Method for pretreating landfill leachate by quasi aerobiotic landfilling body

A landfill leachate, quasi-aerobic technology, applied in the direction of aerobic and anaerobic process treatment, can solve the problems of large difference in denitrification effect, impact and high investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

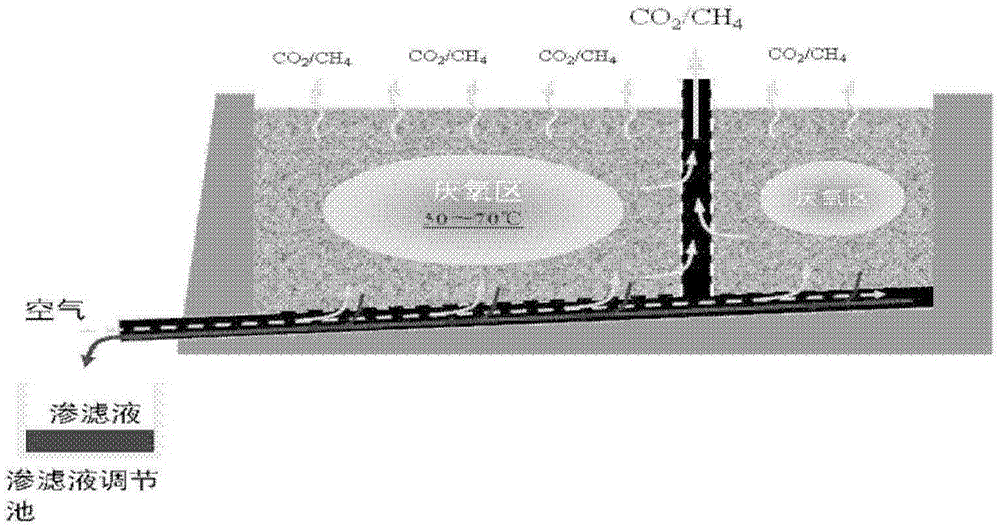

[0068] The municipal solid waste landfill test was carried out in an indoor simulated landfill device from April 2006 to June 2007. The simulated landfill device was made of PVC material and fixed with a steel frame structure. In the landfill test, two treatments were set up, quasi-aerobic landfill and anaerobic landfill, and the size of the landfill structure was 1.0m×1.5m×1.8m. The waste for testing comes from municipal solid waste in Beijing Asuwei landfill, and its moisture, organic matter and ash contents are 52.9%, 48.3% and 51.7% respectively. The amount of garbage used in the landfill test is about 1600kg, and the compacted density of the landfill garbage is about 0.73t m -3 , the porosity is about 27.0%.

