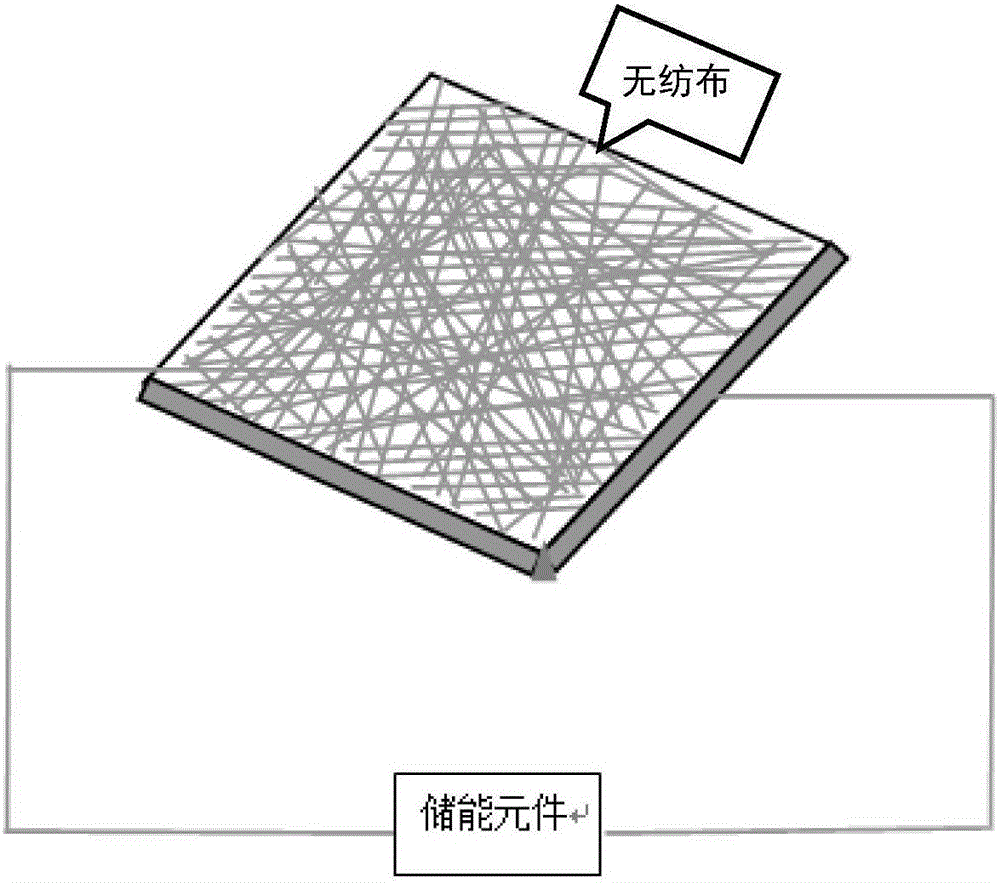

Large-area flexible piezoelectric spontaneous-heating non-woven fabric and manufacturing method thereof

A flexible piezoelectric and non-woven technology, used in non-woven fabrics, textiles and papermaking, etc., can solve problems such as the inability to meet a wide range of flexible use requirements, and achieve the effects of heating safety, enhanced circulation, and low current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a large-area flexible piezoelectric self-heating non-woven fabric, comprising the following steps:

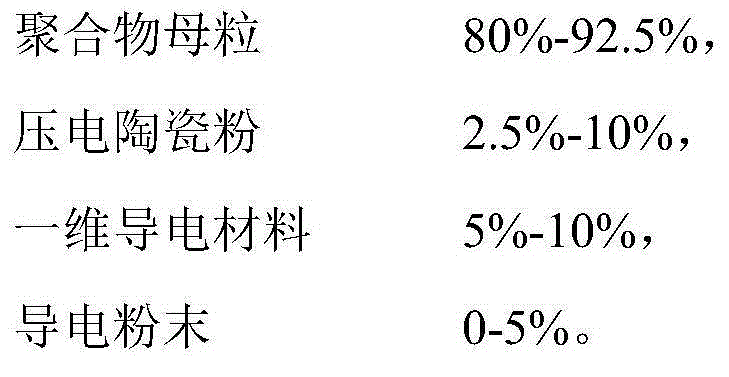

[0025] 1) According to PET (polyethylene terephthalate) masterbatch (ie polymer masterbatch), BaTiO 3 , carbon nanotubes, nano carbon powder (conductive nano carbon powder) mass ratio of 80:5:10:5, select polymer masterbatch (ie PET), piezoelectric ceramic powder (BaTiO 3 ), one-dimensional conductive material (carbon nanotube), conductive powder (nano carbon powder);

[0026] 2) Piezoelectric ceramic powder BaTiO 3 , one-dimensional conductive material, conductive powder and PET (polyethylene terephthalate) masterbatch are blended in a blender to make them evenly mixed to obtain a mixed material; put the evenly mixed mixed material into a twin-screw The extruder is melted and extruded and drawn at a uniform speed to obtain blended fibers (ie piezoelectric ceramic powder / one-dimensional conductive material / conductive powder / masterbatch blended fi...

Embodiment 2

[0030] A method for preparing a large-area flexible piezoelectric self-heating non-woven fabric, comprising the following steps:

[0031] 1) According to PET (polyethylene terephthalate) masterbatch (ie polymer masterbatch), PbZrO 3 , silver nanowires, nano-graphene powder mass ratio of 90:3:5:2, select polymer masterbatch, piezoelectric ceramic powder (PbZrO 3 ) and one-dimensional conductive materials (silver nanowires), conductive powders (graphene nanopowders);

[0032] 2) Piezoelectric ceramic powder PbZrO 3 , one-dimensional conductive material, conductive powder and PET (polyethylene terephthalate) masterbatch are blended in a blender to make them evenly mixed to obtain a mixed material; put the evenly mixed mixed material into a twin-screw The extruder is melted and extruded and drawn at a constant speed to obtain a blended fiber (ie piezoelectric ceramic powder / one-dimensional conductive material / conductive powder / masterbatch blended fiber); then the obtained blende...

Embodiment 3

[0036] A method for preparing a large-area flexible piezoelectric self-heating non-woven fabric, comprising the following steps:

[0037] 1) According to PET (polyethylene terephthalate) masterbatch (ie polymer masterbatch), PbTiO 3 , graphene nanoribbon, nano carbon powder (i.e. conductive nano carbon powder) mass ratio of 85:10:5:0, select polymer masterbatch, piezoelectric ceramic powder (PbTiO 3 ) and one-dimensional conductive material (graphene nanobelt) [the amount of conductive powder is 0];

[0038] 2) PbTiO 3 , Graphene nanoribbons and PET (polyethylene terephthalate) masterbatches are blended in a blender to make them evenly mixed to obtain a mixed material; put the evenly mixed mixed material into a twin-screw extruder Melt extrusion and uniform drafting to obtain blended fibers (ie piezoelectric ceramic powder / one-dimensional conductive material / conductive powder / masterbatch blended fiber); then the obtained blended fiber is granulated with a granulator, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com