Light heat insulation and decoration integrated building board

A light-weight technology for building panels, applied in the field of building decoration and thermal insulation materials, can solve problems such as wasting natural resources, increasing wall loads, and cumbersome engineering construction, and achieves the effects of high-efficiency construction, shortened construction period, high-quality waterproof, fireproof, and energy-saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

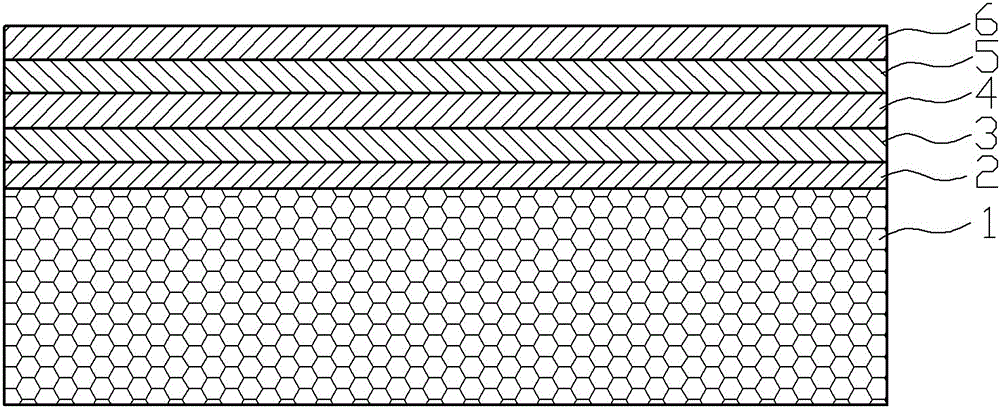

[0010] Such as figure 1 As shown, the lightweight thermal insulation and decoration integrated building board includes a lightweight thermal insulation base layer 1, an inorganic strong adhesive layer 2, a grid cloth 3, an inorganic composite water-resistant adhesive layer 4, a cement glass fiber cloth 5 and a decorative layer 6 , between the lightweight thermal insulation base layer 1 and the mesh cloth 3 and between the mesh cloth 3 and the cement glass fiber cloth 5 are respectively bonded with the inorganic strong adhesive layer 2 and the inorganic composite anti-water surface adhesive layer 4, and the facing decorative layer 6 Coated on the cement glass fiber cloth 5 surface.

[0011] The lightweight thermal insulation base layer 1 is EPS or XPS or the like.

[0012] The finish decoration layer 6 adopts real stone paint, rock flake paint or latex paint.

[0013] The inorganic strong adhesive layer (2) consists of 48 to 52 parts of high alumina cement, 390 to 410 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com