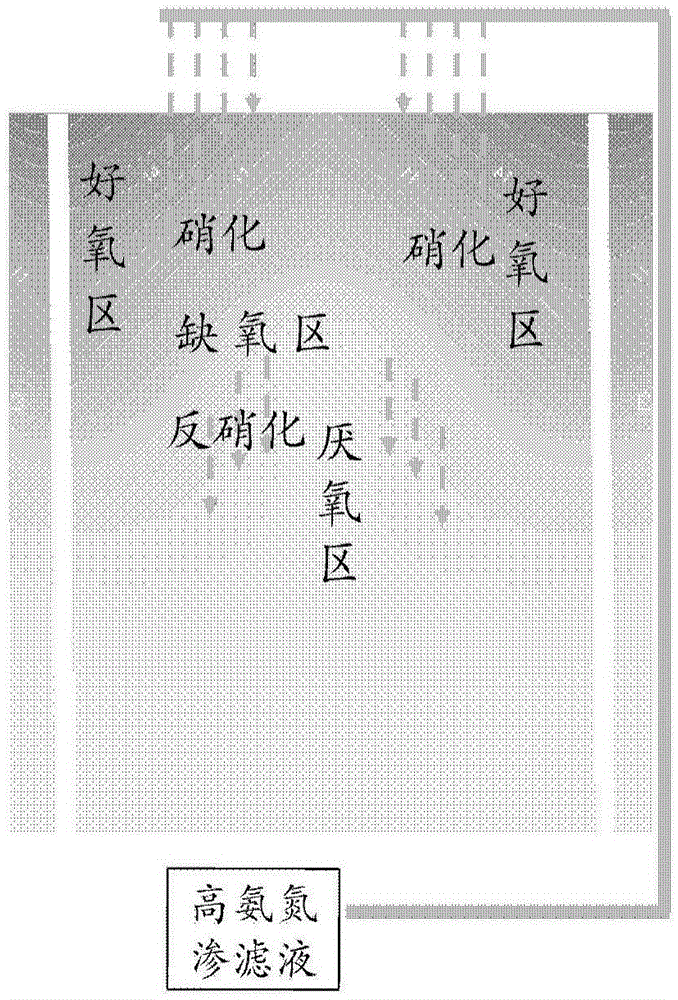

[0069] HDPE membranes are laid on the bottom of the quasi-aerobic landfill structure, and a leachate drainage layer (gravel, 50cm in thickness) is laid on the membrane, and a leachate drainage pipe (5cm in diameter) is laid in between. A vertical perforated air du...

Embodiment 2

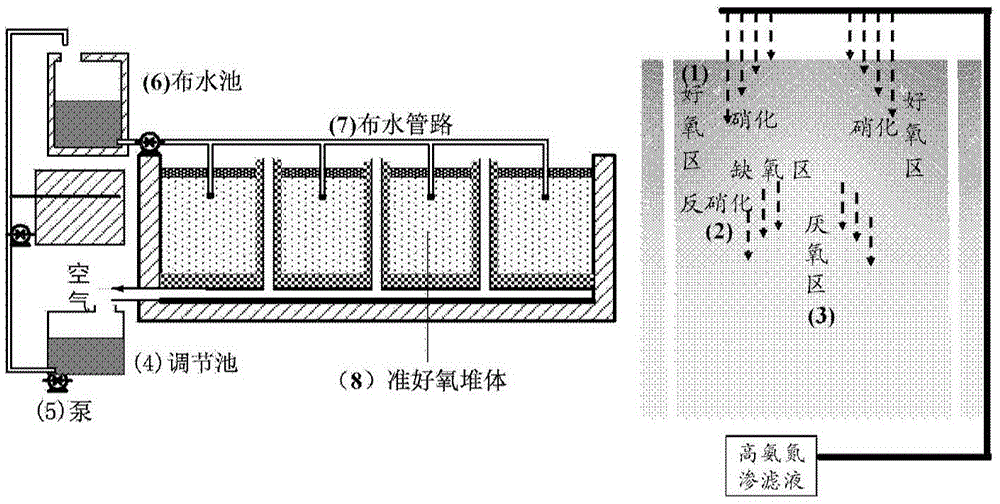

[0073] The municipal solid waste landfill test was carried out from November 2003 to October 2004 at the domestic waste landfill site in Jiujiang City, Jiangxi Province. The size of the landfill structure is 21m×3.8m×6.0m. The test material is urban domestic waste in Jiujiang City, and two treatments are set up, quasi-aerobic landfill and anaerobic landfill respectively. The amount of landfill waste is 250 tons, and the compaction density of landfill waste is about 0.52 tons / m 3 , the porosity is about 37.9%.

[0074] HDPE membranes are laid on the bottom of the quasi-aerobic landfill structure, and a leachate drainage layer (gravel, thickness 50cm) is laid on the membrane, and a corrugated pipe with a diameter of 0.2m is laid horizontally at the bottom of the landfill structure as the main leachate collection pipeline , The length of the leachate drainage pipe is about 22m. A gravel gabion is laid around the leachate drainage pipe for protection, and the diameter of the gabi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com