Non-intrusive ultrasonic detection method of mud flow rate in deepwater drilling riser

A deep-sea drilling, non-invasive technology, applied in the direction of fluid velocity measurement, velocity/acceleration/shock measurement, measuring devices, etc., can solve the problems of short gas intrusion treatment time, high cost, large ultrasonic attenuation, etc., and achieve detection speed Fast, high accuracy, timely response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0040] The invention provides a non-invasive ultrasonic detection method for mud flow velocity in a deep-sea drilling riser, comprising the following steps:

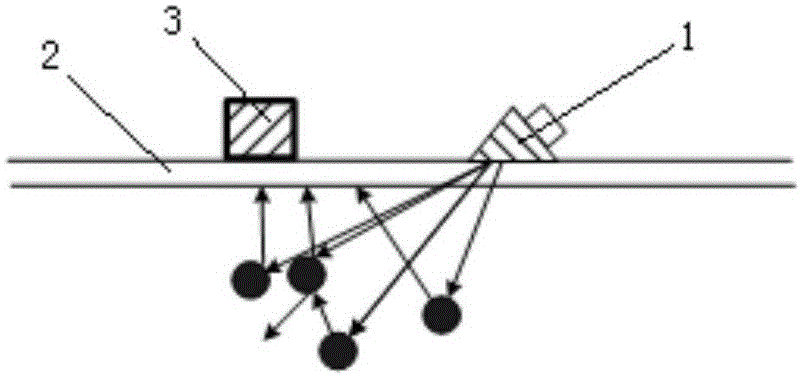

[0041] 1) if figure 1 As shown, the emission sensor 1 is attached to the pipe wall of the riser 2 at an angle of π / 18-4π / 9. The transmitting sensor 1 transmits ultrasonic waves with a frequency of 40KHz-200KHz in a direction consistent with or opposite to the flow velocity of the mud in the riser 2 . The receiving sensor 3 is installed perpendicular to the direction of the pipe wall of the riser 2 at the point with the largest amplitude on the path of the ultrasonic propagation direction.

[0042] 2) Perform corresponding filtering, amplification and other signal processing on the collected actual working signal of the transmitting sensor 1 to obtain the actual working signal frequency f of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com