An immersion liquid control device for immersion photolithography machine

A technology of immersion lithography and liquid control, which is applied in the direction of photolithography process exposure device, microlithography exposure equipment, etc., to achieve the effect of obvious restraint and improved sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

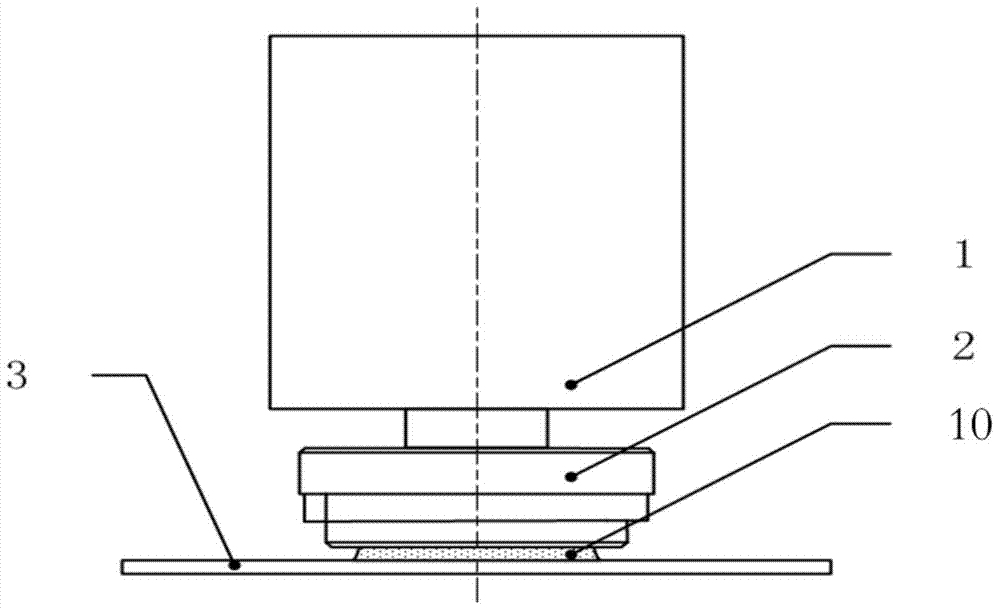

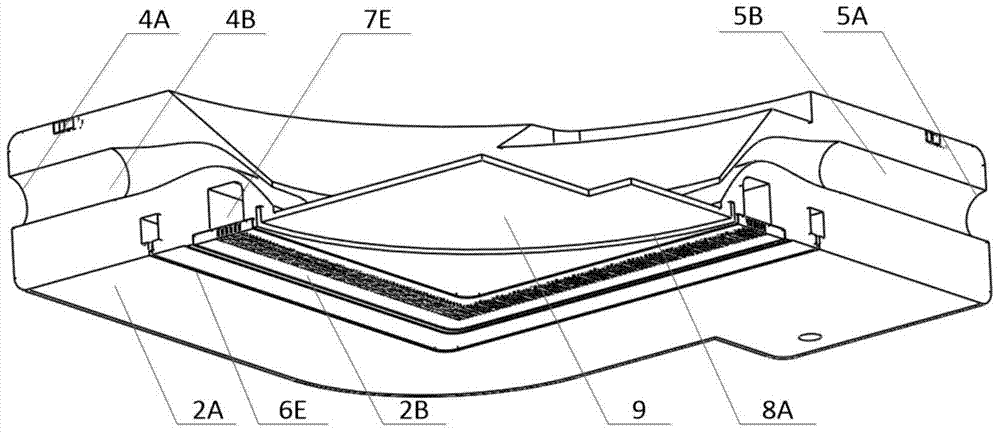

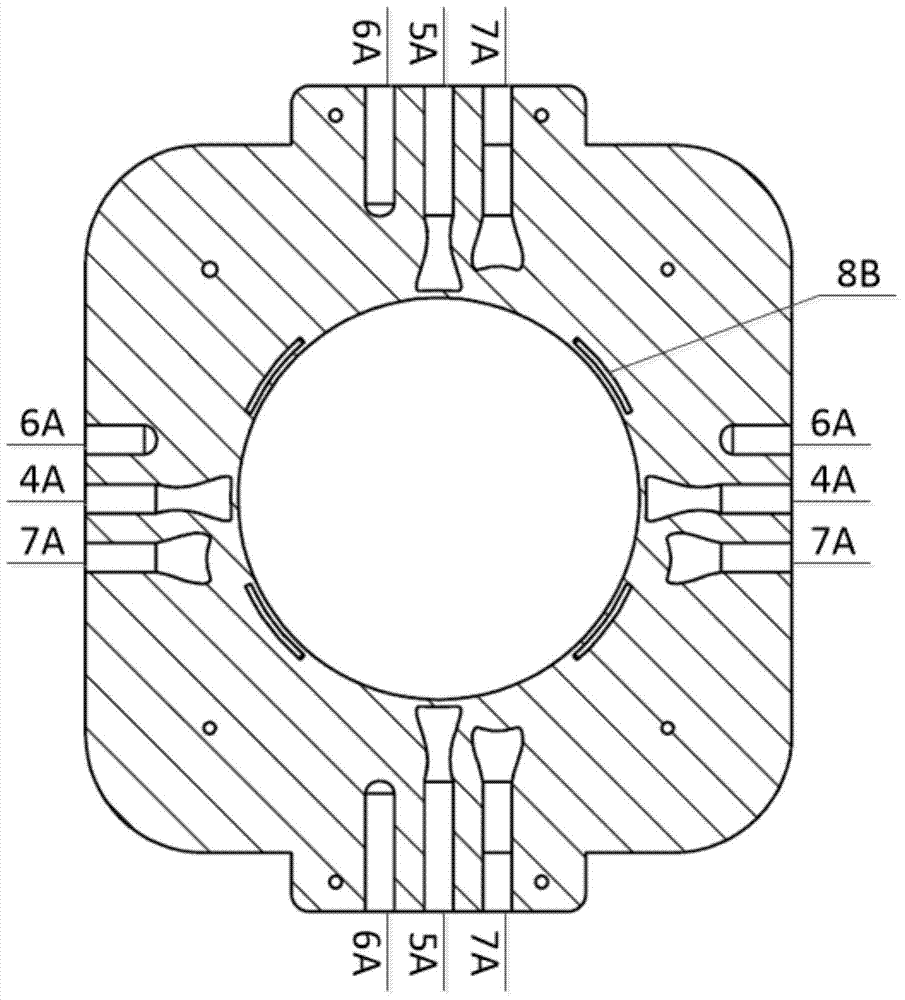

[0034] Such as figure 1 As shown, the immersion liquid control device 2 is installed between the projection objective lens group 1 and the silicon wafer 3. The immersion liquid control device 2 has a central rectangular through hole on the circular thin liner 9. The main function of the immersion liquid control device 2 is Confining the immersion liquid 10 directly below the projection objective lens group 1, the light emitted from the projection objective lens group 1 passes through the central through hole of the immersion liquid control device 2 and then enters the slit flow field, that is, it is irradiated on the silicon wafer 3 through the immersion liquid 10 Above, to complete the exposure process, the refractive index of the immersion liquid is higher than that of air, which can improve the numerical aperture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com