Preparation method of deodorizing type flexible polyurethane foam containing long-acting and slow-release plant essential oil

A plant essential oil and soft foam technology, which is applied in the field of preparation of deodorant long-acting slow-release plant essential oil polyurethane soft foam, can solve the problems of no deodorant performance and achieve the effect that it is not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

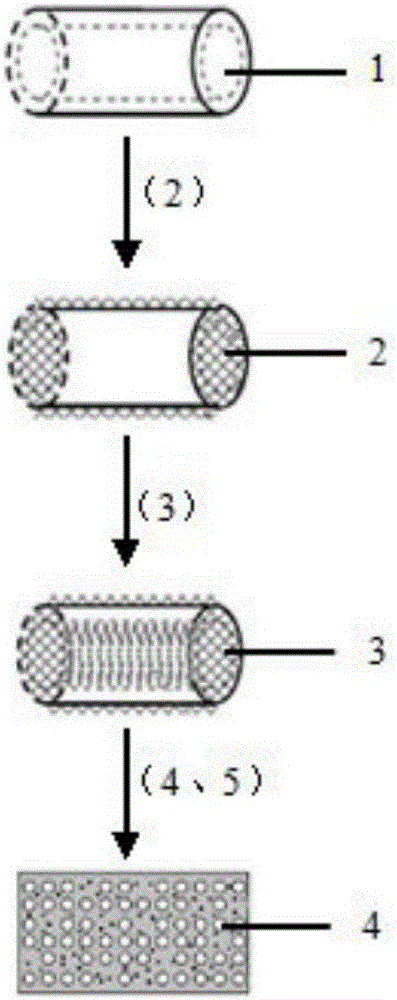

[0026] Such as figure 1 Shown, a kind of preparation method of deodorant type long-acting slow-release plant essential oil polyurethane flexible foam, described preparation method comprises the following steps:

[0027] (1) The halloysite nanotubes are immersed in dilute hydrochloric acid with a mass fraction of 5 to 20% at a temperature of 25 to 80°C for 30 to 60 minutes, filtered, washed, and dried in sequence to obtain activated halloysite nanotubes 1 ;

[0028] (2) Under the protection of an inert gas, dissolve the cyclodextrin in the solvent according to the weight ratio of the cyclodextrin to the solvent 1:5 to 1:10 to obtain a cyclodextrin solution; then add the step ( 1) The obtained activated halloysite nanotubes, the weight ratio of activated halloysite nanotubes to cyclodextrin is 1:3~1:10, mix well to obtain solution a; then add isocyanate and cyclodextrin into solution a The weight ratio with isocyanate is 1:1~1:5, mix evenly to obtain solution b; heat solution ...

Embodiment 1

[0042] A kind of preparation method of deodorant type long-acting slow-release plant essential oil polyurethane soft foam, described preparation method comprises the following steps:

[0043] (1) Dip the halloysite nanotubes in dilute hydrochloric acid with a mass fraction of 20% at a temperature of 25° C. for 60 minutes, filter, wash, and dry in sequence to obtain activated halloysite nanotubes 1;

[0044] (2) Under nitrogen protection, according to the weight ratio of β-cyclodextrin and dimethyl sulfoxide 1:5, β-cyclodextrin was dissolved in dimethyl sulfoxide to obtain a β-cyclodextrin solution; Add the activated halloysite nanotube 1 obtained in step (1) to the β-cyclodextrin solution, the weight ratio of the activated halloysite nanotube to β-cyclodextrin is 1:10, and mix uniformly to obtain solution a; Add 2,4-toluene diisocyanate to solution a, the weight ratio of β-cyclodextrin to 2,4-toluene diisocyanate is 1:1, mix well to obtain solution b; heat solution b to a temp...

Embodiment 2

[0055] A kind of preparation method of deodorant type long-acting slow-release plant essential oil polyurethane soft foam, described preparation method comprises the following steps:

[0056] (1) Dip the halloysite nanotubes in dilute hydrochloric acid with a mass fraction of 5% at a temperature of 80° C. for 30 minutes, filter, wash, and dry in sequence to obtain activated halloysite nanotubes 1;

[0057] (2) Under the protection of argon, dissolve hydroxypropyl β-cyclodextrin in dimethyl sulfoxide according to the weight ratio of hydroxypropyl β-cyclodextrin and dimethyl sulfoxide 1:10 to obtain hydroxypropyl β-cyclodextrin Propyl β-cyclodextrin solution; then add the activated halloysite nanotube 1 obtained in step (1) to the hydroxypropyl β-cyclodextrin solution, activate the halloysite nanotube and hydroxypropyl β-cyclodextrin The weight ratio of essence is 1:3, mix well to get solution a; then add 4,4-diphenylmethane diisocyanate, hydroxypropyl β-cyclodextrin and 4,4-dip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com