Earthquake-resistant structure for dam crest of high earth-rock dam and construction method of earthquake-resistant structure

A technology for high earth-rock dams and anti-seismic structures, applied in filling, dams, barrages, etc., can solve the problems of geogrid strength loss, complicated construction process, grid node stripping, etc., to enhance the overall anti-seismic performance and improve the overall anti-seismic non-toxic, good anti-rolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

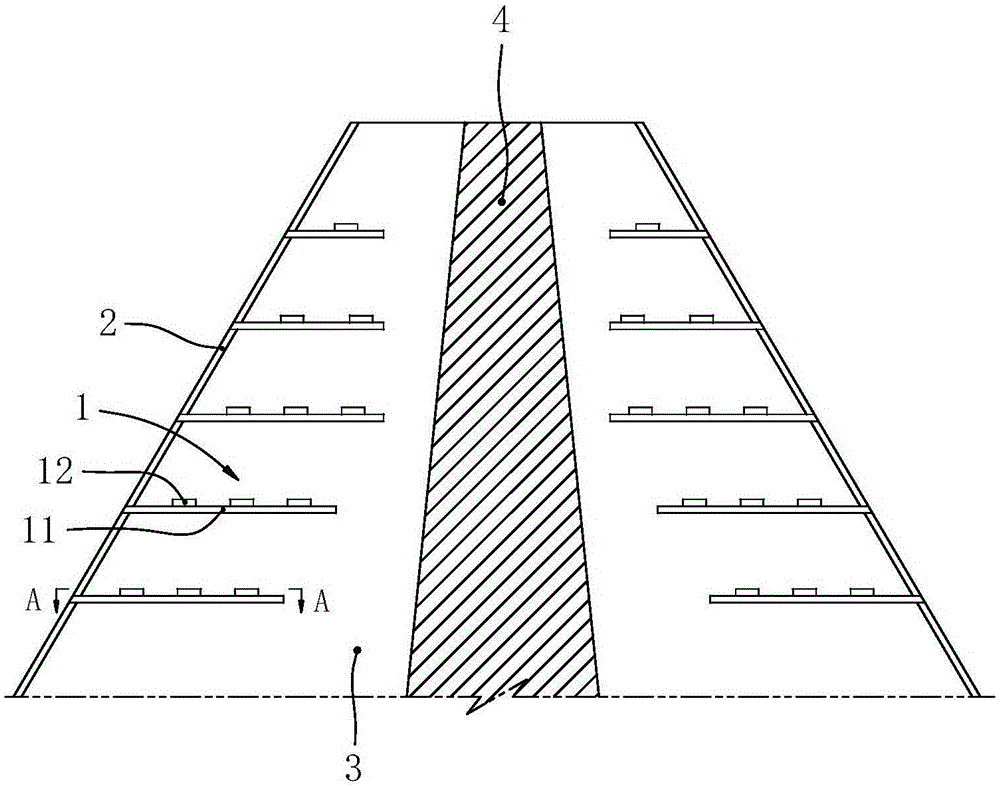

[0041] The design elevation of a core rockfill dam is H=300m, the slope ratios of the upstream and downstream are 1:2.0 and 1:1.9 respectively, and the crest width is 16m;

[0042] a. Layer-by-layer filling and rolling of high earth-rockfill dam body rockfill material 3 to the 225-240m of the design elevation of the dam body;

