Urea hydrolysis reactor control system and urea hydrolysis reactor control method based on heat feed-forward signals

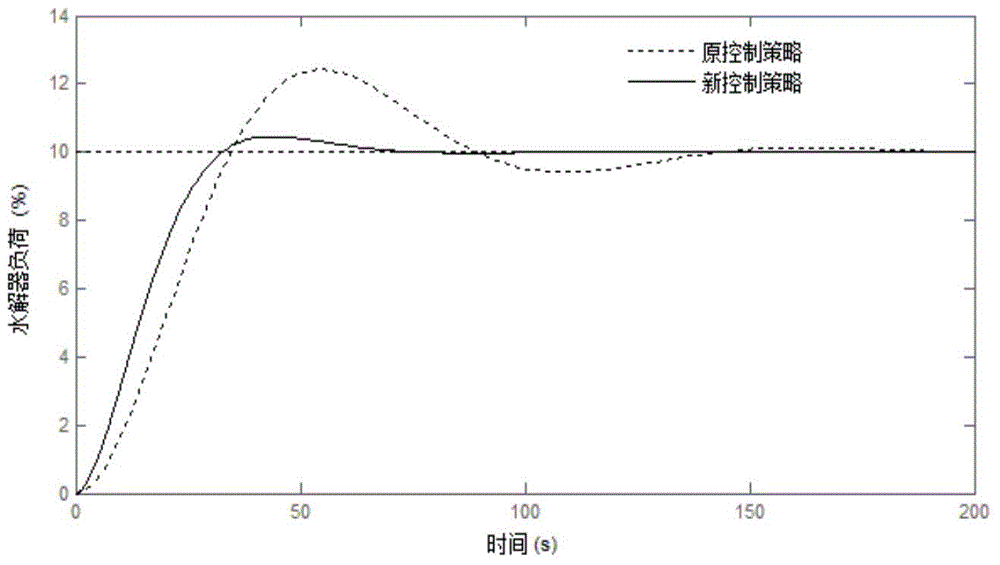

A hydrolysis reactor and feed-forward signal technology, which is applied to controllers with specific characteristics, electric controllers, etc., can solve problems such as slow changes in the working temperature of hydrolysis reactors, slow response speed to variable load commands, and frequent steam valve actions. , to achieve the effect of stable and reliable control signal, reduced amplitude and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

