Method for decreasing decarburized layers on surfaces of high-carbon-chromium bearing steel wires

A technology of high-carbon chromium bearing steel and decarburization layer, which is applied in the field of bearing steel production, to achieve the effects of reducing cost, good composition uniformity, and reducing the amount of surface grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

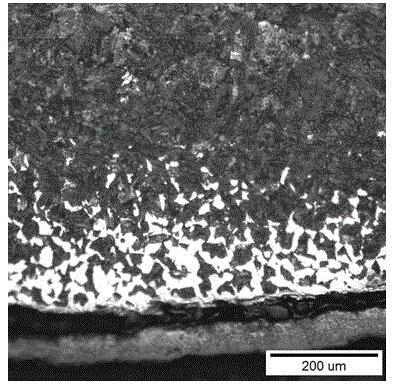

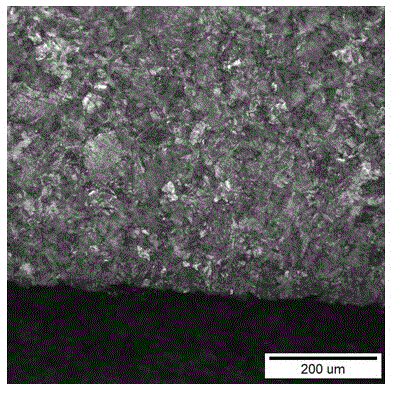

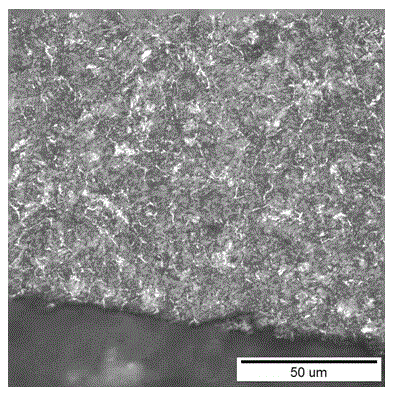

Image

Examples

Embodiment 1

[0030] The molten steel is smelted and continuously cast into a 325mm*280mm cross-section bloom, and its composition by weight percentage is: C1.0%, Si0.24%, Mn0.36%, Cr1.49%, P0.012%, S0.004%, Cu0.03%, Ni0.02% and the rest are iron and unavoidable impurity elements.

[0031] After the bloom is heated and diffused, it is opened into a hot-rolled billet with a cross-section of 160mm*160mm, and the surface of the hot-rolled billet is ground by 1mm.

[0032] The hot-rolled billet is heated in a heating furnace, the temperature of the preheating section is 800°C, the temperature of the heating section is 1040°C, the temperature of the soaking section is 1060°C, the residual oxygen content is 0.5%, and the time in the furnace is 100min.

[0033] After high-speed rolling, the steel billet is spun at 820°C. After spinning, the cooling rate is controlled at 8°C / s, rapidly cooled to below 600°C, and then slowly cooled.

[0034] The GCr15 bearing steel hot-rolled wire rod with a specif...

Embodiment 2

[0036] The molten steel is smelted and continuously cast into a 325mm*280mm cross-section bloom, and its composition by weight percentage is: C0.99%, Si0.23%, Mn0.35%, Cr1.50%, P0.010%, S0.003%, Cu0.03%, Ni0.02% and the rest are iron and unavoidable impurity elements.

[0037] After the bloom is heated and diffused, it is opened into a hot-rolled billet with a cross-section of 160mm*160mm, and the surface of the hot-rolled billet is ground by 1.5mm.

[0038] The hot-rolled billet is heated in a heating furnace, the temperature of the preheating section is 850°C, the temperature of the heating section is 1050°C, the temperature of the soaking section is 1070°C, the residual oxygen content is 0.6%, and the furnace time is 90min.

[0039] After high-speed rolling, the steel billet is spun at 840°C. After spinning, the cooling rate is controlled at 7°C / s, rapidly cooled to below 600°C, and then slowly cooled.

[0040] The GCr15 bearing steel hot-rolled wire rod with a specificati...

Embodiment 3

[0042] Melt steel is smelted and continuously cast into a 325mm*280mm section bloom, the composition of which is: C1.1%, Si0.24%, Mn0.37%, Cr1.47%, P0.013%, S0.002%, by weight percentage, Cu0.03%, Ni0.02% and the rest are iron and unavoidable impurity elements.

[0043] After the bloom is heated and diffused, it is opened into a hot-rolled billet with a section of 160mm*160mm, and the surface of the hot-rolled billet is ground by 2mm.

[0044] The hot-rolled billet is heated in a heating furnace, the temperature of the preheating section is 840°C, the temperature of the heating section is 1030°C, the temperature of the soaking section is 1060°C, the residual oxygen content is 0.5%, and the furnace time is 95min.

[0045] After high-speed rolling, the steel billet is spun at 850°C, and after spinning, it is rapidly cooled to below 600°C at a cooling rate of 6°C / s for slow cooling.

[0046] The GCr15 bearing steel hot-rolled wire rod with a specification of Φ20mm produced by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com