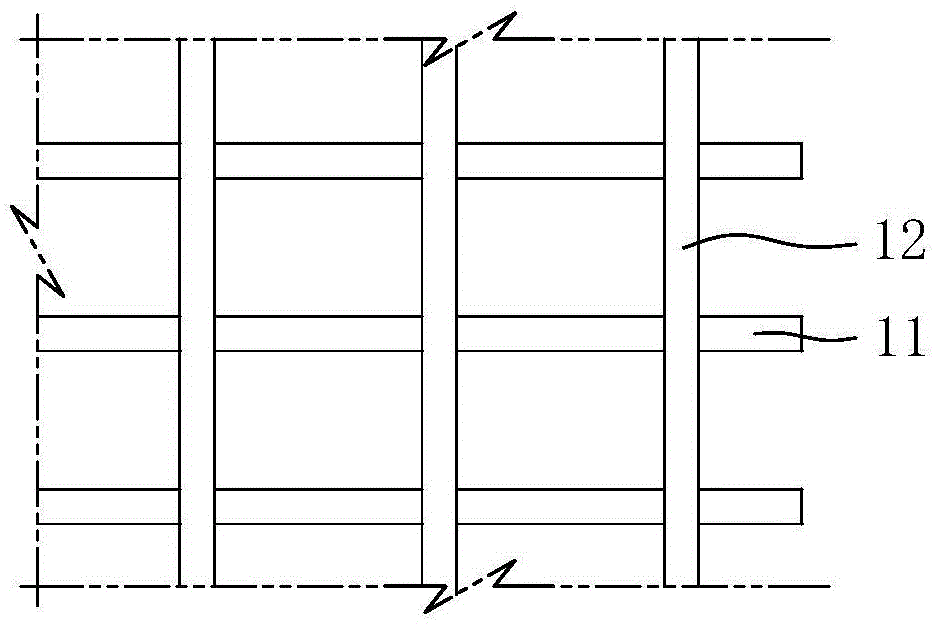

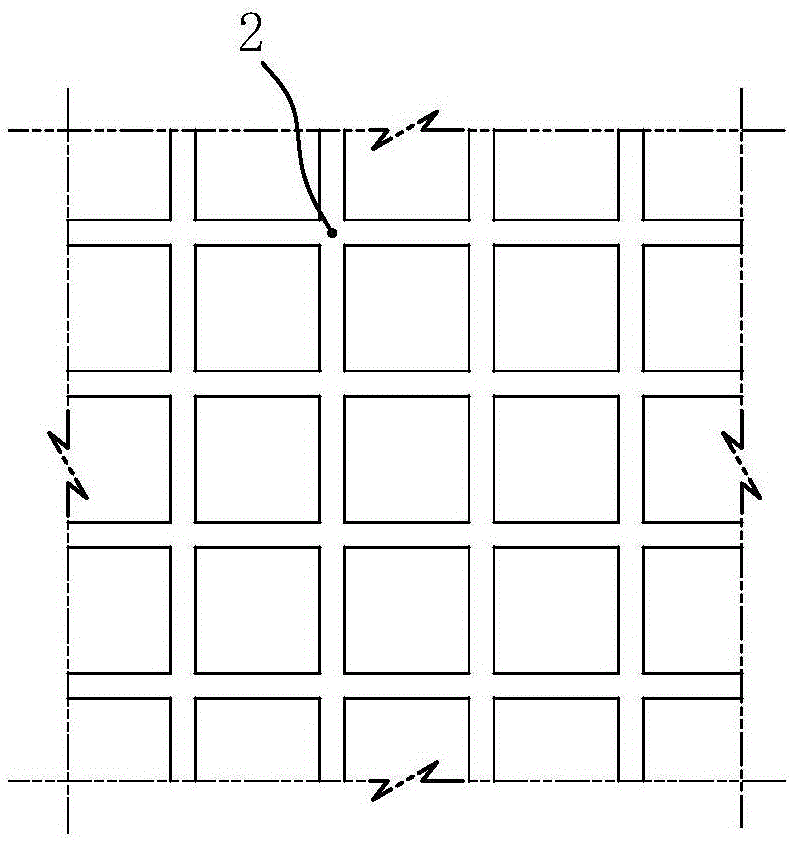

[0043] b. Use a stainless steel sheet with a width of 50mm×thickness of 6mm to make the flat sheet 11 along the river and the flat sheet 12 in the axial direction of the dam; lay the flat sheet 11 along the river and the flat sheet 12 in the axial direction of the dam on the rolled rockfill material 3, The flat piece 11 along the river and the flat piece 12 in the axial direction of the dam are respectively arranged along the flow direction of the river and the length direction of the high earth-rock dam; the flat piece 11 along the river and the flat piece 12 in the axial direction of the dam are connected to form a frame 1; Wherein, there are at least...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com