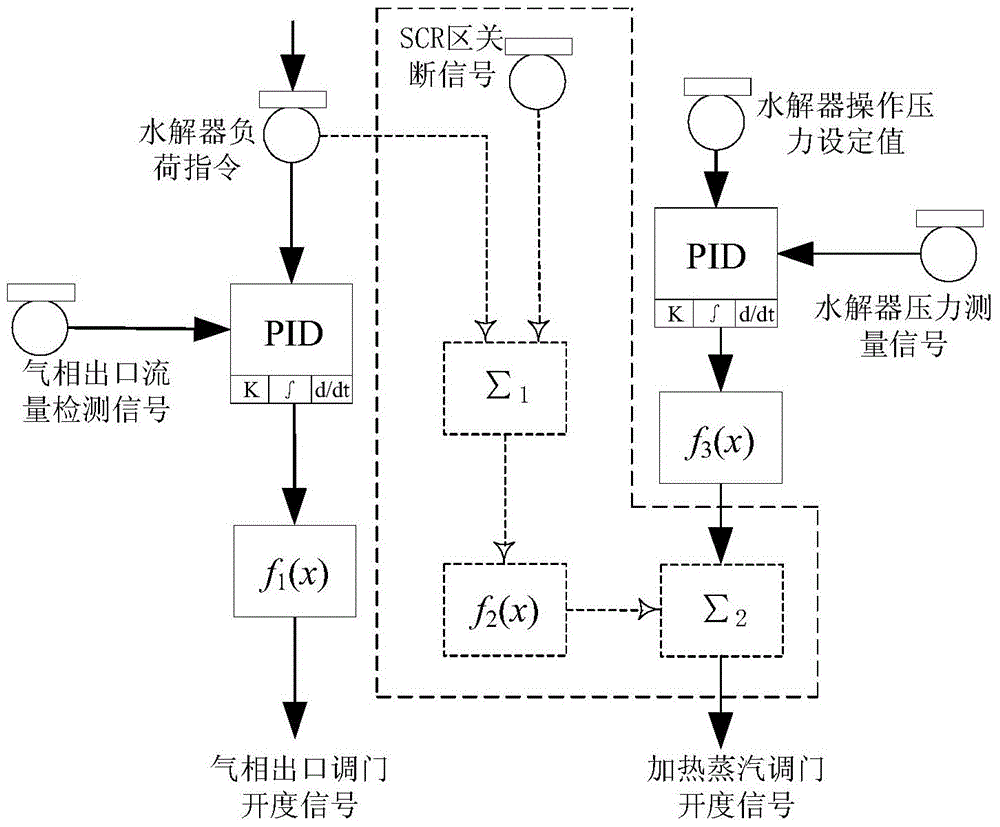

[0026] The present invention is based on the urea hydrolysis reactor control method of heat feed-forward signal, such as figure 1 As shown, it includes the following steps,

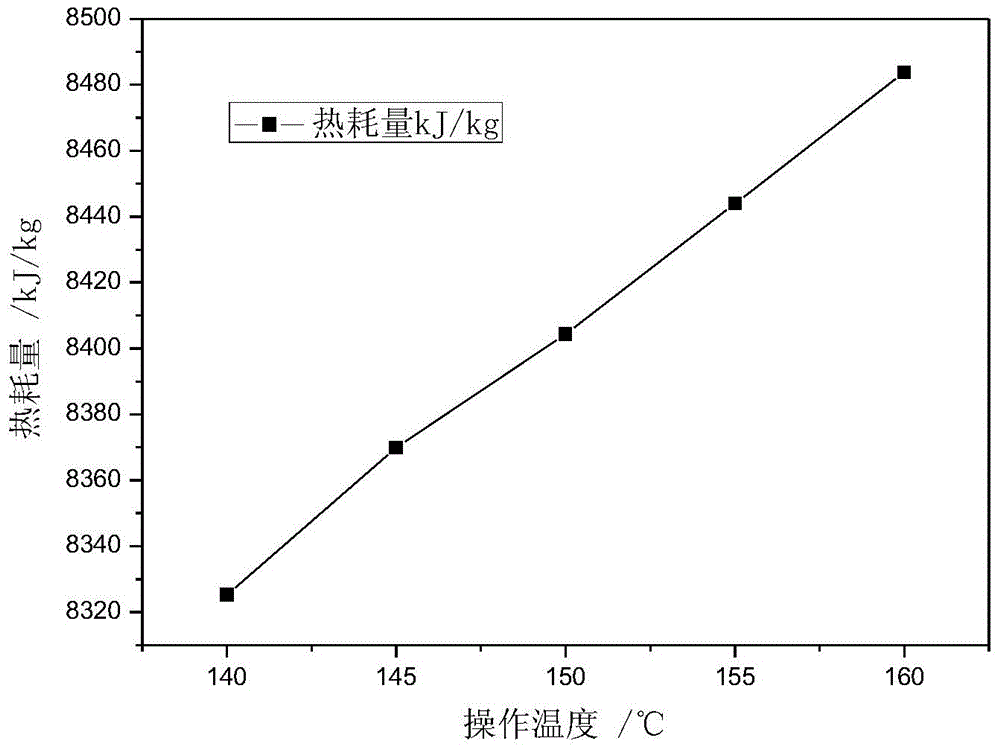

[0027] 1) The transfer function f from the load of the hydrolysis reactor to the amount of heating steam is obtained by fitting the operating data of the urea hydrolysis reactor 2 (x);

[0028] 2) From the hydrolysis reactor load command through the transfer function f 2 (x) generating a heating steam consumption signal, and converting it into a corresponding first heating steam regulating door opening signal according to the linear relationship between the heating steam consumption signal and the heating steam regulating door opening signal;

[0029] 3) According to the set value and measured value of the pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com