Method for smearing lithium nitrite mortar on surface of reinforced concrete to resist rust

A technology of reinforced concrete and lithium nitrite, which is applied in the field of anti-corrosion application of lithium nitrite mortar on the surface of reinforced concrete, can solve problems such as slowness, and achieve the effect of easy penetration, simple and effective operation, and accelerated penetration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

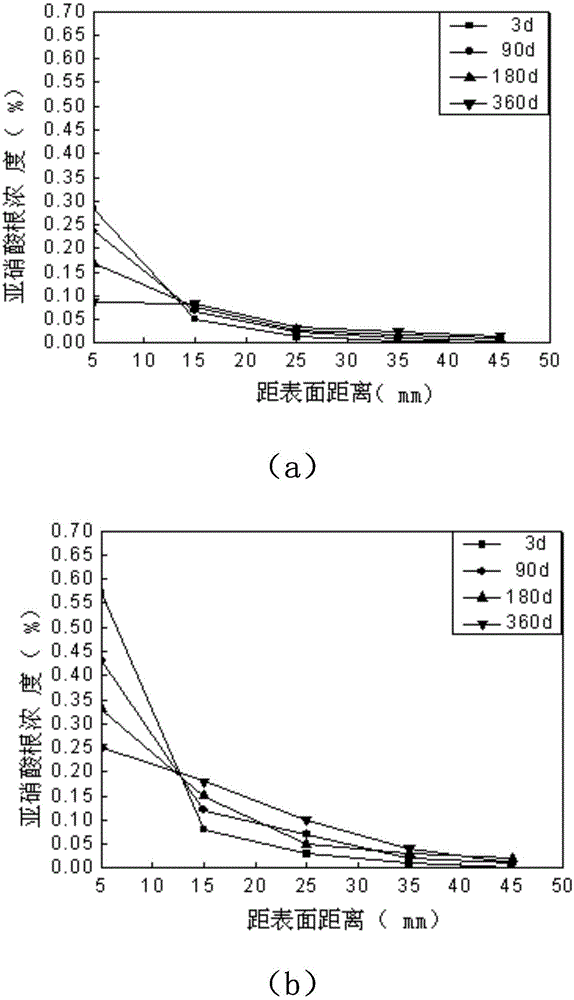

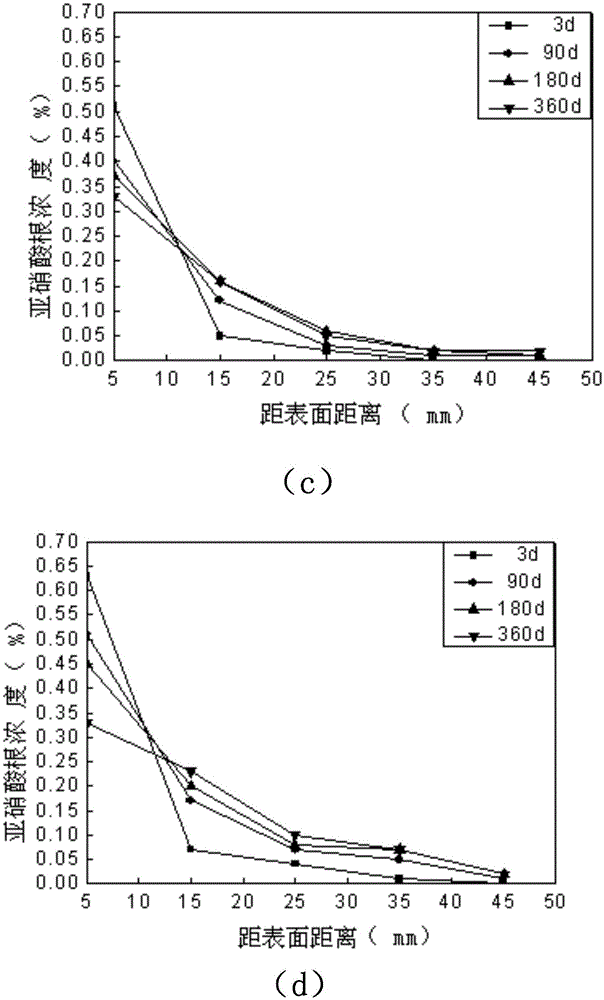

Image

Examples

Embodiment 1

[0018] Embodiment one: Lithium nitrite mortar smears antirust method on reinforced concrete surface, comprises following specific steps:

[0019] (1) Test the reinforced concrete structure with a steel corrosion tester to find out the rusted parts;

[0020] (2) Use a grinder to grind off the concrete structure of the rusted part by 5mm;

[0021] (3) Deploying lithium nitrite into a saturated aqueous solution of lithium nitrite;

[0022] (4) Moisten the polished surface with a saturated aqueous solution of lithium nitrite to form a water film on the polished surface;

[0023] (5) Evenly mix lithium nitrite with mortar to prepare lithium nitrite mortar, wherein the mass ratio of lithium nitrite to cement in the mortar is 2.5:100;

[0024] (6) Apply the lithium nitrite mortar on the grinding surface until it is level with the surrounding concrete structure. After the final setting and hardening of the lithium nitrite mortar, water it for curing at room temperature.

Embodiment 2

[0025] Embodiment two: Lithium nitrite mortar smears anti-corrosion method on reinforced concrete surface, comprises the following specific steps:

[0026] (1) Test the reinforced concrete structure with a steel corrosion tester to find out the rusted parts;

[0027] (2) Use a grinder to grind off the concrete structure of the rusted part by 10mm;

[0028] (3) Deploying lithium nitrite into a saturated aqueous solution of lithium nitrite;

[0029] (4) Moisten the polished surface with a saturated aqueous solution of lithium nitrite to form a water film on the polished surface;

[0030] (5) Evenly mix lithium nitrite with mortar to prepare lithium nitrite mortar, wherein the mass ratio of lithium nitrite to cement in the mortar is 2:100;

[0031] (6) Apply the lithium nitrite mortar on the grinding surface until it is level with the surrounding concrete structure. After the final setting and hardening of the lithium nitrite mortar, water it for curing at room temperature.

Embodiment 3

[0032] Embodiment three: Lithium nitrite mortar is coated with antirust method on reinforced concrete surface, comprises the following specific steps:

[0033] (1) Test the reinforced concrete structure with a steel corrosion tester to find out the rusted parts;

[0034] (2) Use a grinder to grind off the concrete structure of the rusted part by 8mm;

[0035] (3) Deploying lithium nitrite into a saturated aqueous solution of lithium nitrite;

[0036] (4) Moisten the polished surface with a saturated aqueous solution of lithium nitrite to form a water film on the polished surface;

[0037] (5) Evenly mix lithium nitrite with mortar to prepare lithium nitrite mortar, wherein the mass ratio of lithium nitrite to cement in the mortar is 2.2:100;

[0038] (6) Apply the lithium nitrite mortar on the grinding surface until it is level with the surrounding concrete structure. After the final setting and hardening of the lithium nitrite mortar, water it for curing at room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com