Embodiment 2 Fixative 2

[0169] Add 20g of biomass power plant ash to 100mL of sodium hydroxide solution with a molar concentration of 0.1mol / L, stir and react at room temperature for 4 hours, filter and wash the reacted product with water, and dry at 40°C to obtain Fixative 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com