AISI410SS martensite stainless steel for valve and preparation process of AISI410SS martensite stainless steel

A martensitic stainless steel and preparation technology, applied in the field of metallurgy, can solve problems such as unstable quality, and achieve the effects of excellent surface quality, high forging efficiency, and high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

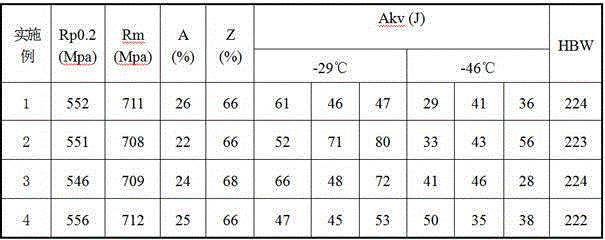

Examples

Embodiment Construction

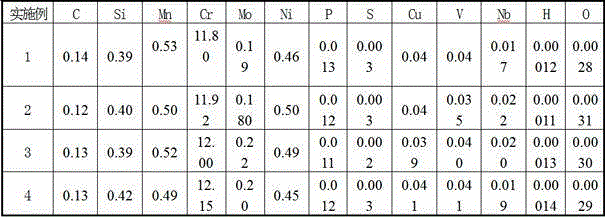

[0022] A valve body uses AISI410SS martensitic stainless steel. Its chemical composition is designed as follows: C=0.10~0.15%, Si=0.20~0.50%, Mn=0.30~0.60%, Cr=11.0~13.5%, Mo=0~ 0.6%, Ni=0.30~0.60%, S≤0.020%, P≤0.020%, Cu≤0.20%, V≤0.050%, Nb=0.010~0.080%, H≤0.00016%, O≤0.0035%, the remainder is Fe And impurity elements, the total impurity element content is ≤1.0%.

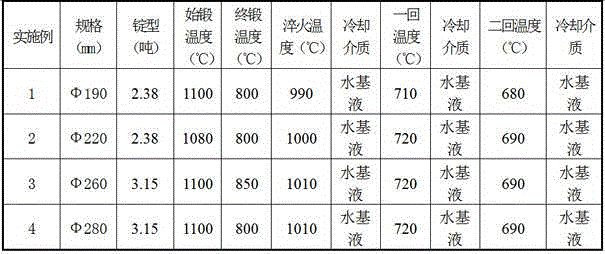

[0023] The preparation process of AISI410SS martensitic stainless steel for valve body is as follows:

[0024] Step 01: 1. ET preliminary refining in electric arc furnace. Preferably any one or several materials such as high-quality scrap steel, carbon (combined) steel head (chips), pig iron, sponge iron, etc. are used to form the charge to control the starting carbon oxidation, oxidation temperature, and decarburization amount ≥ 0.40%. Control [P]≤0.005% during electric arc furnace tapping, add sufficient precipitation deoxidizer, lime and appropriate amount of baked low-carbon ferrochrome to the ladle during tapping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com