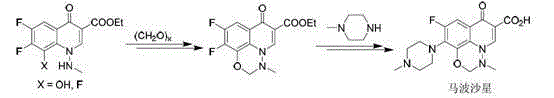

Preparation for marbofloxacin key intermediate

A technology of marbofloxacin and intermediates, applied in the field of medicinal chemistry, can solve the problems of too long reaction route, expensive chemical reagents, unfavorable use and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

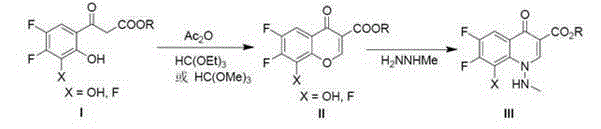

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of 6,7,8-trifluoro-4-oxo-4-hydrogen-benzopyran-3-carboxylic acid ethyl ester (formula II, X=F, R=Et)

[0031] 3-(3,4,5-trifluoro-2-hydroxyphenyl)-3-keto-propionic acid ethyl ester (formula I, X=F, R=Et) (50g, 0.191mmol, 1.0eq), original A mixture of triethyl formate (85g, 0.574mmol, 3.0eq) and acetic anhydride (100g, 0.98mmol, 5.1eq) was heated in an oil bath until the system refluxed, and the refluxed state was kept for 24 hours. After the system cooled down, it was concentrated on a rotary evaporator, and the residue was added to ethyl acetate (1000L), and the obtained organic solution was washed twice with saturated sodium bicarbonate solution (2×200mL) and once with brine (100mL). Dry over sodium sulfate, filter out the desiccant, concentrate the obtained organic phase under reduced pressure, recrystallize the residue using a mixed solvent of ethyl acetate and heptane, and dry the product in vacuum at 60°C to constant weight to obtain a light ...

Embodiment 2

[0032] Example 2: Preparation of 6,7,8-trifluoro-4-oxo-4-hydrogen-benzopyran-3-carboxylic acid ethyl ester (formula II, X=F, R=Et)

[0033] 3-(3,4,5-trifluoro-2-hydroxyphenyl)-3-keto-propionic acid ethyl ester (formula I, X=F, R=Et) (50g, 0.191mmol, 1.0eq), original A mixture of triethyl formate (65g, 0.44mmol, 2.3eq) and acetic anhydride (78g, 0.76mmol, 4.0eq) was heated in an oil bath until the system refluxed, and the refluxed state was kept for 6 hours. After the system cooled down, it was concentrated on a rotary evaporator, and the residue was added to ethyl acetate (1000L), and the obtained organic solution was washed twice with saturated sodium bicarbonate solution (2×200mL) and once with brine (100mL). Dry over sodium sulfate, filter out the desiccant, and concentrate the obtained organic phase under reduced pressure. The residue is recrystallized with a mixed solvent of ethyl acetate and heptane, and the product is vacuum-dried at 60°C to constant weight to obtain a ...

Embodiment 3

[0034] Example 3: Preparation of 6,7-difluoro-8-hydroxyl-4-oxo-4-hydrogen-chromene-3-carboxylic acid methyl ester (formula II, X=OH, R=Me)

[0035]3-(4,5-difluoro-2,3-dihydroxyphenyl)-3-keto-propionic acid methyl ester (formula I, X=OH, R=Me) (50g, 0.20mmol, 1.0eq), A mixture of trimethyl orthoformate (51g, 0.48mmol, 2.4eq) and acetic anhydride (105g, 1.03mmol, 5.1eq) was heated in an oil bath until the system refluxed, and the refluxed state was kept for 12 hours. After the system cooled down, it was concentrated on a rotary evaporator, and the residue was added to ethyl acetate (1000L), and the obtained organic solution was washed twice with saturated sodium bicarbonate solution (2×200mL) and once with brine (100mL). Dry over sodium sulfate water, filter out the desiccant, concentrate the obtained organic phase under reduced pressure, recrystallize the residue using a mixed solvent of ethyl acetate and heptane, and dry the product in vacuum at 60°C to constant weight to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com