Nanometer micro-emulsion composition, preparation method thereof and application of nanometer micro-emulsion composition to cosmetic

A technology of microemulsion and composition, which is applied in the field of nano microemulsion composition and its preparation and application in cosmetics, can solve the problem of limited application range of gel emulsification method, difficulty in obtaining clear and transparent materials, product safety and Stickiness problem and other problems, to achieve the effect of not easy to delaminate, easy to absorb, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

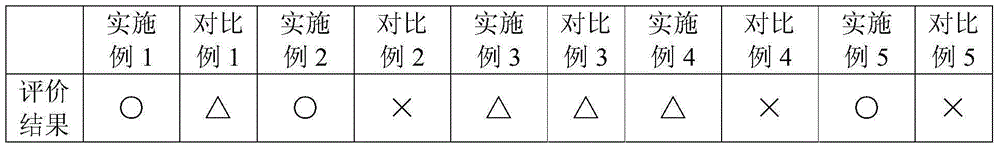

Examples

Embodiment 1

[0044] A kind of preparation of nano microemulsion composition:

[0045] Mix 11.2 parts by weight of surfactant (cocamidopropyl betaine) and 27.5 parts by weight of oil phase (isomeric hexadecane), and heat up to completely dissolve at 80°C to obtain a mixed system; slowly mix 27 parts by weight 34.3 parts by weight of deionized water are heated up to 80°C, and the surfactant, oil phase, The glycerin mixture was added into deionized water, stirred at a speed of 38 rpm until clear and transparent, and cooled to obtain a nano-microemulsion composition. The viscosity of the prepared composition is 3870mPa·s; the particle size of the particles is 10-100nm.

Embodiment 2

[0047] A kind of preparation of nano microemulsion composition:

[0048]20 parts by weight of the surfactant (14 parts by weight of polyglycerol fatty acid ester and 6 parts by weight of laurate) and 10 parts by weight of the oil phase (jojoba oil) are heated to completely dissolve at 80 ° C; slowly 30 parts by weight Parts by weight of glycerin are heated to 80°C, and added to polyglycerol fatty acid ester, laurate and jojoba oil to obtain a mixture; 40 parts by weight of deionized water is raised to 80°C, and the surfactant, oil phase The mixture of glycerin and glycerin was added into deionized water, stirred at a speed of 35 rpm until clear and transparent, and cooled to obtain a nano-microemulsion composition. The viscosity of the prepared composition is 4250mPa·s; the particle size of the particles is 10-100nm.

Embodiment 3

[0050] A kind of preparation of nano microemulsion composition:

[0051] Heat 1 part by weight of surfactant (hydrogenated castor oil) and 0.1 part by weight of oil phase (macadamia nut oil) at 75°C until completely dissolved; slowly raise the temperature of 0.5 part by weight of glycerin to 75°C, and add to hydrogenated castor oil and macadamia nut oil to obtain a mixture; heat up 40 parts by weight of deionized water to 80°C, slowly add the mixture of surfactant, oil phase and glycerin to deionized water, and stir at a speed of 30 rpm until clear and transparent , cooling down to obtain the nano microemulsion composition. The viscosity of the prepared composition is 1550mPa·s; the particle size of the particles is 10-100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com